Design method of shafting oscillation filter for permanent magnet direct drive wind turbine

A technology for wind turbine and filter design, applied in the direction of reducing/preventing power oscillation, harmonic reduction device, AC network to reduce harmonic/ripple, etc., can solve problems affecting the safety and reliability of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

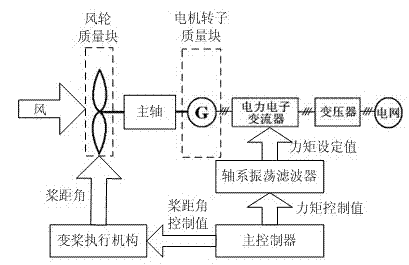

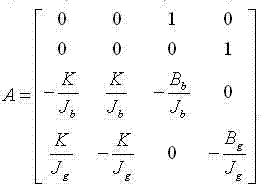

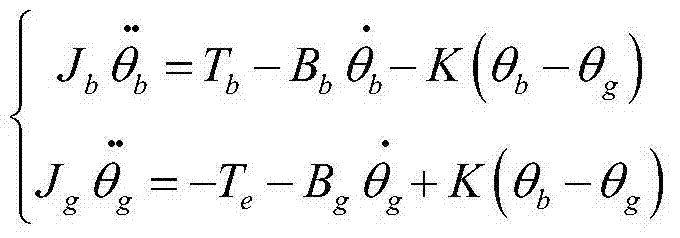

[0017] In step 1, the transmission link of the permanent magnet synchronous wind turbine can be equivalent to two mass links of the wind rotor mass block and the generator rotor mass block, and the model is modeled according to the following formula:

[0018]

[0019] In the formula is the equivalent moment of inertia of the mass block of the wind rotor of the permanent magnet direct drive wind turbine;

[0020] is the rotation angle of the main shaft at the rotor end of the permanent magnet direct drive wind turbine;

[0021] is the aerodynamic torque at the connection between the rotor end and the hub of the permanent magnet direct drive wind turbine;

[0022] is the damping coefficient of the mass block of the wind rotor;

[0023] is the spindle rigidity coefficient;

[0024] is the equivalent moment of inertia of the generator rotor mass block of the permanent magnet direct drive wind turbine;

[0025] is the rotation angle of the main shaft at the gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com