MMCC direct railway power compensator and control method thereof

A power compensator, power compensation technology, applied in reactive power adjustment/elimination/compensation, reactive power compensation, AC network voltage adjustment, etc., can solve the problems of bulky, heavy and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

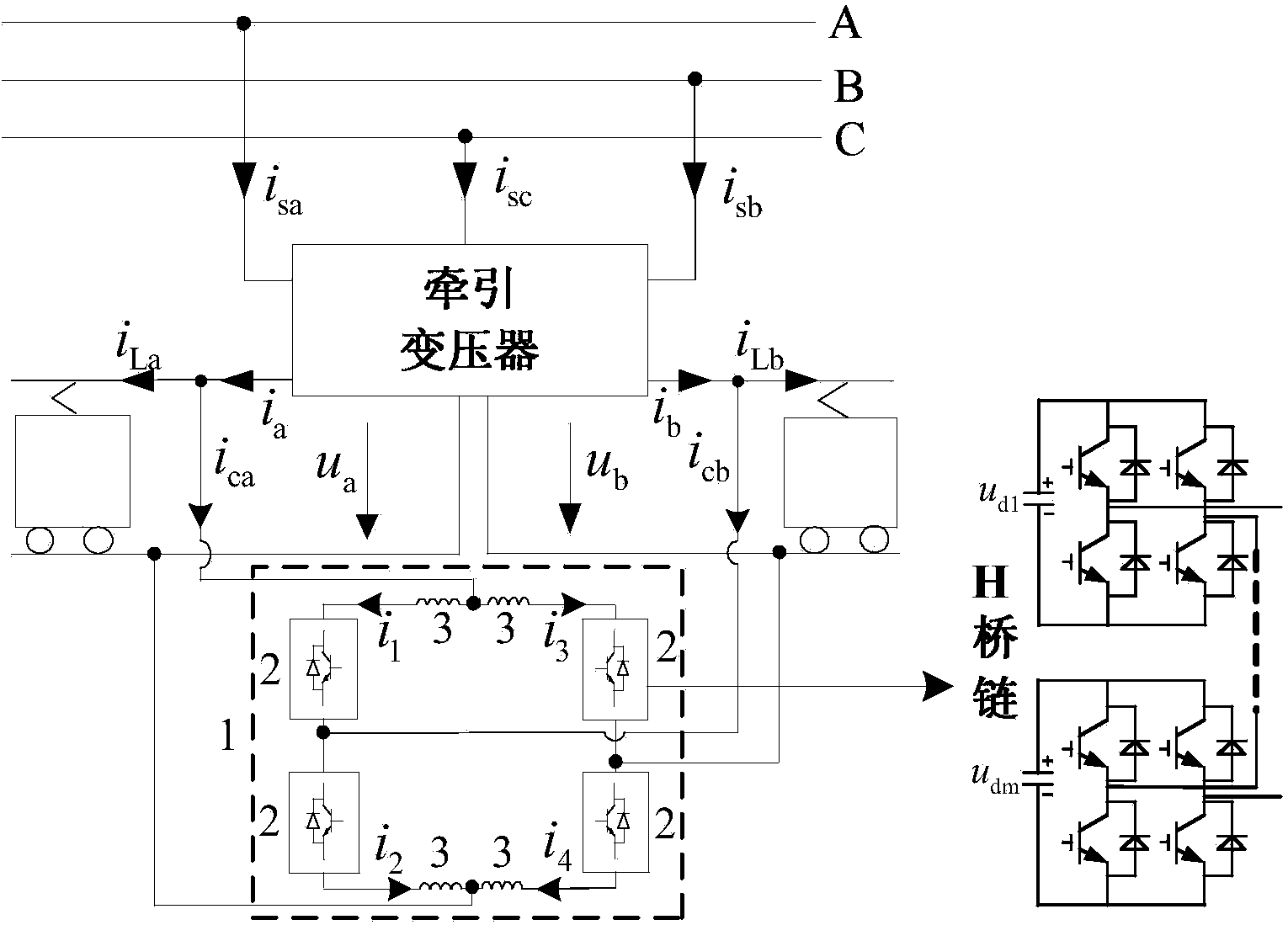

[0032] like figure 2 As shown, the MMCC type direct railway power compensator according to an embodiment of the present invention is composed of four sides; each side is composed of an H bridge chain 2 and a filter inductor 3; the H bridge chain 2 is formed by connecting multiple H bridge units in series ; The four intersections of the quadrilateral are divided into two groups according to the diagonals, and the two groups of intersections are respectively connected to the two traction power supply arms through cables. The device forms a quadrilateral single-phase AC-AC converter by using multi-level cascaded converters, and can be directly connected to the traction power supply arm without a step-down transformer. At the same time, there is no need for a DC link in the middle, and the two-way conversion and flow of power can be directly realized, and at the same time, the reactive power generated by the locomotive load of the traction power supply arm can be compensated. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com