Self-propelled type temporary support and anchor support machine for coal mine roadway

A coal mine roadway and temporary support technology, applied to temporary shields, mining equipment, slitting machinery, etc., can solve problems such as low operating efficiency, hidden dangers to personal safety, and impact on the excavation efficiency of fully mechanized excavators, so as to improve labor efficiency, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

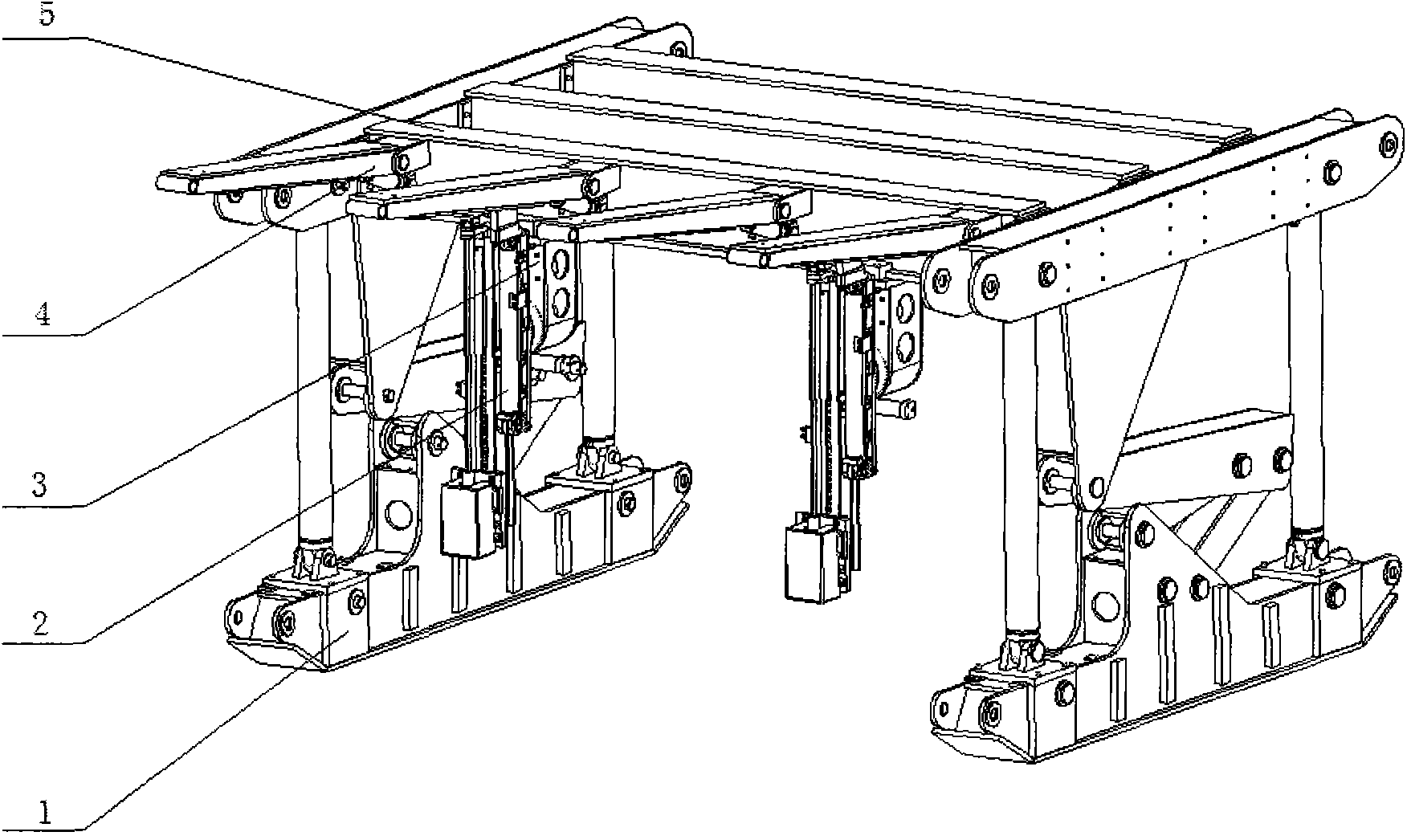

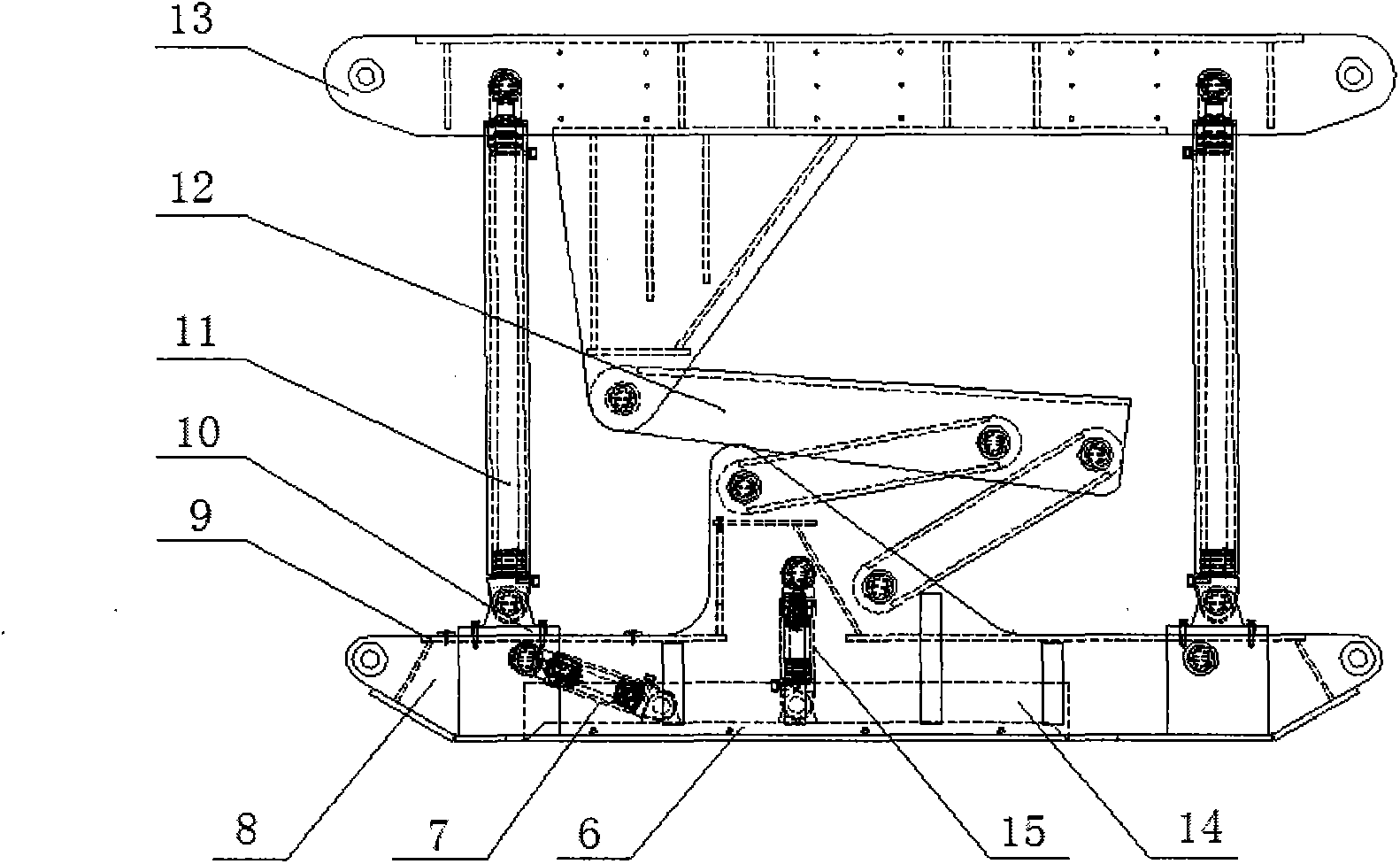

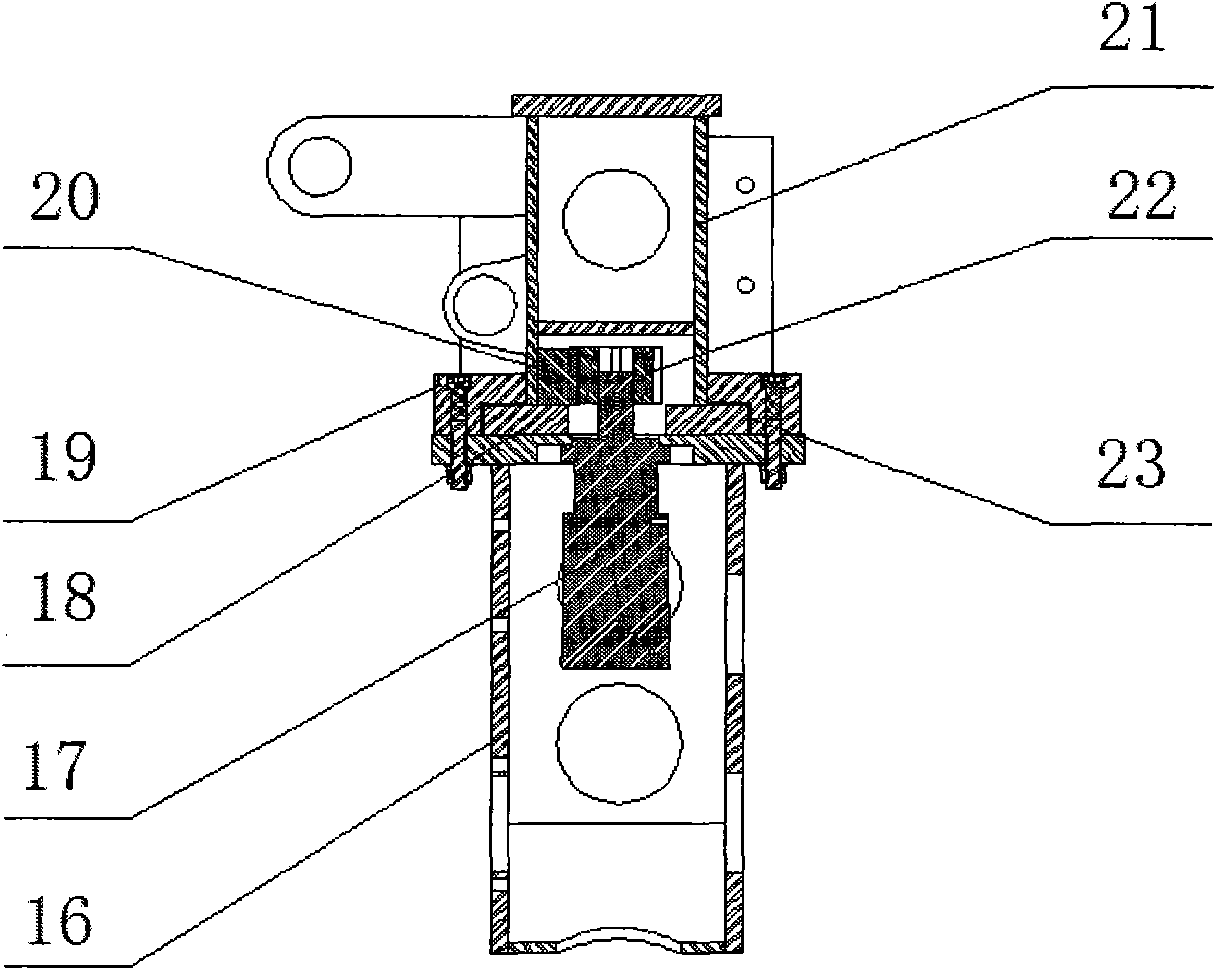

[0029] like Figure 1 to Figure 12 As shown, the self-propelled coal mine roadway temporary support anchor machine of the present invention includes a walking support module (1), a supporting beam module (5), an advanced cover beam module (4), a bolter module (2) and a drilling rig walking module (3), the walking support module (1) includes a track shoe (6), a track shoe baffle plate (14), a walking cylinder 1 (7), a walking cylinder 2 (15), a support base (8), a guide connecting rod (12), supporting oil cylinder (11), supporting oil cylinder base (10), top beam (13) and cover plate (9), and one track baffle plate (14) is respectively fixed by screws on both sides of the track shoe (6) , the track baffle (14) acts as the track of the track (6) when the whole machine is walking, and reduces muddy water from enteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com