Double-end universal fast mounting instrument valve

A quick-installation valve and valve body technology, applied to the valve details, valve device, valve shell structure, etc., can solve the problems of easy leakage of raw material belt, difficult to adjust the direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific implementation mode one (sufficient space for instrument installation)

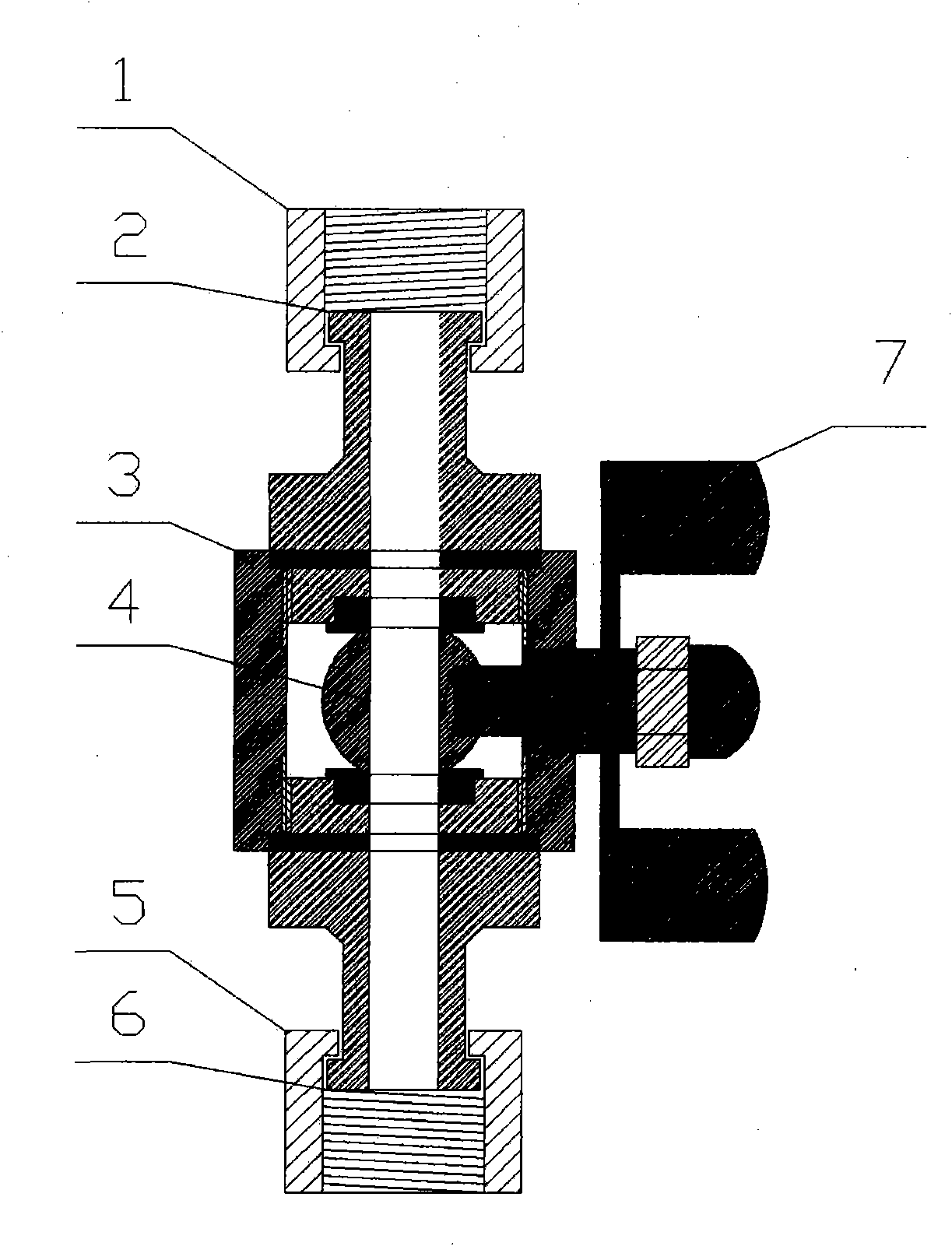

[0009] As shown in the figure, it is a double-head universal quick-fit meter valve. After the lower sealing ring (6) is added with a PTFE gasket, it is connected to the thread on the pipeline through the lower connection adjusting nut (5) to tighten the lower connection adjustment Nut (5): After adding the PTFE gasket to the upper sealing ring (2), connect it to the instrument to be installed through the upper connecting adjusting nut (1), and tighten the upper connecting adjusting nut (1). When the direction of the operating handle (7) is not convenient for the staff to operate, the direction of the valve body (3) can be adjusted until it is adjusted to the appropriate direction. When the direction of the installed instrument surface is not suitable for the staff to observe the display data of the instrument, the upper connection can be adjusted Adjust the direction of the nut (1) until it i...

specific Embodiment approach 2

[0010] Specific implementation mode 2 (Limited instrument installation space)

[0011] As shown in the figure, it is a double-head universal quick-fit meter valve. After the upper sealing ring (2) is added with a PTFE gasket, it is connected to the instrument to be installed through the upper connection adjustment nut (1), and the upper connection adjustment is tightened. Nut (1). After adding the PTFE gasket to the lower sealing ring (6), connect the lower connection adjusting nut (5) to the threaded port on the pipeline, and tighten the lower connecting adjusting nut (5). When the direction of the operating handle (7) is not convenient During operation, the staff can adjust the direction of the valve body (3) until it is adjusted to the proper direction. When the surface direction of the installed instrument is not suitable for the staff to observe the display data of the instrument, the direction of the upper connecting adjustment nut (1) can be adjusted until Adjust to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com