Large-stroke high-precision Z-axis worktable with novel structure

A workbench and large-stroke technology, applied in the direction of manufacturing tools, machine tables/supports, large fixed members, etc., can solve problems such as difficult to achieve gravity balance, complex structure, lack of sensor monitoring, etc., achieve real-time guarantee of state adjustment, reduce A The effect of Baye error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

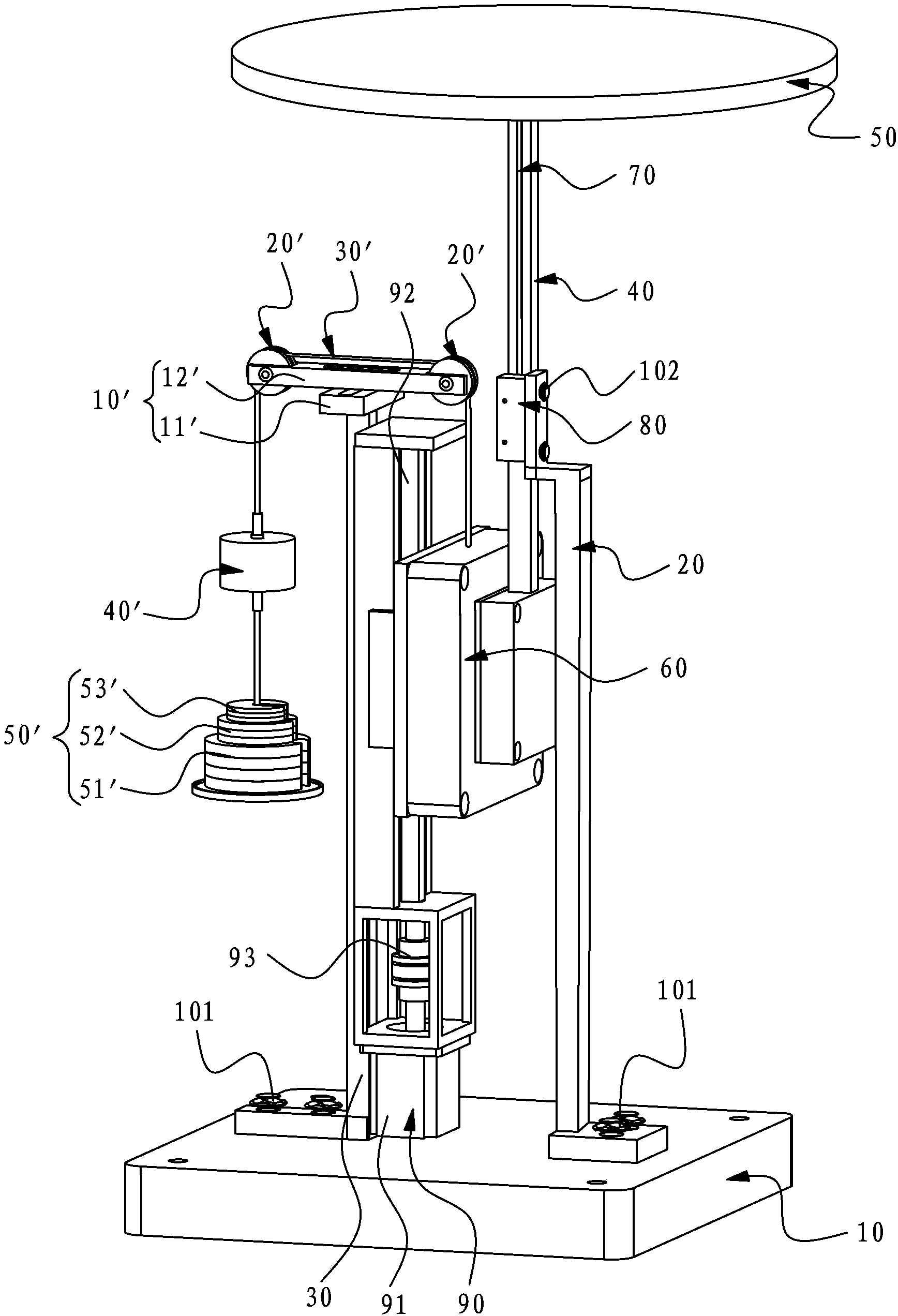

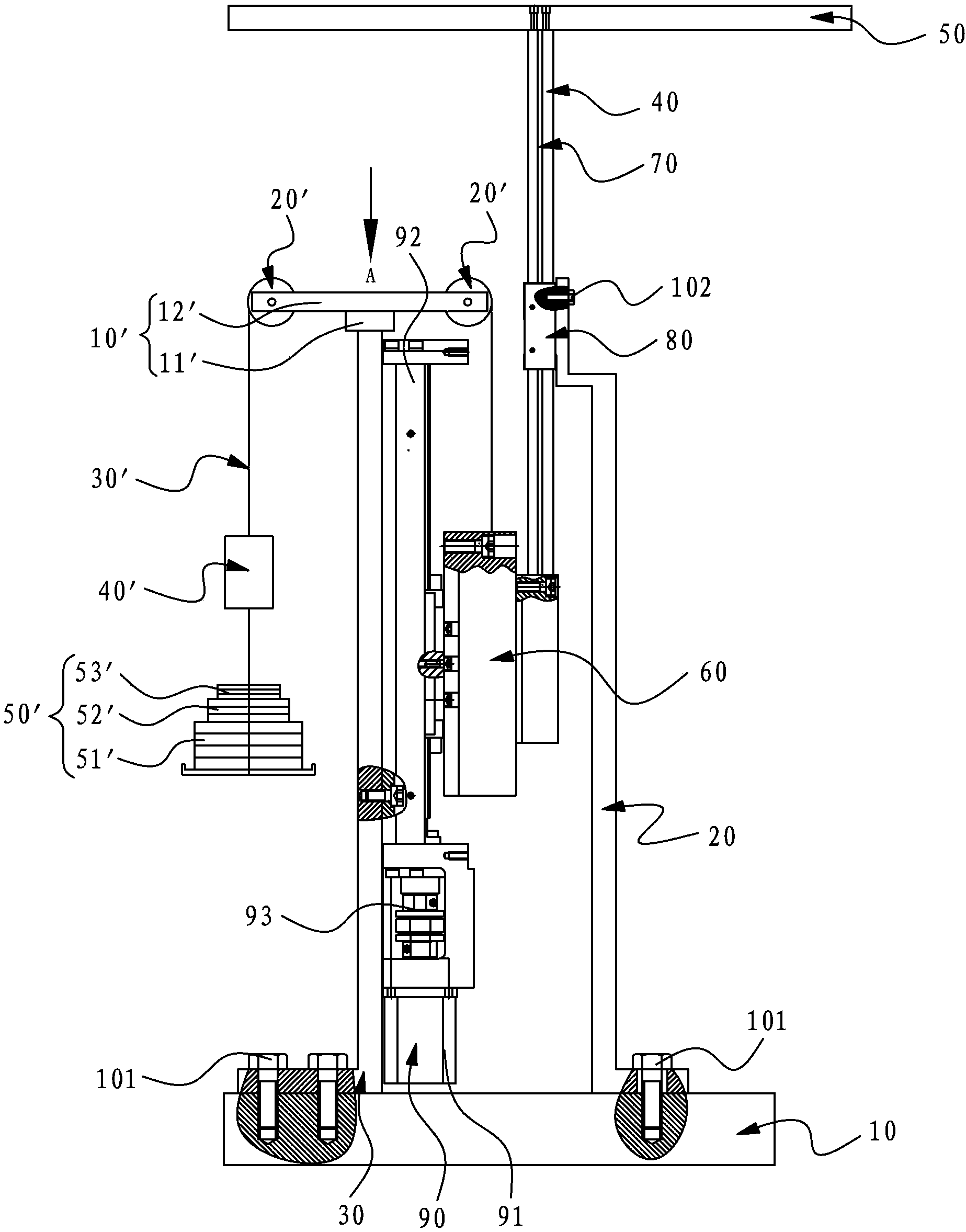

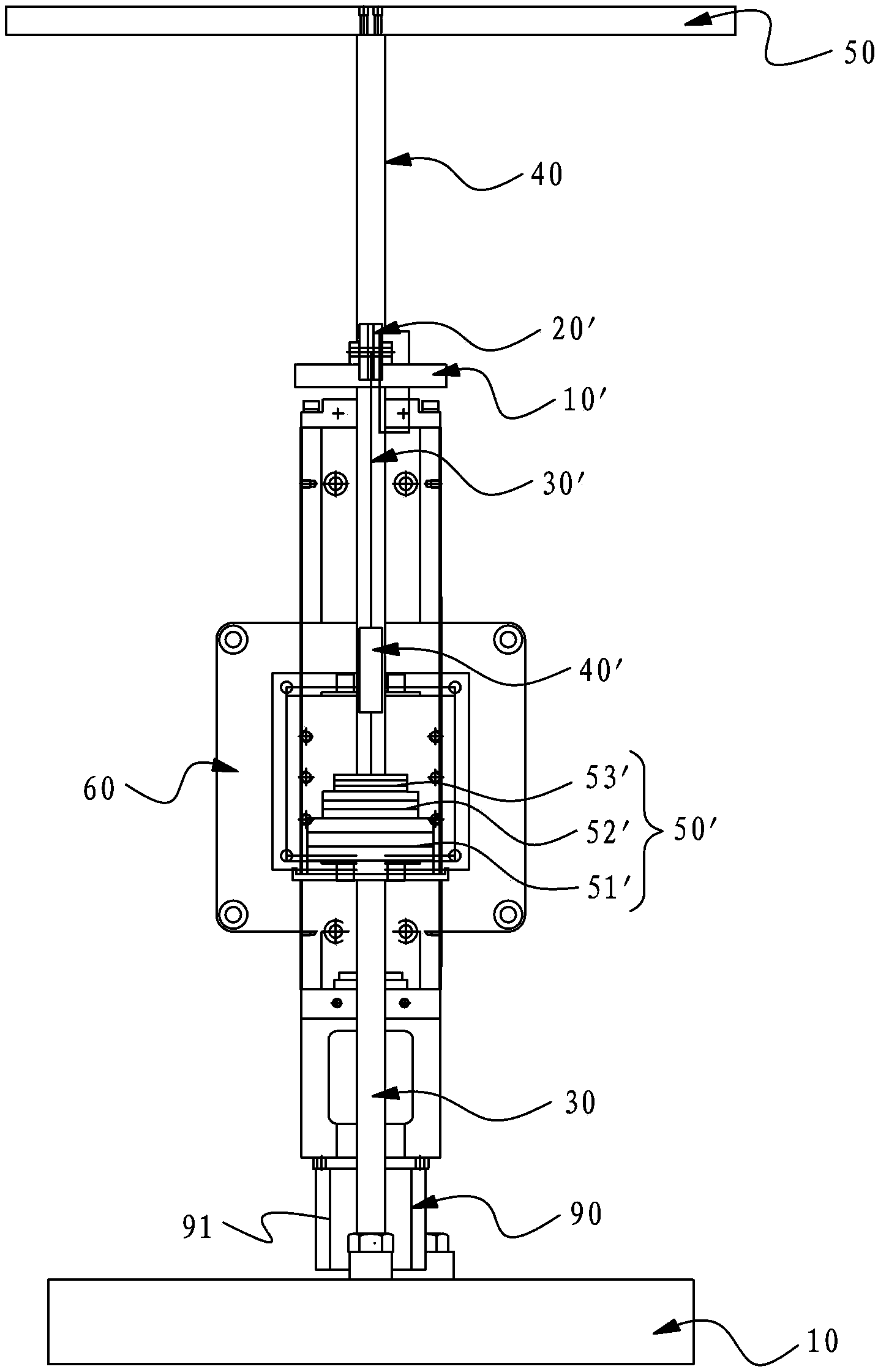

[0039] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a base 10 , a first support 20 , a second support 30 , a movable support rod 40 , a workbench 50 and a precision movable positioning platform 60 .

[0040] Wherein, the first bracket 20 and the second bracket 30 are all arranged on the base 10; in this embodiment, the first bracket 20 and the second bracket 30 are both L-shaped brackets, and the first bracket 20 and the second bracket 30 are all fixed on the base 10 by screws 101, not limited thereto.

[0041] The movable support rod 40 extends vertically, and the movable support rod 40 can be arranged on the first support 20 up and down. The movable support rod 40 is fixed with a vertically extending grating scale 70. There is a grating reading head 80 , which is fixed on the first bracket 20 by slotted flat end set screws 102 .

[0042] The workbench 50 is fixed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com