Method for preparing darunavir amorphous

A technology for darunavir and amorphous substances, which is applied in the field of preparing darunavir amorphous substances, can solve the problems of high temperature, high cost, easy generation of impurities, etc., and achieves simple preparation method, low production cost, and high stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Preparation method of amorphous darunavir

[0055] The invention provides a preparation method of amorphous darunavir, comprising the steps of:

[0056] (1) dissolving darunavir or its solvate in the first solvent described in the present invention to form a first solution containing darunavir;

[0057] Wherein, the solvate may include: darunavir ethanolate, hydrate, methanolate, acetonate, methylene chloride, ethyl acetate, 1-methoxy-2 - propanolate, anisole, tetrahydrofuryl, isopropanolate, mesylate, etc.; preferably methanolate, ethanolate, hydrate, or combinations thereof.

[0058] In another preferred example, the ratio (g / mL) of the mass (W) of darunavir or its solvate to the volume (V) of the first solvent (g / mL) is 1:2-50, preferably 1:5 -15.

[0059] In another preferred example, the dissolution is completed at a temperature of 20-50°C, preferably 25-40°C.

[0060] (2) Mix the first solution containing darunavir with the second solvent of the present invent...

Embodiment 1

[0077] Example 1 Preparation of amorphous darunavir

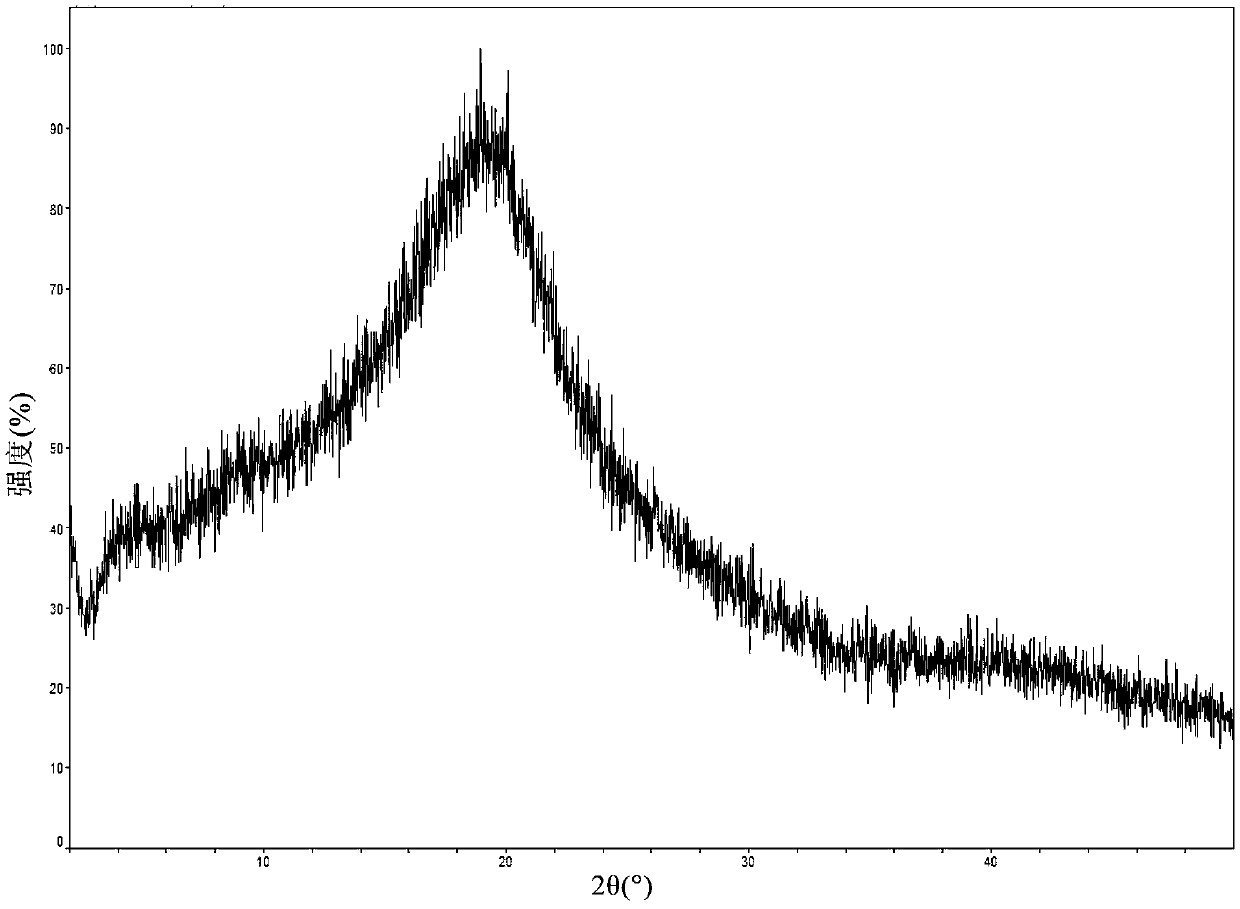

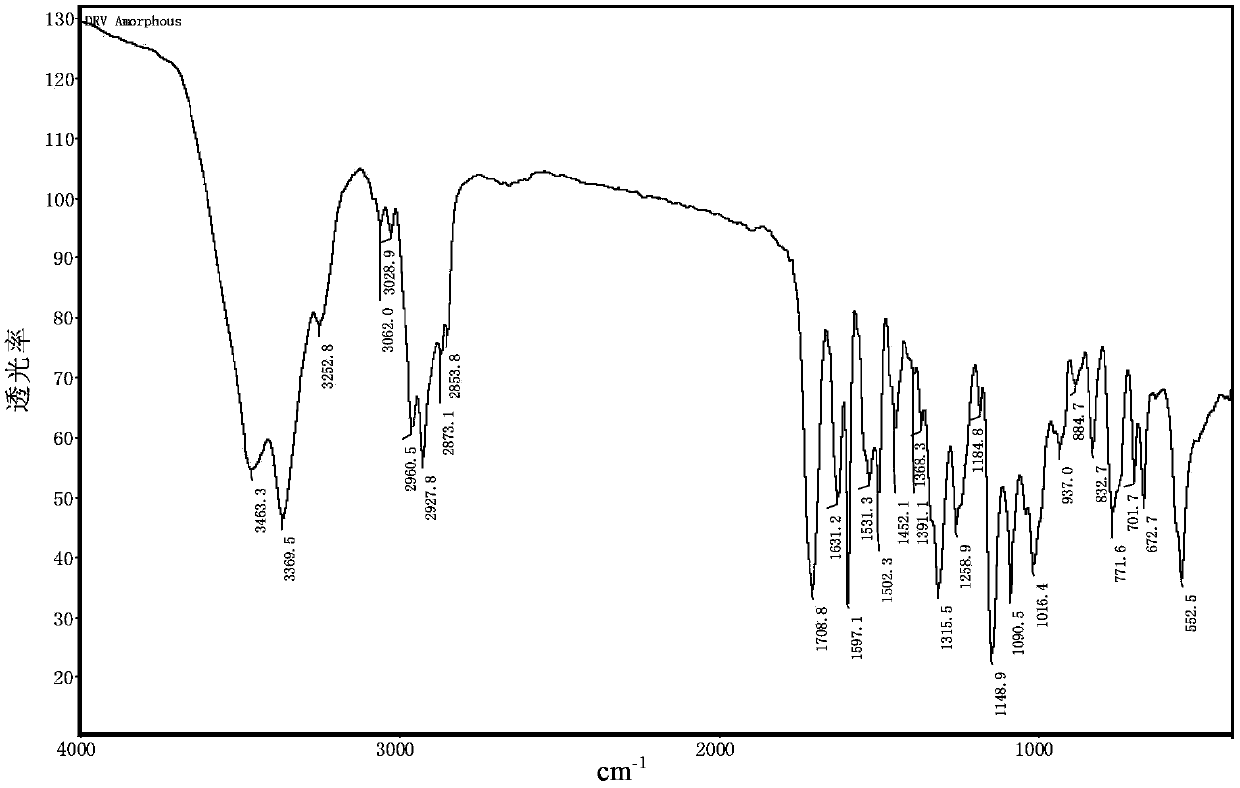

[0078] At 35°C, dissolve 10g of darunavir ethanolate in 20mL of methanol, and add the resulting solution dropwise into 300mL of cold water (water temperature is 0-5°C) under stirring, and stir for 1-3 hours after the drop is complete . Filtration, the filter cake was washed with about 50mL of water, and dried to obtain 9.5g of white solid, which was detected as amorphous darunavir, and its XRPD pattern was as follows: figure 1 As shown, the IR diagram is as figure 2 As shown, the DSC diagram is shown in image 3 shown.

Embodiment 2

[0079] Example 2 Preparation of amorphous darunavir

[0080] At room temperature, dissolve 200g of darunavir methanolate in a mixed solvent containing 1000ml of methanol and 1000ml of ethanol, and add the resulting solution dropwise to 4L of cold water (water temperature is 5-10°C) under stirring. Stir for 1-2 hours. After filtering, the filter cake was washed with about 200 mL of water and dried to obtain 192 g of white solid. After testing, it is amorphous darunavir, and its XRPD pattern, FTIR pattern, and DSC pattern are basically consistent with those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com