Textile bobbin

A bobbin and mandrel technology, applied in the field of textile bobbins, can solve the problems of resource waste, non-adjustable, easy damage, etc., and achieve the effects of avoiding winding and knotting, improving service life, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

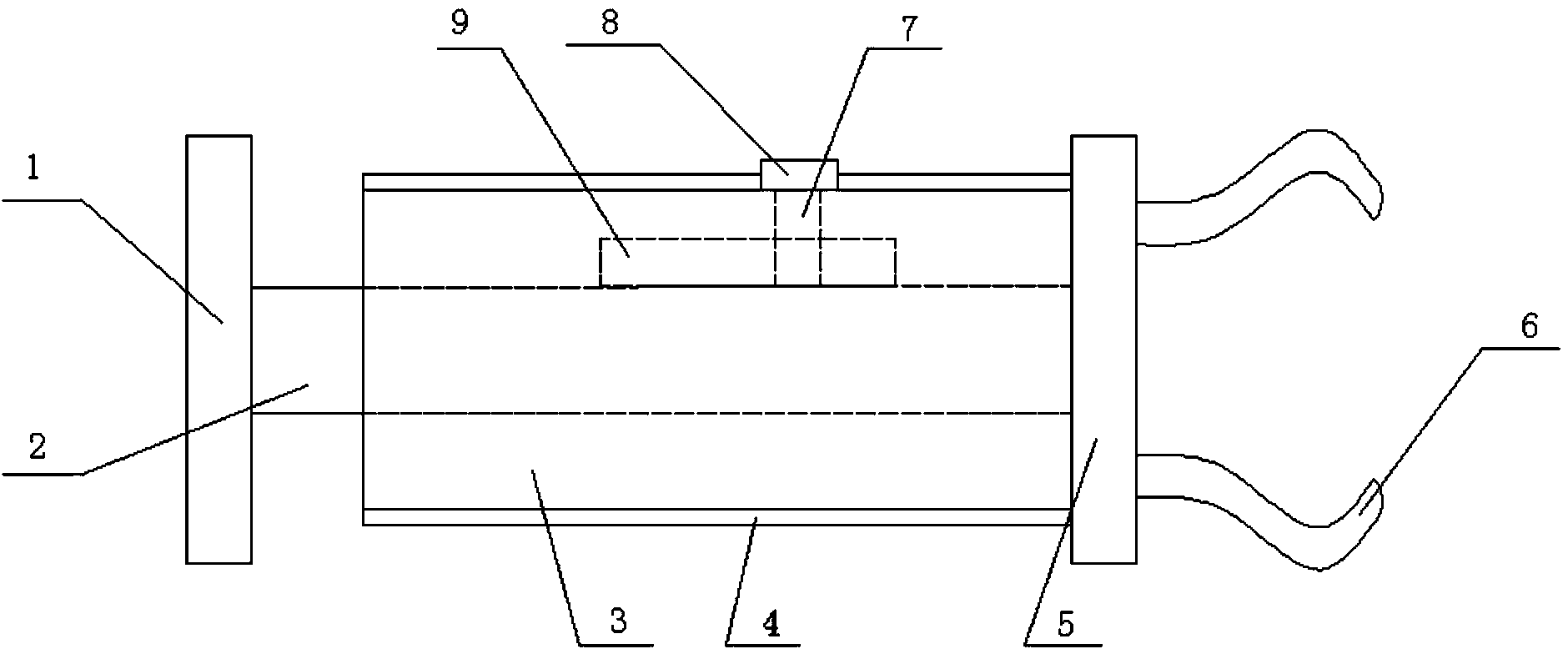

[0014] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown, the textile yarn bobbin of the present invention includes a turntable 1, a mandrel 2, a bobbin 3, a wear-resistant sleeve 4, a side plate 5, a whisker 6, a screw rod 7, a lock nut 8, and a chute 9; The bobbin is sleeved on the periphery of the mandrel, and the two ends of the mandrel are respectively equipped with a turntable and a side plate; The fasteners are fastened or installed with a slot-bump structure; the mandrel is provided with a chute, and the bobbin is provided with a slit corresponding to the chute, and one end of the screw passes through the slit and stops at the chute The bottom of the groove and the other end are equipped with a lock nut, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com