Zinc-nickel infiltrated layer anti-corrosion treatment tooling for rail fasteners

A technology of anti-corrosion treatment and elastic strips, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve problems such as affecting the production efficiency of zinc-nickel infiltration layer, spending a lot of time manual separation, and reducing the loading capacity. To achieve the effect of reducing the workload of manual separation, expanding the scope of product adaptation, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

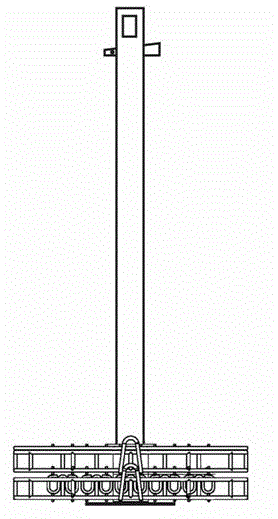

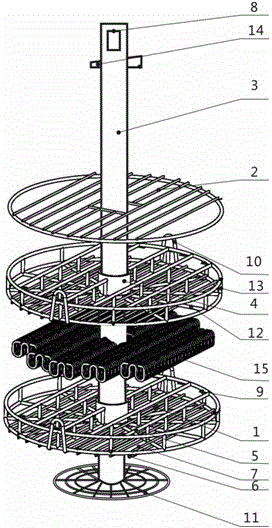

[0020] like figure 1 , figure 2 As shown, the zinc-nickel infiltrated layer anti-corrosion treatment tooling for rail fastener springs of the present invention includes a material basket 1, a cover net 2 and a suspension shaft 3, and the material basket 1 is cylindrical in shape with one end open and one end with a bottom. The column tube core 4 for the hanging shaft to hang is fixed at the center of the material basket 1, the column tube core 4 is flush with the bottom of the material basket 1, and the upper part of the column tube core 4 is higher than the material basket 1. In actual design, the upper part of the column tube core 4 is higher than the material Basket 1 is 15cm higher. In the material basket 1 there are evenly distributed a number of elastic support ribs 5 parallel to each other for hanging the elastic bars, and the surfaces formed by all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com