Automatic blank arranging machine

A billet arranging machine, automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of uneven placement of billets, low degree of automation, poor operation stability, etc., to achieve good material coding effect, high degree of automation, non-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

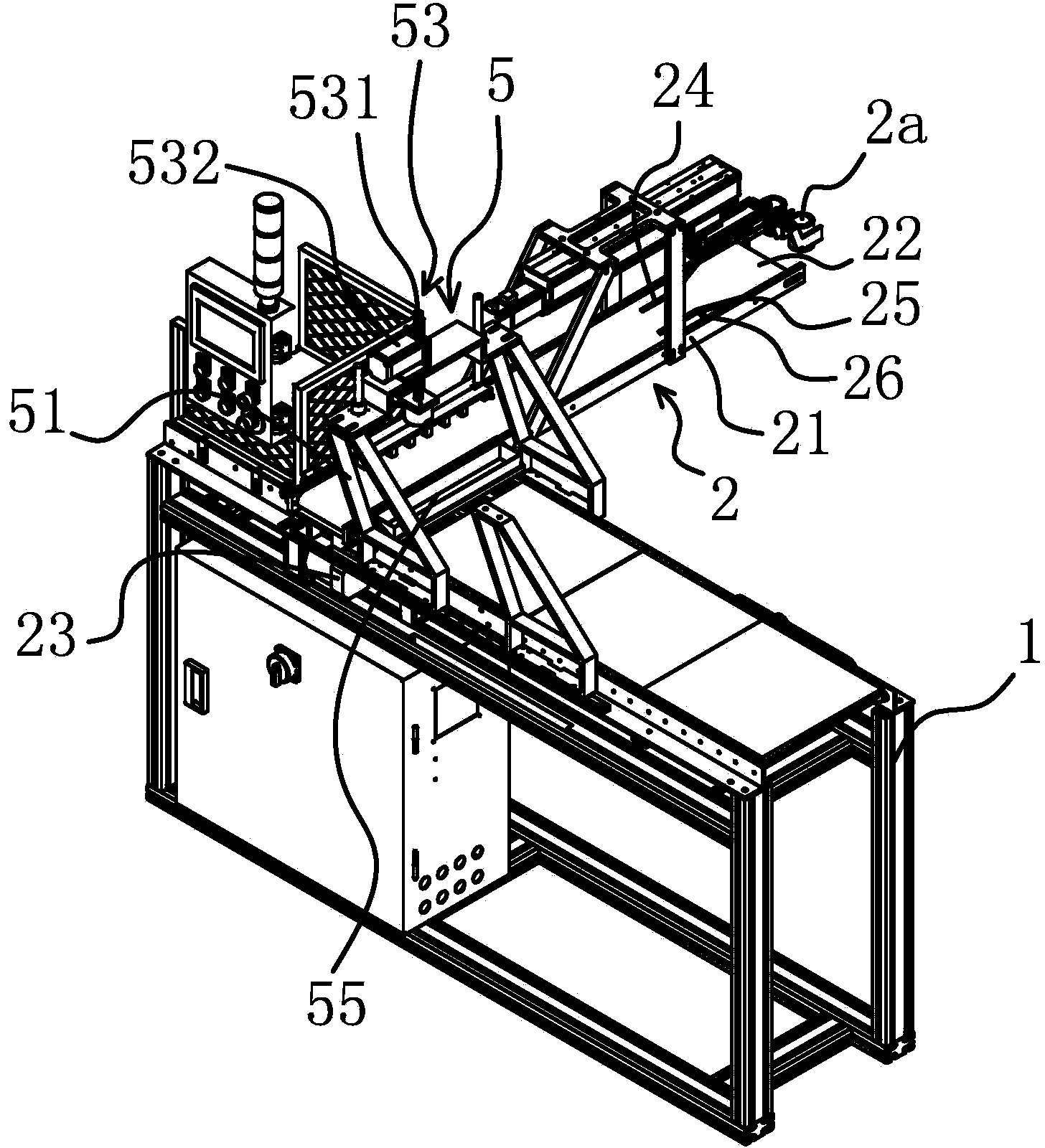

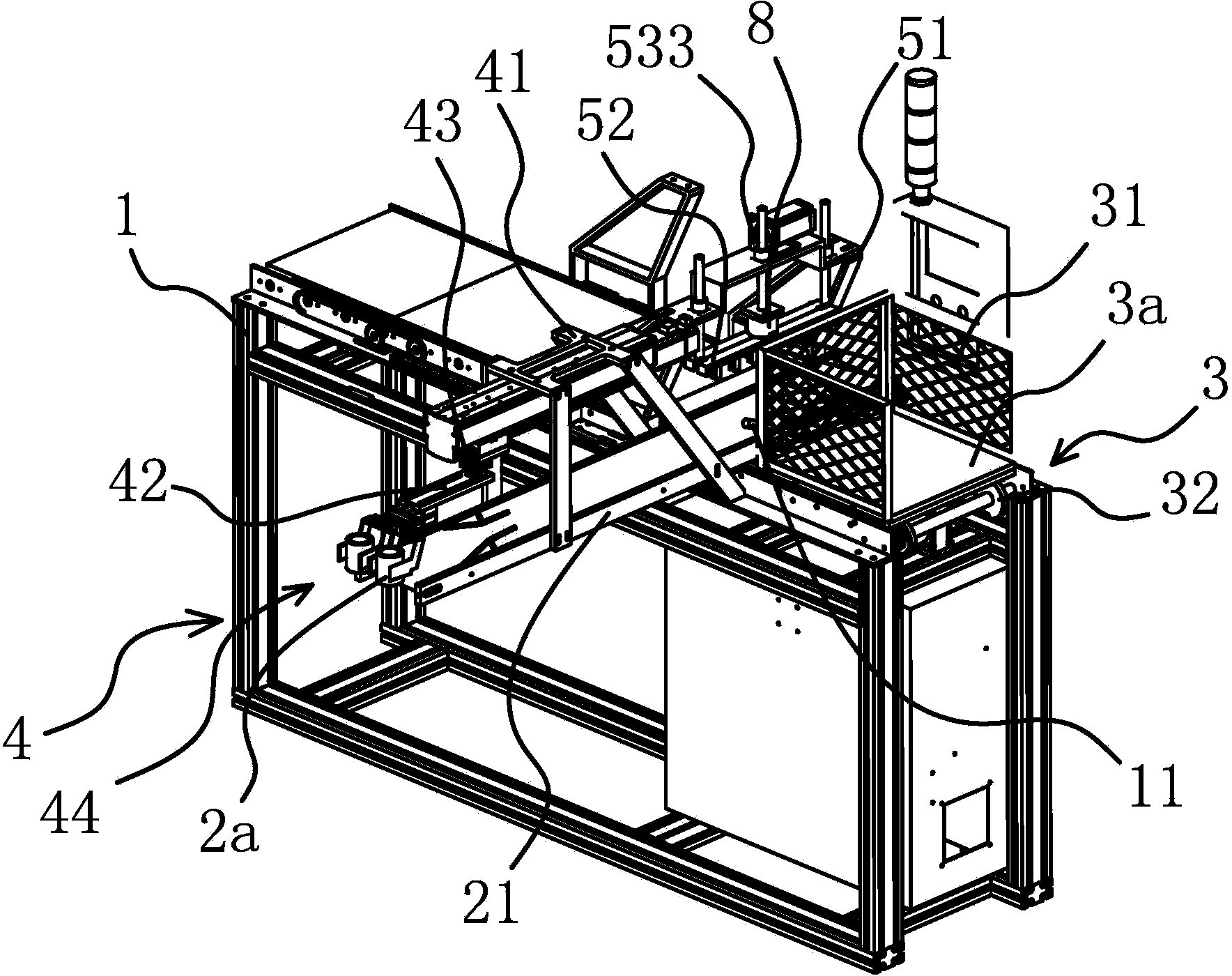

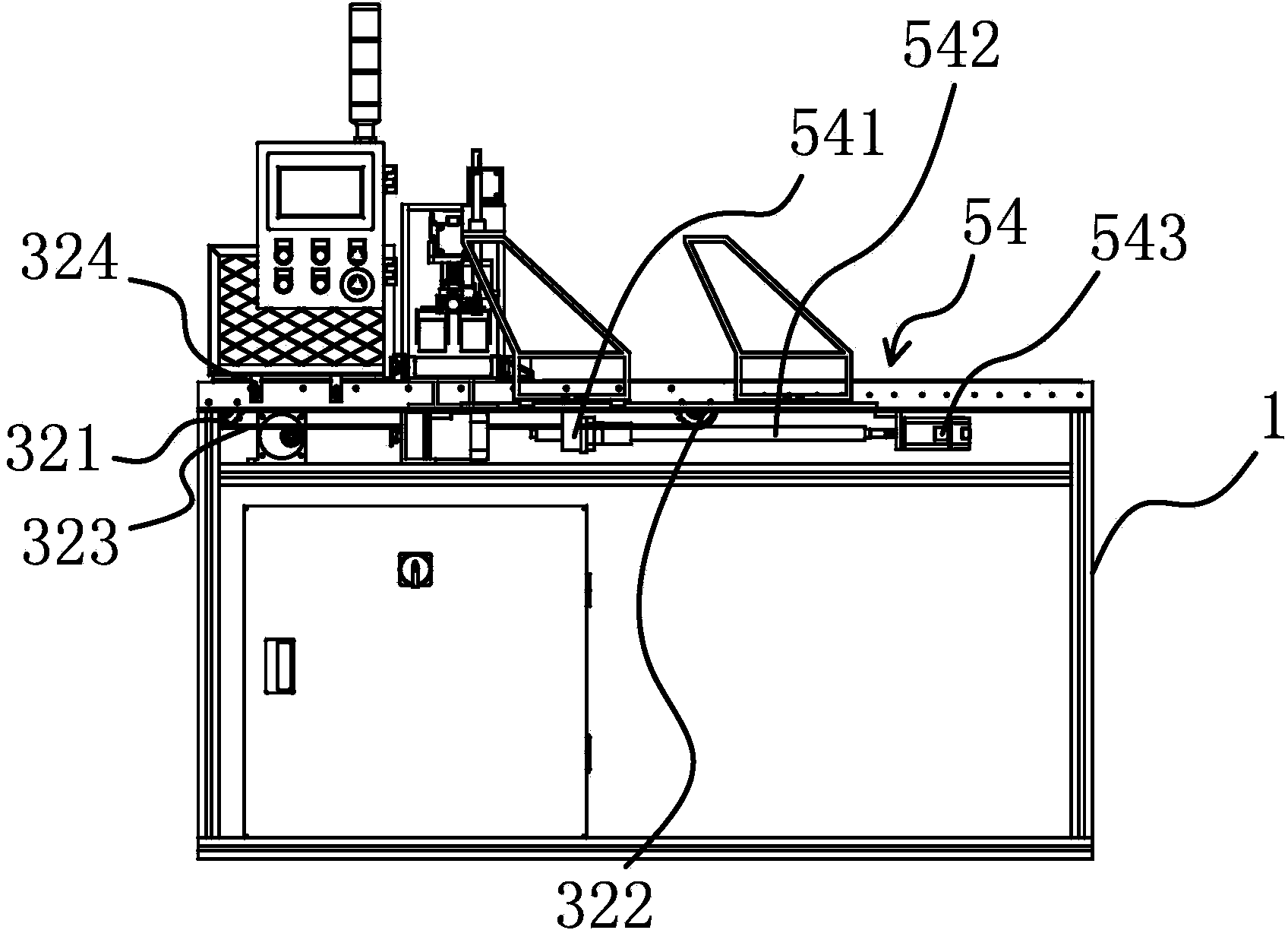

[0030] Such as Figure 1-6 As shown, the automatic billet unloading machine includes a frame 1, which is provided with a blank conveying mechanism 2 for conveying the blank 2a and a pallet conveying mechanism 3 for conveying the tray 3a on the frame 1, and one end of the blank conveying mechanism 2 is provided with a The blank 2a is transferred from the peripheral equipment to the blank taking device 4 in the blank conveying mechanism 2, the other end of the blank conveying mechanism 2 extends above the tray conveying mechanism 3, and the frame 1 is equipped with a Move back and forth and transfer the blank 2a on the blank conveying mechanism 2 and stack it to the stacking device 5 in the pallet 3a on the pallet conveying mechanism 3, and transfer the blank 2a to one end of the blank conveying mechanism 2 through the blank removing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com