Automatic trimming machine for tree shapes

A technology for automatic pruning and tree trimming, which can be applied to equipment for trimming hedges, etc., which can solve the problems of personal injury, high risk, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

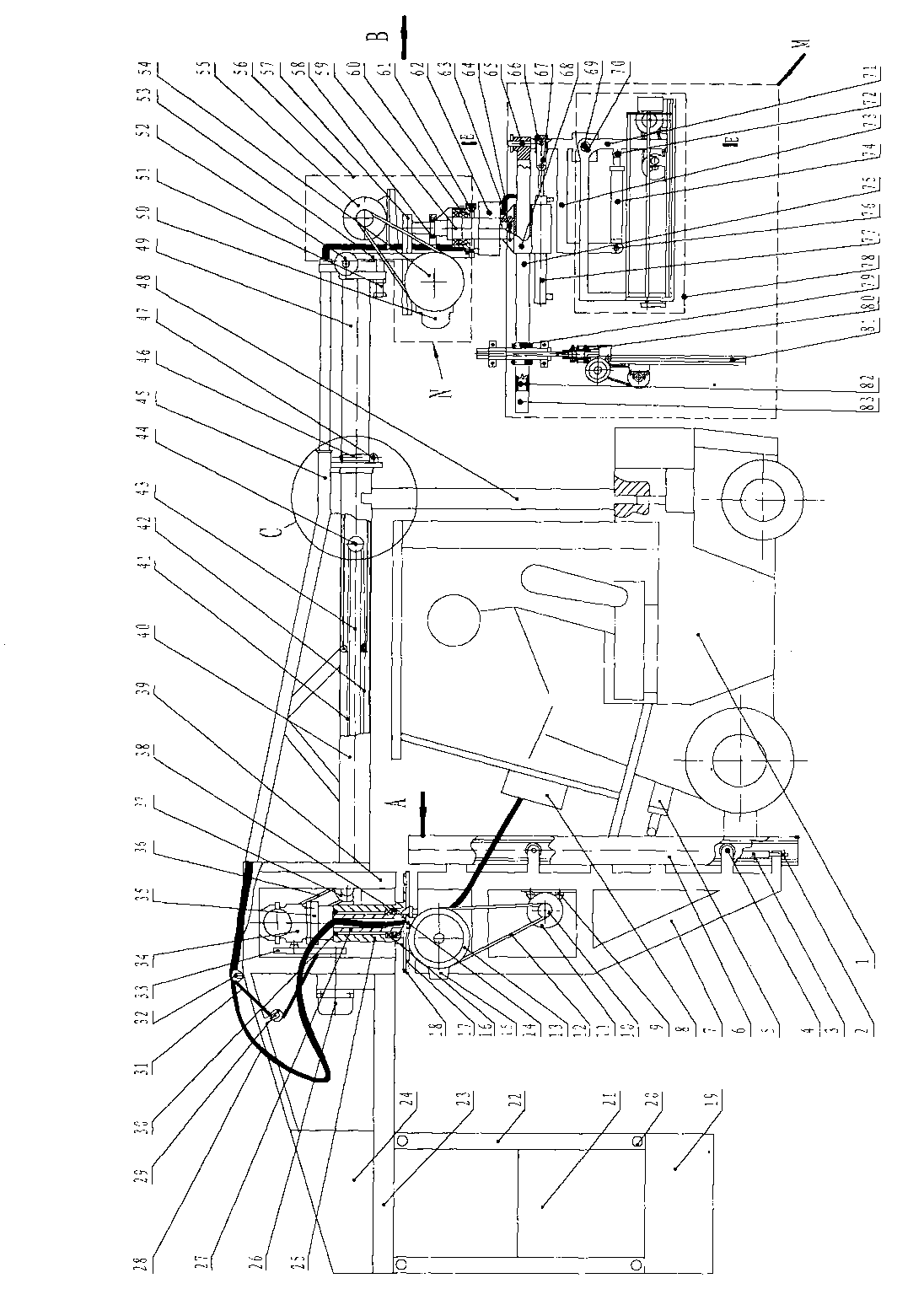

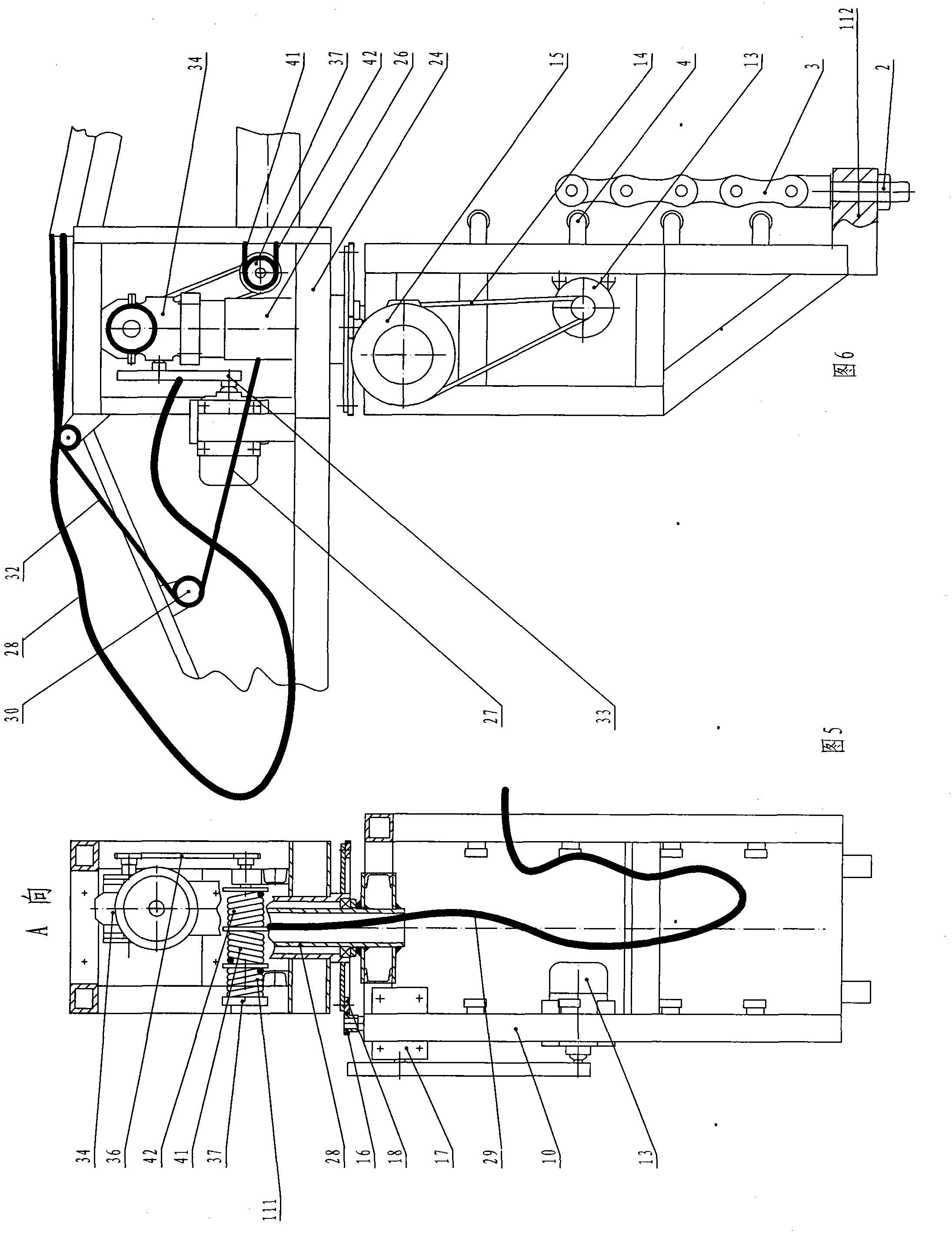

[0034] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , insert the frame (7) into the track groove of the forklift (1), insert the forklift chain bolt (2) on the forklift chain (3) into the corresponding hole of the chain lug (112), and tighten Nut, turret (39) is enclosed within on the frame rotating shaft (27) together with turret sleeve (25), and the one side of turret (39) is equipped with turret balance frame (23), is connected with generator set hanger on it (22), the generator set (21) is connected on the hanger (22), and the opposite side of the turret (39) symmetry is equipped with a boom (40), and the wire rope support bar (43) is sleeved in the boom (40). ) and telescopic arm (49), the head base (53) is hinged in the head turning hinge (52) of the leaking end of the telescopic arm (49), and the vertical shaft rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com