Automatic plate roller loading and unloading device of electric carving machine

A technology of automatic loading and unloading, electric engraving machine, applied in the direction of decorative art, processing models, etc., can solve the problems of injury, reduce the service life of electric engraving machine, operator personal and other problems, to improve work safety rate and work efficiency, reduce the chance of rework , the effect of saving resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

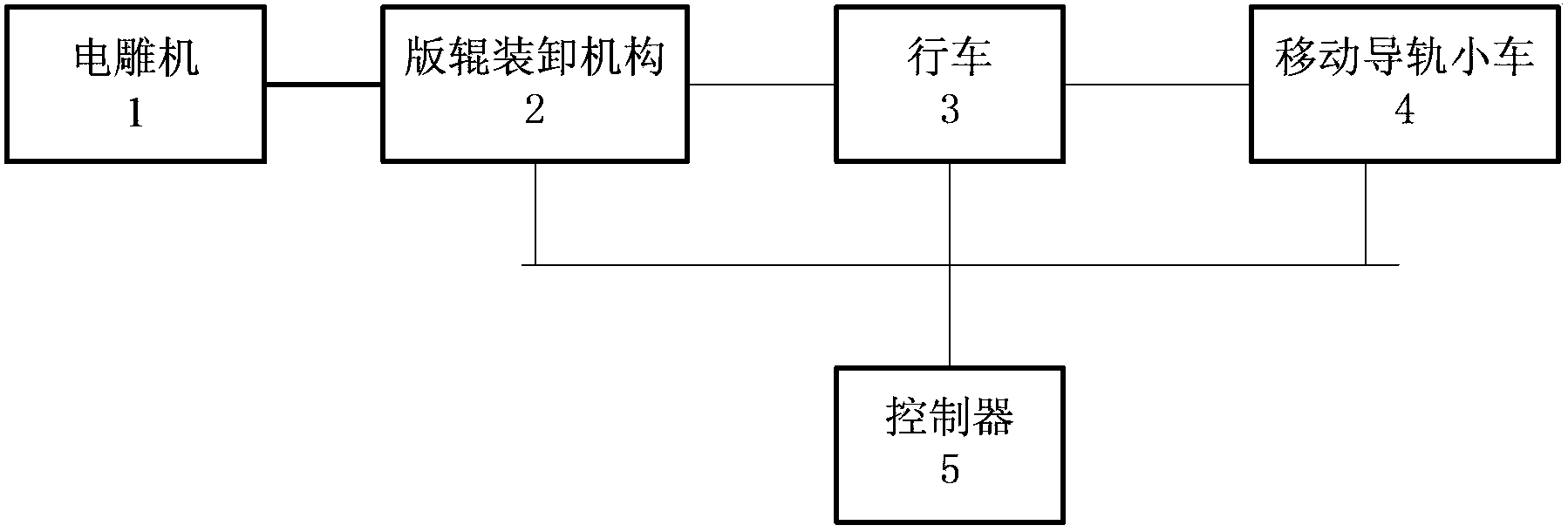

[0012] Such as figure 1 As shown, a device for automatically loading and unloading plate rollers of an electric engraving machine includes a plate roller loading and unloading mechanism 2, a driving car 3, a moving guide trolley 4 and a controller 5, and the plate roller loading and unloading mechanism 2 is fixed on the electric engraving machine 1, and the The above-mentioned controller 5 is respectively connected with the plate roller loading and unloading mechanism 2, the driving car 3, and the mobile guide rail trolley 4;

[0013] The controller 5 controls the plate roller loading and unloading mechanism 2 to put the plate roll to be engraved into the engraving position of the electric engraving machine 1, and the electric engraving machine 1 engraves the plate roller. After the engraving is completed, the controller 5 controls the plate roller loading and unloading mechanism 2 to place The plate roll is raised, and the controller 5 controls the traveling carriage 3 to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com