Spherical hinge capable of realizing rotation angle measurement and measurement method of rotation angle

A technology of rotation angle and ball hinge, which is applied in the field of ball hinges, can solve problems such as difficulty in reducing the size of the structure, impossibility of embedding, and affecting the quality of optical imaging, so as to improve resolution and measurement accuracy, overcome interference and influence, and greatly promote the value of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

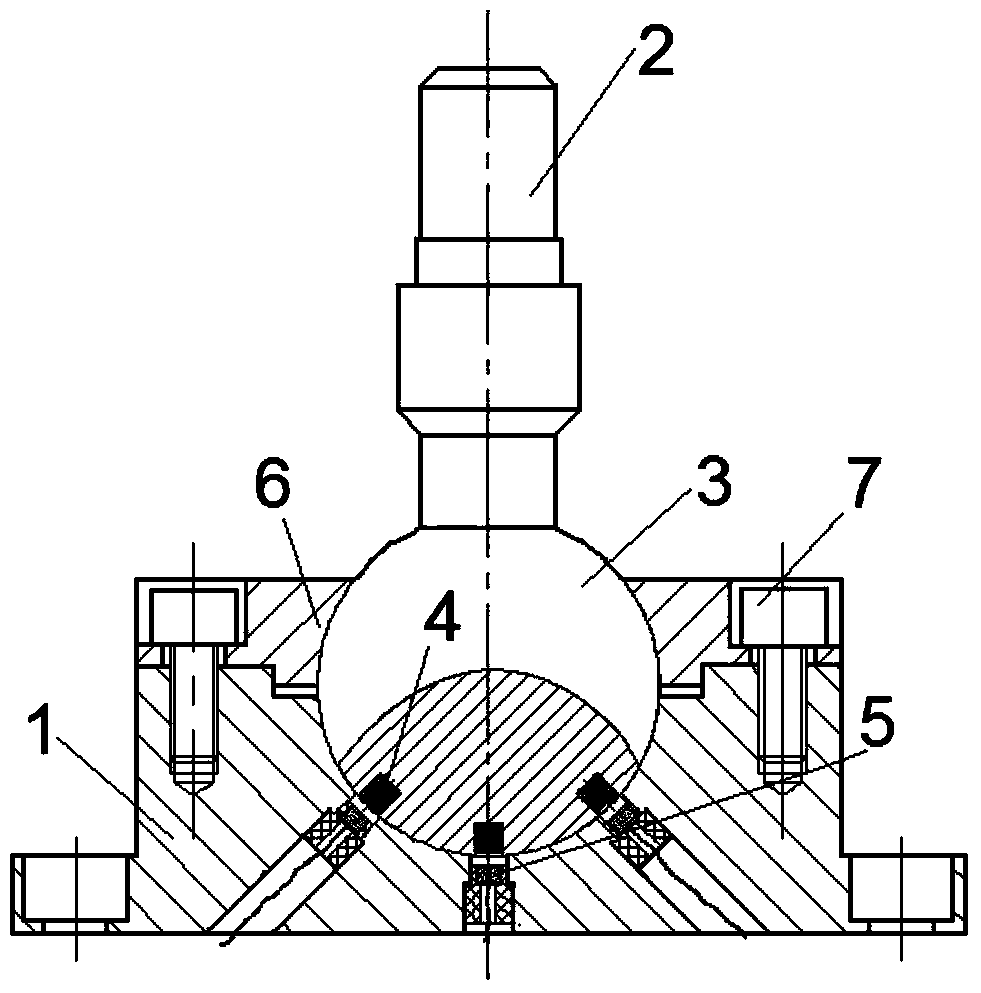

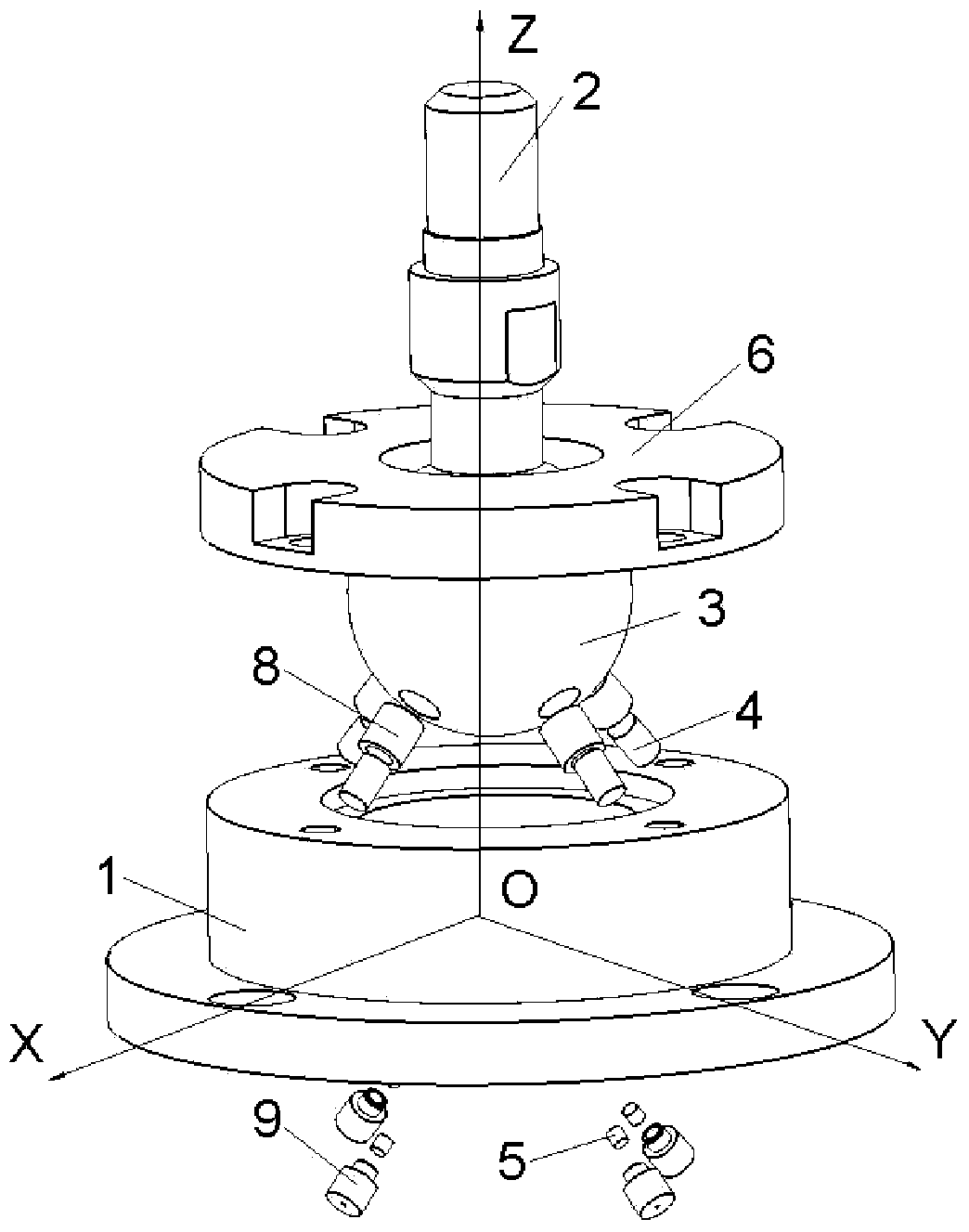

[0028] see figure 1 , figure 2 with image 3 , the structural form of the ball hinge that can realize the measurement of the rotation angle in this embodiment is:

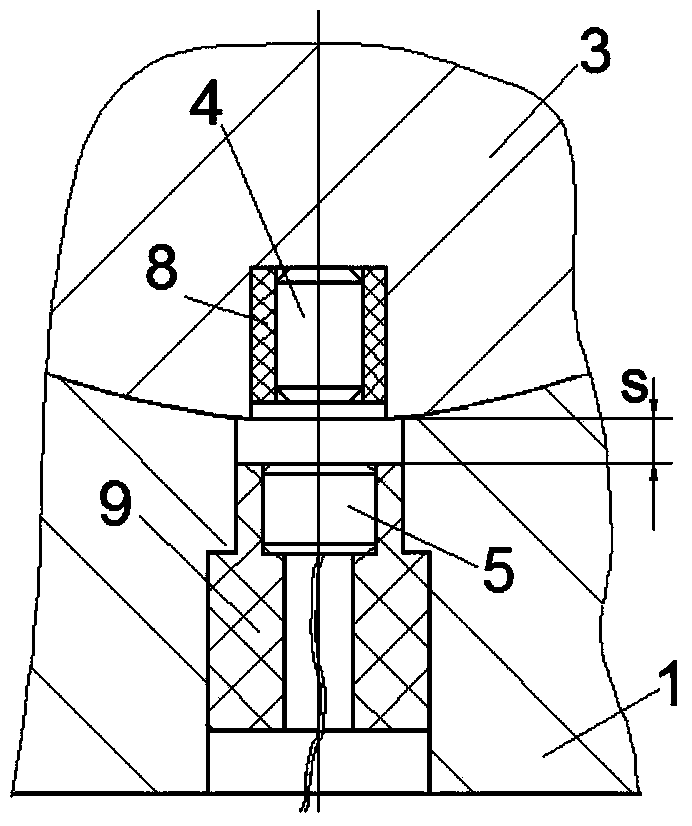

[0029] A ball seat with a ball socket inside is formed by the base 1 and the end cover 6, and the ball crown of the ball socket is formed as an opening on the end cover 6; the ball head 3 is placed in the ball socket and exposed at the opening of the end cover 6 The ball cap is connected to the ball hinge rod 2 on the top surface of the ball cap of the ball head 3; the ball head 3 is concentric with the ball socket, and the ball head 3 can rotate concentrically with respect to the ball socket.

[0030] A permanent magnet 4 is embedded on the lower hemispherical surface of the ball head 3, and m permanent magnets 4 are evenly distributed on the lower hemispherical surface of the ball head 3; a magnetic effect sensor 5 is embedded on the surface of the ball socket, and there are n The magnetic effect sensors 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com