Naipu lin-jun overturning valve

A flip valve, Naipu technology, applied in multi-way valves, valve devices, liquid fuel engines, etc., can solve the problems of lax closure, high cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

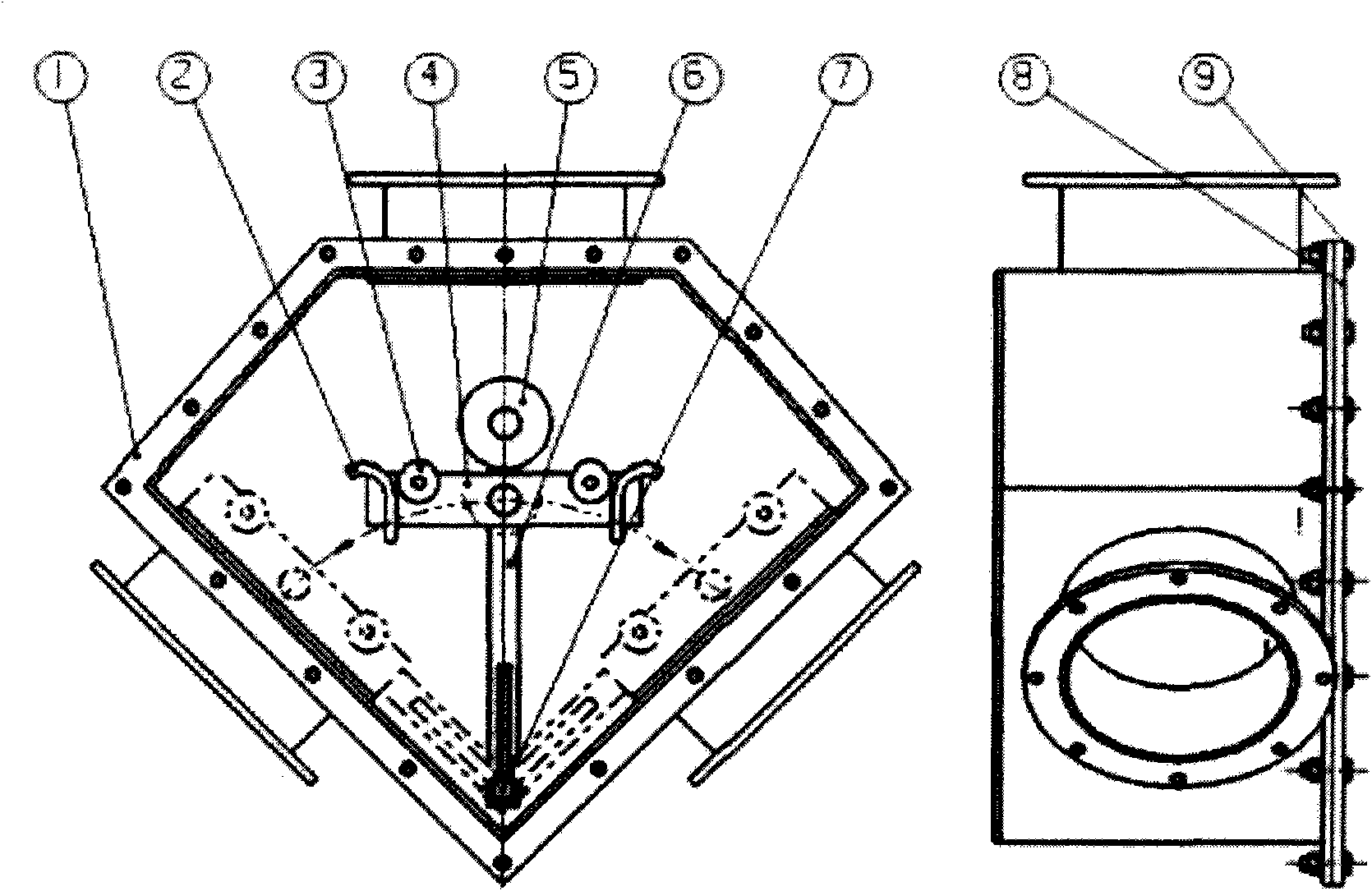

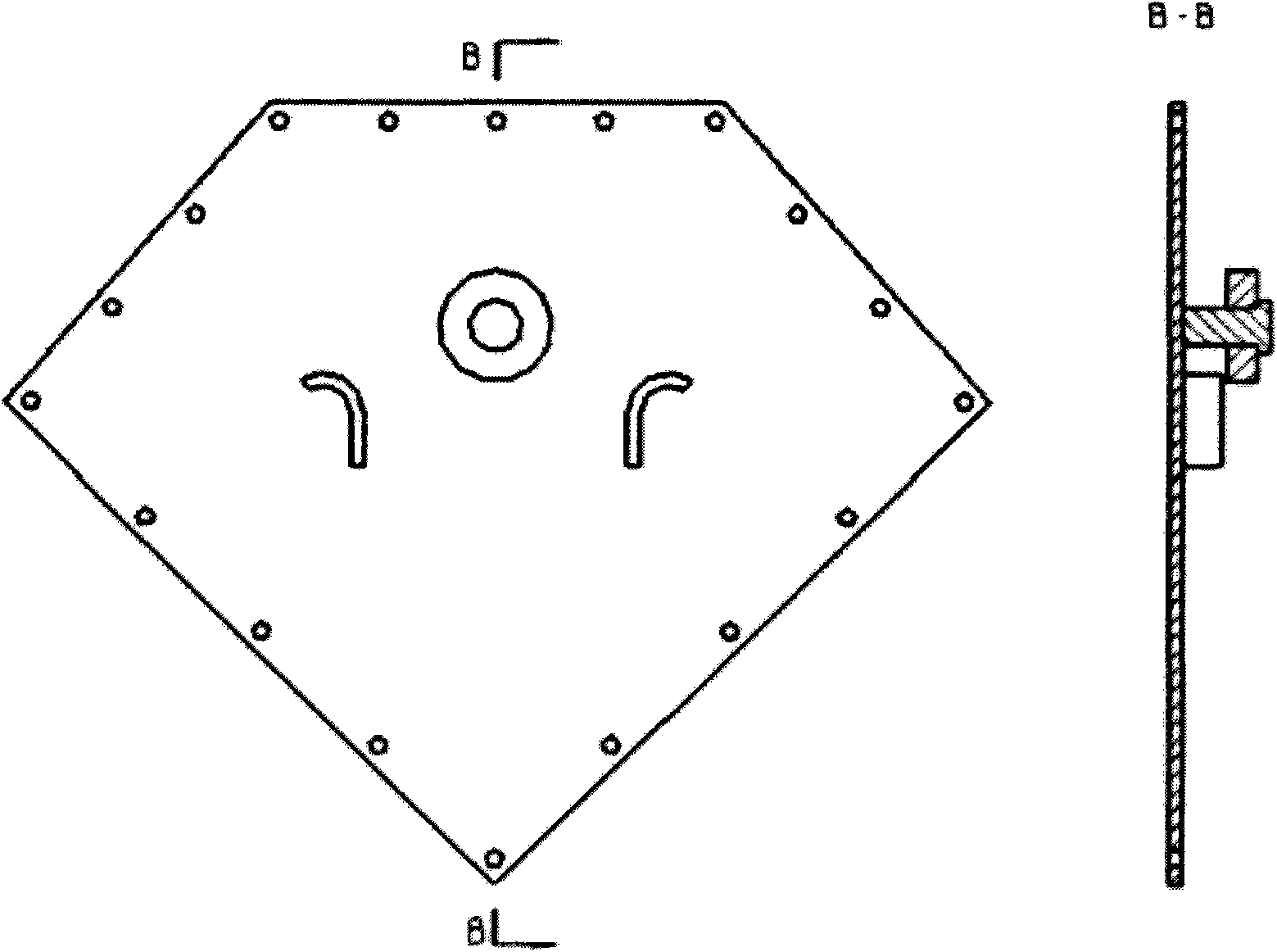

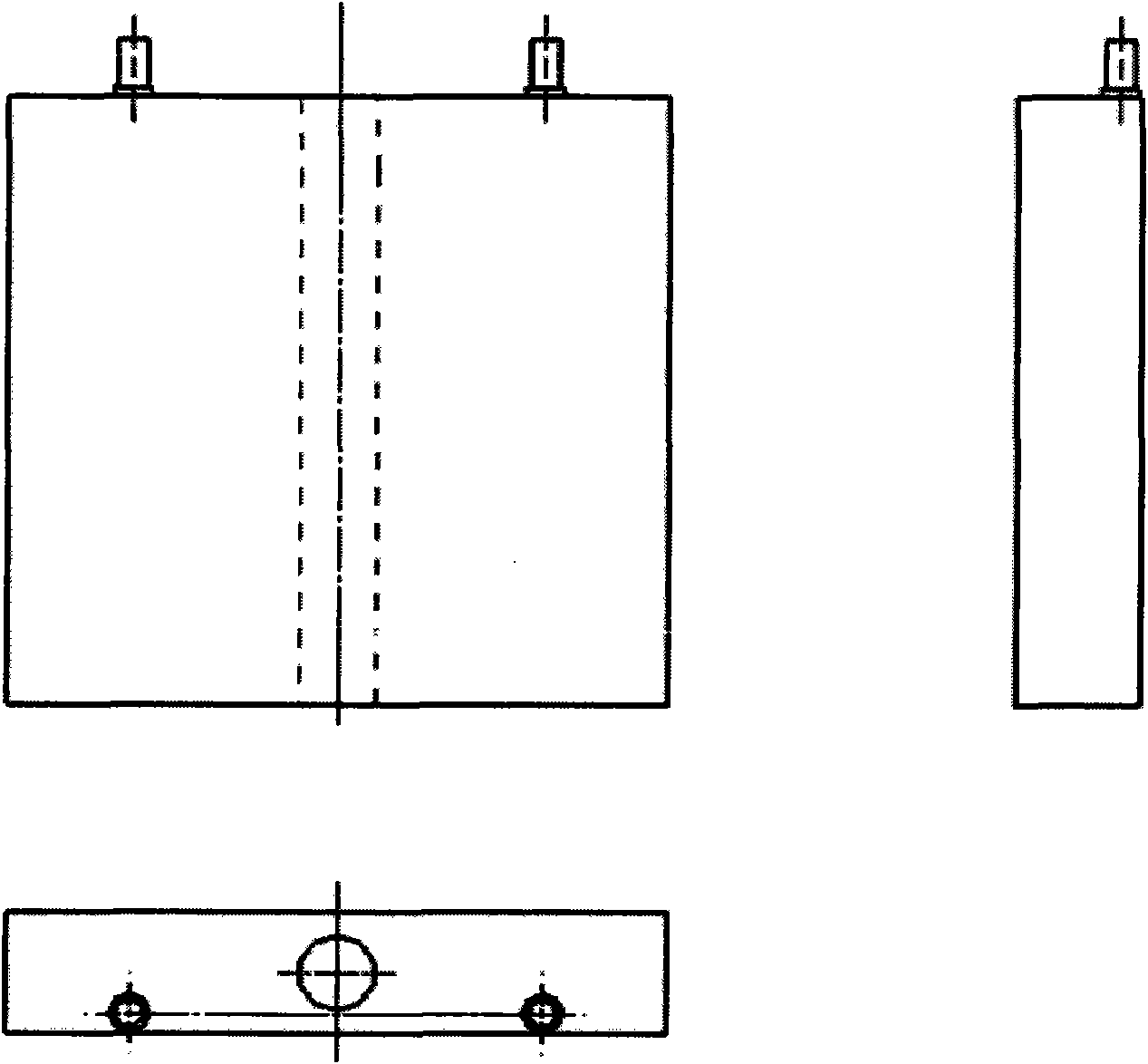

[0012] The assembly relationship of the above-mentioned Naipurin overturn valve is the embodiment of the present invention, and its production and assembly relationship is: one end of the swing arm rotary shaft 7 is fixed on the valve housing 1, the swing arm 6 is sleeved on the swing arm rotary shaft 7, and the swing arm rotary shaft 7 The other end is provided with a valve 4 rotary shaft, the valve 4 is sleeved on the rotary shaft, the upper end of the valve 4 is symmetrically offset by two guide wheels 3 on both sides, the guide rail 2 and the turning wheel 5 are connected to the cover plate 8, and the cover plate 8 passes through The connecting bolt 9 is integrally connected with the valve casing 1 . All surfaces in contact with the slurry are covered with wear-resistant materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com