The Method of Machining the Outer Circle of the Sector Plate Using the Split Backing Plate

A fan-shaped plate and split-type technology, which is applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve problems such as unguaranteed assembly accuracy, unreliable positioning, and out-of-tolerance dimensions of the outer circle of four fan-shaped plates. Achieve the effect of solving the out-of-tolerance of the outer circle size, avoiding electric welding, and ensuring the stability of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

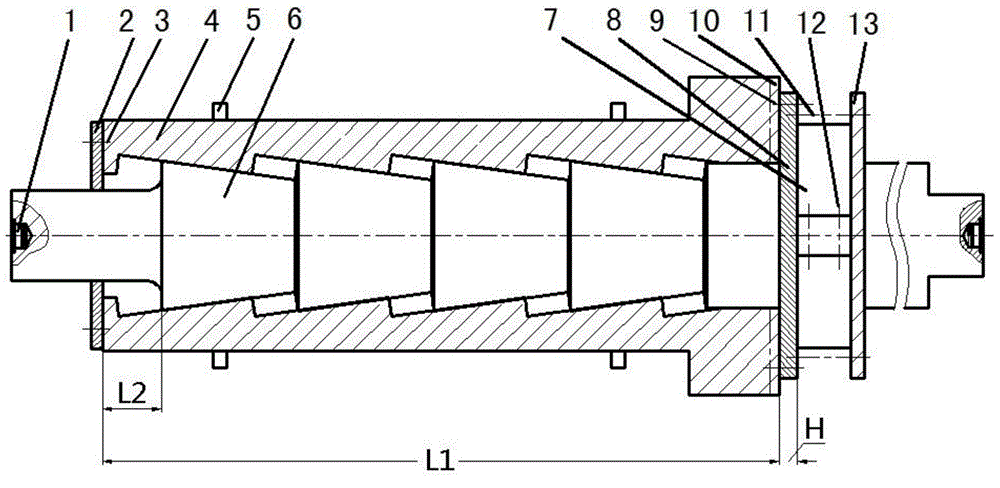

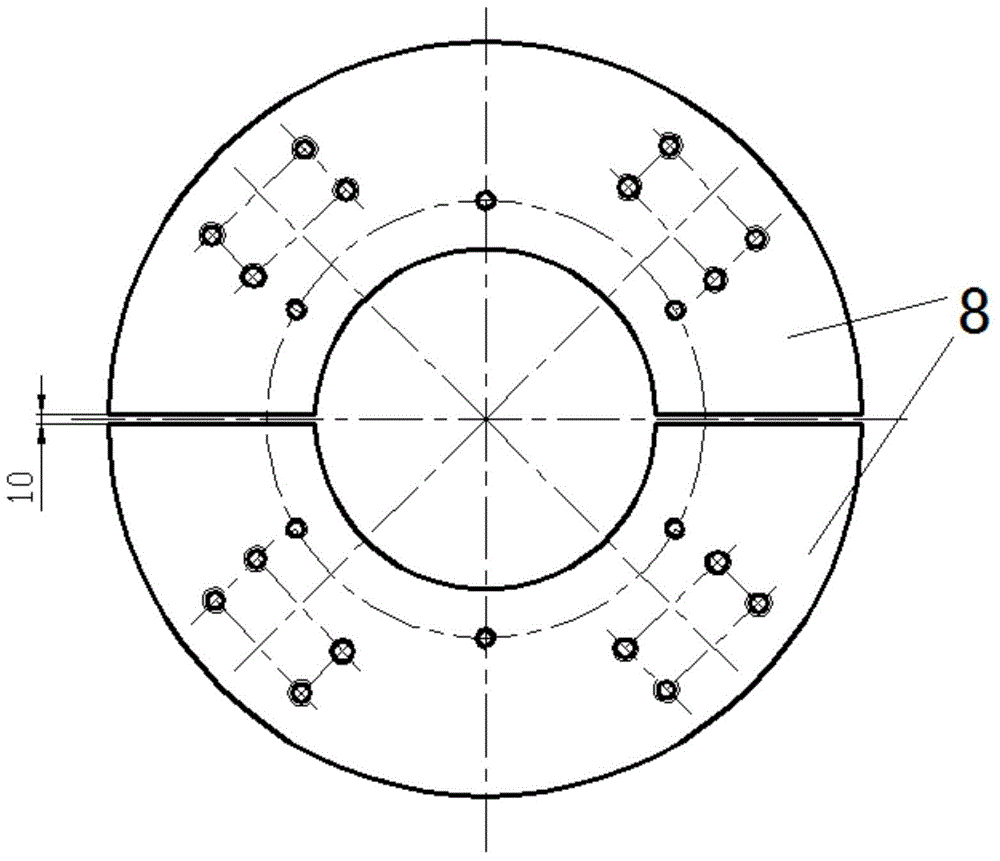

[0023] Such as figure 1 and figure 2 As shown, the structure of the split backing plate positioning device that the method of the present invention relies on includes a main shaft 6, an insertion plug 1 is installed in the center holes at both ends of the main shaft 6, and four fan-shaped parts are installed around the main shaft 6. Plate 4, the outer surface of four fan-shaped plates 4 is provided with at least two clamps 5; on the shoulder side of the main shaft 6 pyramids ( figure 1 On the right side) there is a positioning body 7, and a tooling backing plate 10 is respectively arranged in the end face grooves of the four fan-shaped plates 4 facing the positioning body 7, and a tooling backing plate 10 is provided between the tooling backing plate 10 and the inner end surface of the positioning body 7 Backing plate 8, backing plate 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com