Composition for highly transparent polyvinyl chloride heat-shrinkable film and preparation method thereof

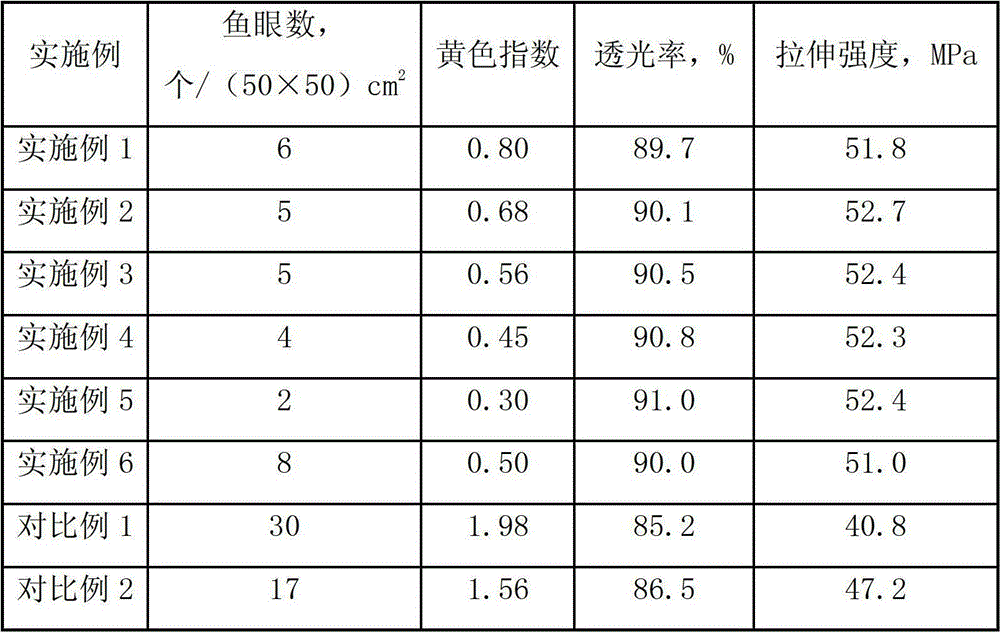

A polyvinyl chloride and heat shrinkable film technology, applied in the field of polymer materials, can solve the problems of many fish eyes in the heat shrinkable film, lower product quality, and yellow color of the finished heat shrinkable film, so as to improve the plasticizing effect and increase the light transmission efficiency, quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

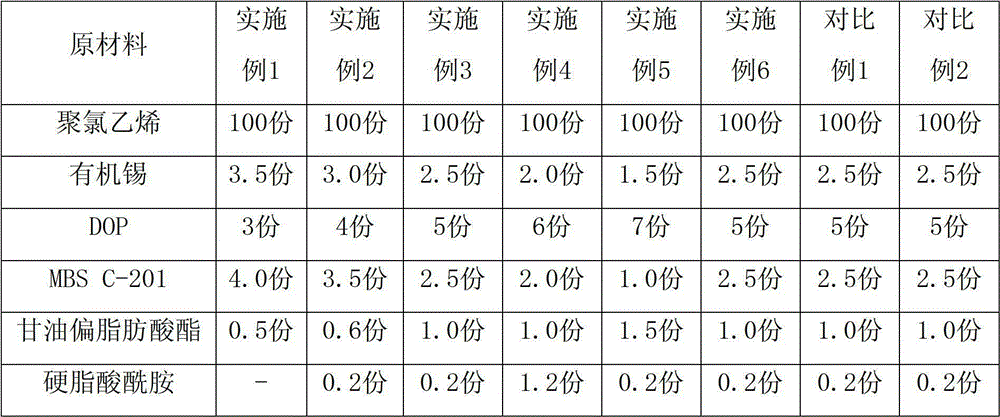

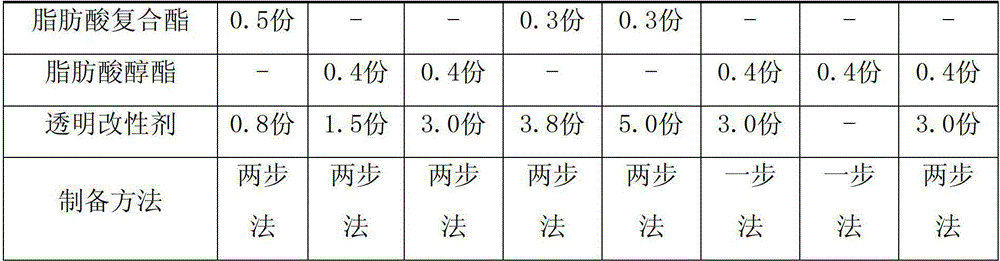

Embodiment 1

[0026] Step 1. Weigh 0.5 part of acrylate (ACR), 0.1 part of paraffin wax, 0.1 part of stearic acid, and 0.1 part of polymethylphenylsiloxane into a high-speed mixer (680-1400r / min) and stir at a high speed. When the temperature rises to 100-110°C, put the mixture in the high-speed mixer into a low-speed mixer (85r / min) to stir and cool, and when the temperature drops to 40-50°C, the released material is PVC heat shrinkable film Use a transparency modifier.

[0027] Step 2. Weigh 100 parts of polyvinyl chloride resin with an average degree of polymerization of 700±50, 3.5 parts of octyltin mercaptide, 3 parts of dioctyl phthalate, and methyl-butadiene-styrene copolymer of methacrylate C-2014.0 parts, 0.5 parts of glycerin partial fatty acid ester, 0.5 part of fatty acid complex ester, and 0.8 part of transparency modifier. Put the weighed components into a high-speed mixer (680-1400r / min) and stir at a high speed. When the temperature rises to 110-120°C, put the mixture in th...

Embodiment 2

[0029] Step 1. Weigh 1.0 parts of acrylate (ACR), 0.15 parts of microcrystalline wax, 0.15 parts of oleic acid, and 0.2 parts of polymethylphenylsiloxane into a high-speed mixer (680-1400r / min) and stir at high speed. When the temperature rises to 100-110°C, put the mixture in the high-speed mixer into a low-speed mixer (85r / min) to stir and cool, and when the temperature drops to 40-50°C, the released material is polyvinyl chloride heat shrinkage Transparency modifier for films.

[0030] Step 2. Weigh 100 parts of polyvinyl chloride resin with an average degree of polymerization of 800±50, 3.0 parts of octyltin mercaptide, 4 parts of dioctyl phthalate, and methyl-butadiene-styrene copolymer of methacrylate 3.5 parts of C-201, 0.6 parts of glycerin partial fatty acid ester, 0.2 part of stearic acid amide, 0.4 part of fatty acid alcohol ester, and 1.5 parts of transparency modifier. Put the weighed components into a high-speed mixer (680-1400r / min) and stir at a high speed. Wh...

Embodiment 3

[0032] Step 1. Weigh 1.5 parts of acrylate (ACR), 0.3 parts of microcrystalline wax, 0.5 parts of stearic acid, and 0.7 parts of polymethylphenylsiloxane into a high-speed mixer (680-1400r / min) and stir at high speed , when the temperature rises to 100-110°C, put the mixture in the high-speed mixer into a low-speed mixer (85r / min) to stir and cool, and when the temperature drops to 40-50°C, the material released is polyvinyl chloride heat. Clarity modifier for shrink film.

[0033] Step 2. Weigh 100 parts of polyvinyl chloride resin with an average degree of polymerization of 1000±50, 2.5 parts of methyl tin mercaptide, 5 parts of dioctyl phthalate, methyl-butadiene-styrene methacrylate Copolymer C-2012.5 parts, glycerin partial fatty acid ester 1.0 part, stearic acid amide 0.2 part, fatty acid alcohol ester 0.4 part, transparency modifier 3.0 parts. Put the weighed components into a high-speed mixer (680-1400r / min) and stir at a high speed. When the temperature rises to 100-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com