Flaw sagger automatic eliminating and replacing device used in electronic kiln automatic production line

An automatic production line and saggar technology, applied in furnaces, furnace components, charge control, etc., can solve problems such as differences in work responsibilities, troublesome removal of electronic powder materials, and influence on firing efficiency, so as to reduce labor intensity and eliminate injuries. and workers' limbs, and the effect of saving labor resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

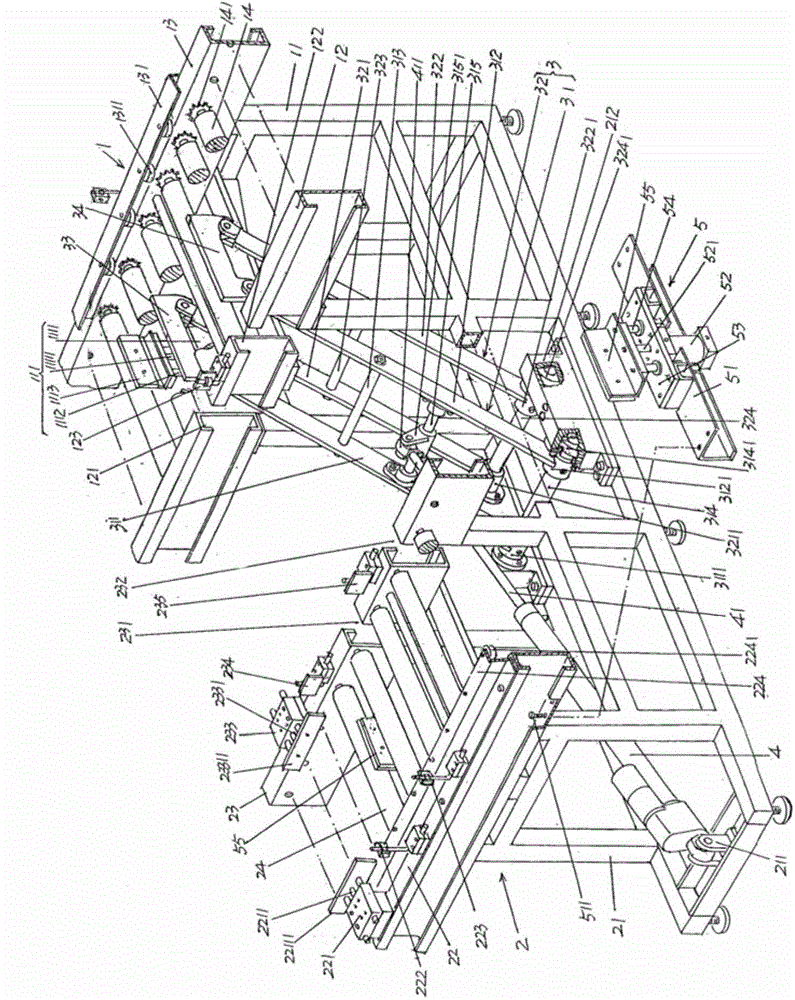

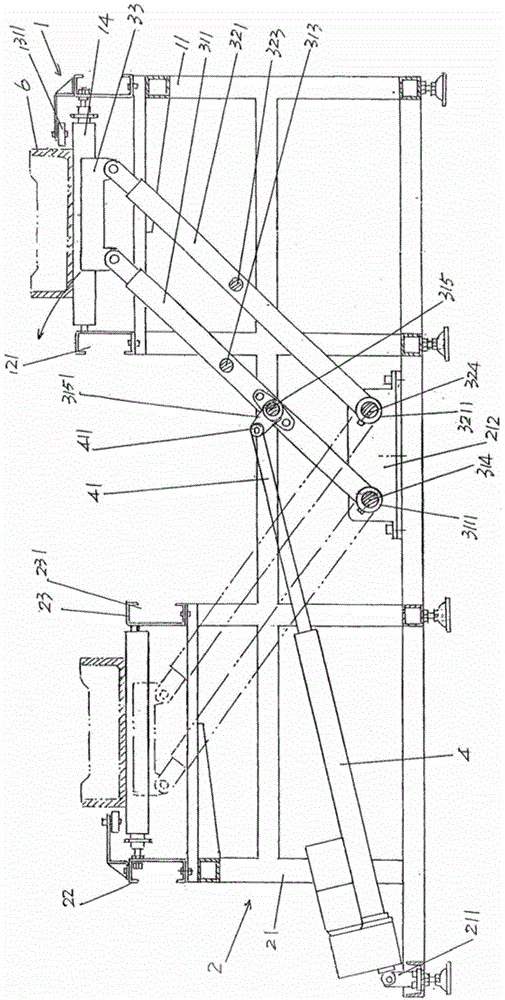

[0023] Please see figure 1 , provides a sagger automatic conveying mechanism 1 belonging to the structural system of the electronic kiln automatic production line, the sagger automatic conveying mechanism 1 includes an automatic sagger conveying frame 11, and the sagger automatic conveying frame 11 is in use The bottom is arranged between the furnace entrance and the furnace outlet of the electronic kiln; a first sagger conveying roller pivot support beam 12 and a second sagger convey roller pivot support beam 13, the first and second sagger convey Roller pivoting support beams 12, 13 are arranged along the length direction of the sagger automatic conveying frame 11 in a state parallel to each other, and are positioned at the top of the sagger automatic conveying frame 11; a group of sagger conveying rollers 14, the group The sagger conveying roller 14 is rotatably supported between the first and second sagger conveying roller pivot support beams 12 and 13 in a spaced state. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com