Automatic control system of two-for-one twister

An automatic control and two-for-one twister technology, applied in digital control, electrical program control, spinning machines, etc., can solve the problems of two-for-one twisters with bloated structure, complicated maintenance, lack of diversity and flexibility of two-for-one twisters, etc., and achieve The effect of flexible machine running status, simplified structure and flexible change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

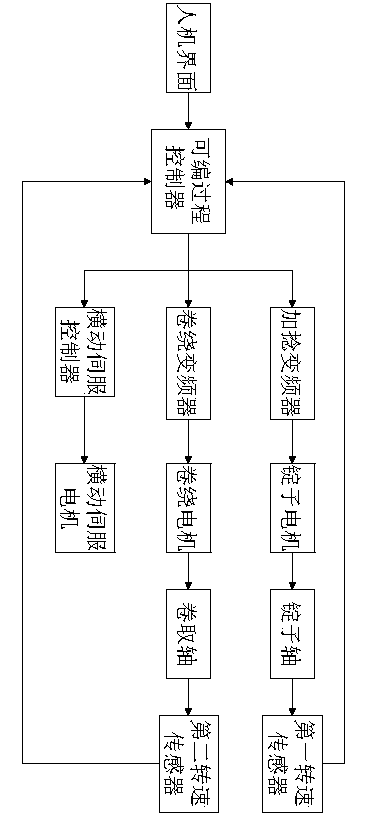

[0014] Such as figure 1 As shown, in an embodiment of the present invention, the programmable process controller data is connected to the twisting frequency converter, the winding frequency converter, the traverse servo, the first rotational speed sensor, the second rotational speed sensor and the man-machine interface, and the twisting The frequency converter, winding frequency converter and traversing servo control the spindle motor, coiling motor and traversing servo motor respectively. The first speed sensor and the second speed sensor are respectively installed on the spindle shaft and the take-up shaft to detect their speed. There is a definite proportional relationship between the motor and the crimping motor, and there is a definite relationship between the crimping motor and the traverse servo motor.

[0015] When the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com