Valve needle guide sleeve

A technology of guide sleeve and valve needle, which is applied in the field of valve needle guide sleeve and valve needle guide sleeve, which can solve the problems of guide sleeve glue seepage, small deformation, guide sleeve wear, etc., to avoid glue seepage , Reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

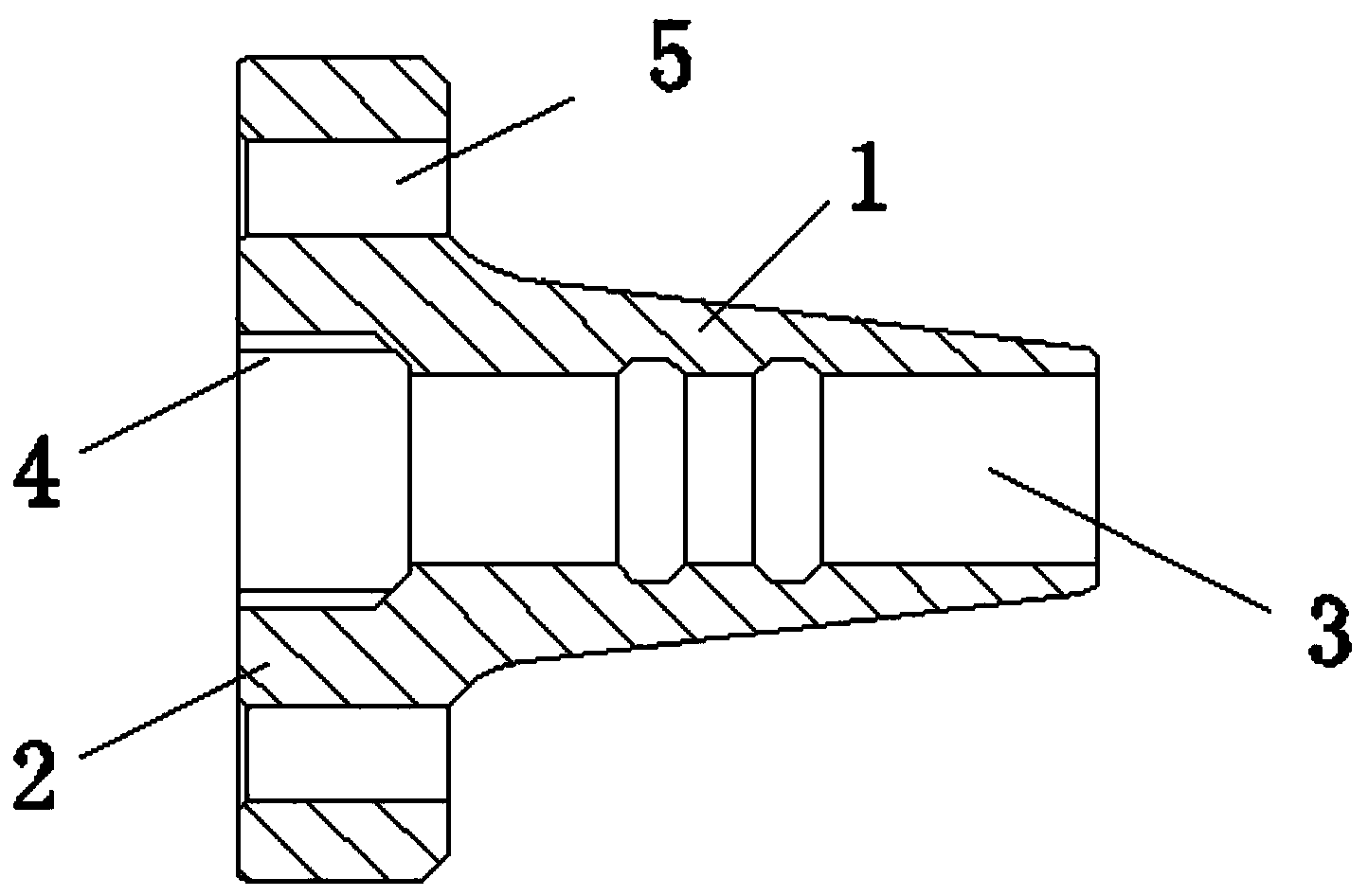

[0012] Such as figure 1 As shown, a valve needle guide sleeve according to the present invention includes a sleeve 1 and a fixing seat 2; the sleeve 1 is provided with a valve needle matching hole 3; Rear end; the fixing seat 2 is provided with a hoisting screw hole 4 and a plurality of fixing holes 5; On the same straight line; the inner diameter of the hoisting screw hole 4 is larger than the diameter of the valve pin matching hole 3 .

[0013] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0014] The valve needle diversion sleeve of the present invention is divided into two parts as a sleeve 1 and a fixed seat 2 as a whole. The length of the sleeve 1 can ensure the matching requirements of the valve needle matching hole 3 and the valve needle, reduce wear and avoid glue seepage; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com