Gas mixer

A gas mixer and air intake pipe technology, which is applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of uneven mixing of incoming gas, achieve fast and full mixing, stable and reliable quality, and improve growth. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

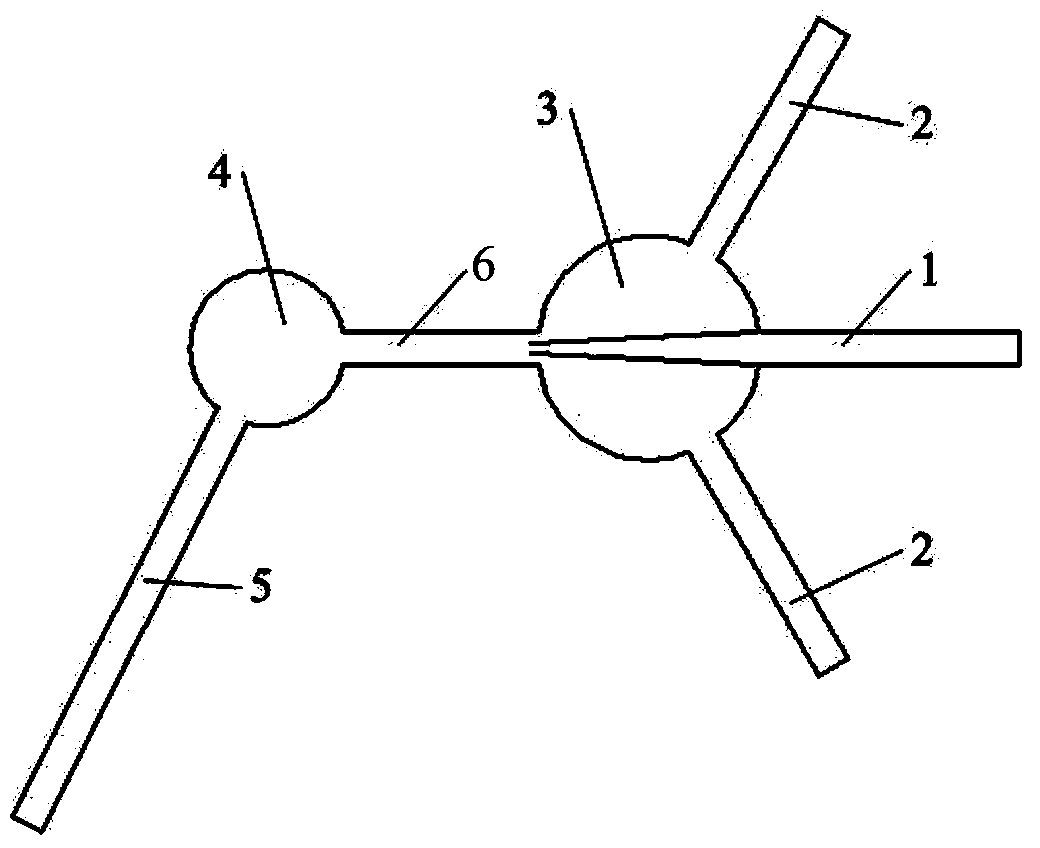

[0021] Such as figure 1 As shown, the gas mixer includes a first hollow sphere 3 and a second hollow sphere 4 , and the diameter ratio of the first hollow sphere 3 to the second hollow sphere 4 is 1.2:1. One side of the first hollow ball 3 is provided with a first air intake pipe 1 and two second air intake pipes 2, wherein the end section of the first air intake pipe 1 stretches into the inside of the first hollow ball 3, and the first air intake pipe 1 The end of the air intake pipe 1 is at the air outlet of the first hollow ball 3 . The end section of the first air intake pipe 1 is preferably contracted, such as a tapered pipe, which helps to further improve the flow rate of the gas in the air intake pipe when it goes out, and between the two second air intake pipes 2 and the first air intake pipe 1 respectively Maintain a 60-degree angle. The air outlet of the first hollow ball 3 is connected with the air inlet of the second hollow ball 4 by the pipeline 6, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com