Double-head milling machine

A double-head milling machine and bed technology, applied in milling machine equipment, milling machine equipment details, clamping and other directions, can solve problems such as low efficiency, inability to guarantee the perpendicularity and parallelism of both ends, and achieve high safety, easy adjustment, The effect of high machine precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

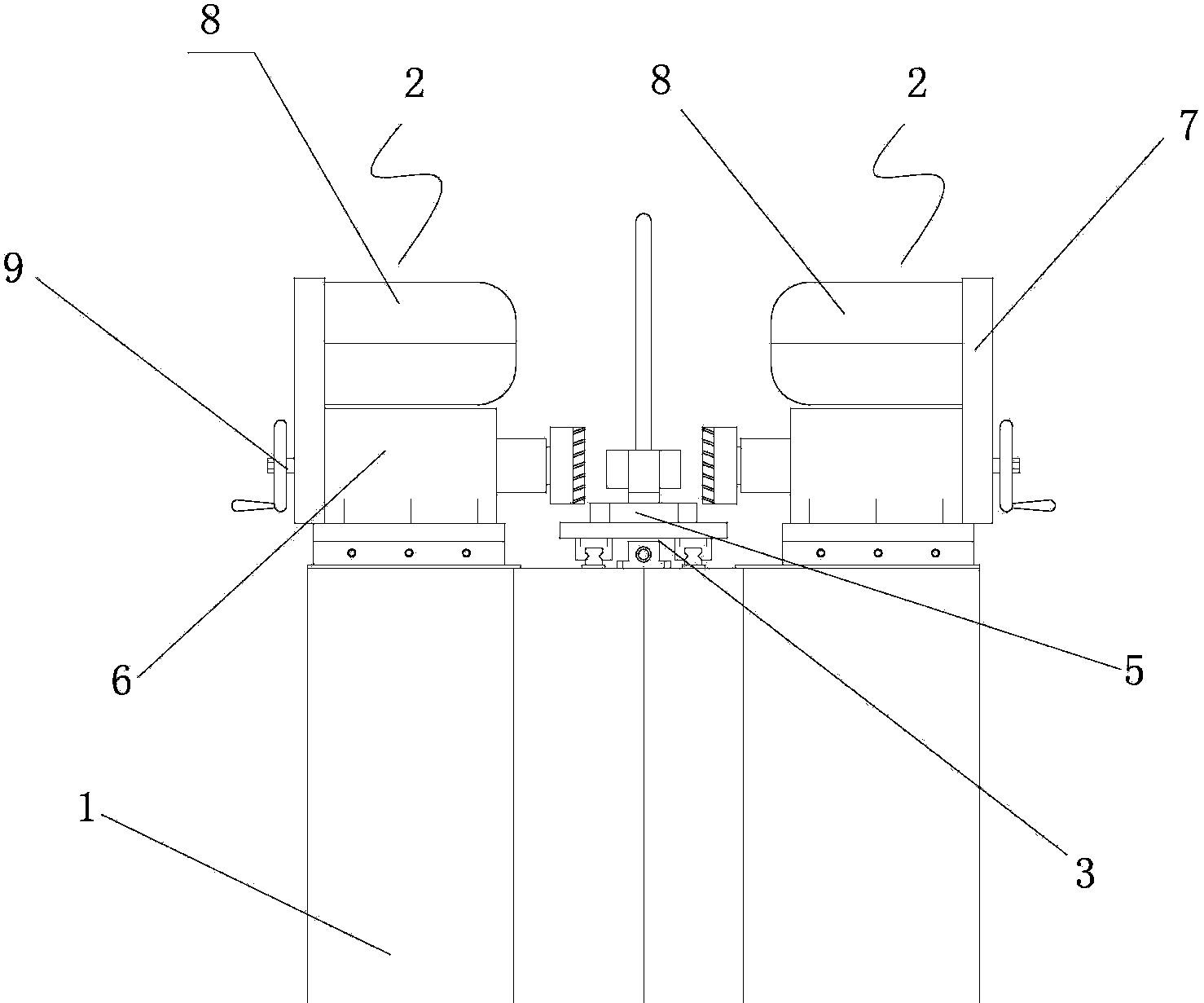

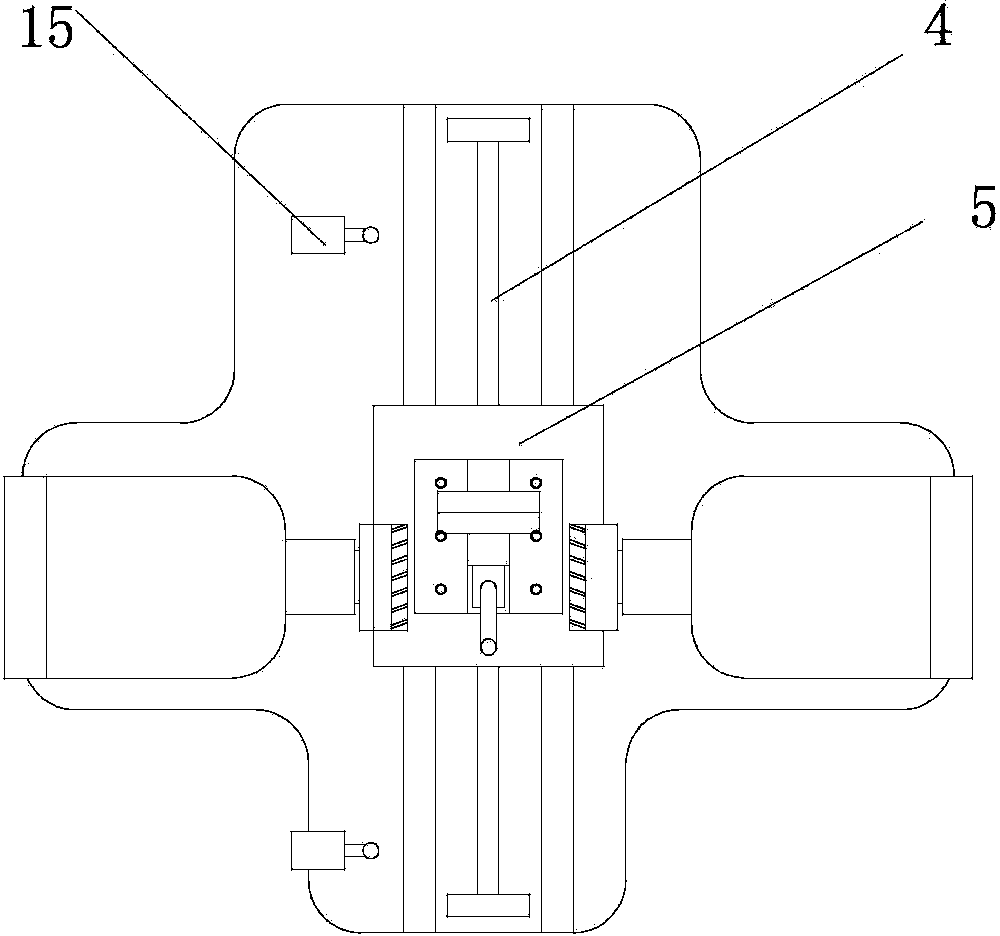

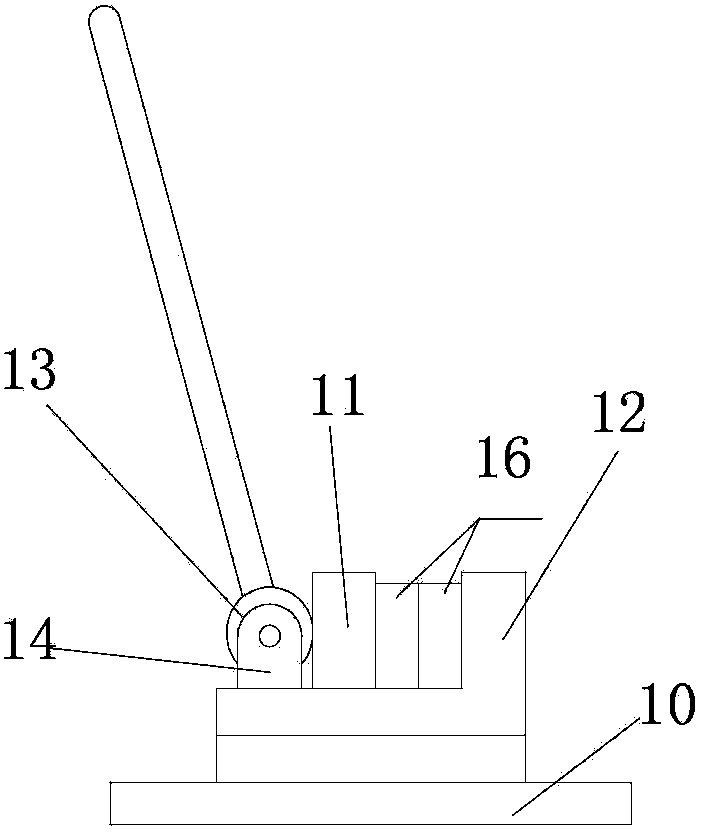

[0013] Below in conjunction with the preferred embodiments, the specific implementation methods provided according to the present invention are described in detail as follows: See the accompanying drawings for details, a double-head milling machine, including a bed 1, a power head 2, a transmission mechanism and a fixture, the bed The left and right power heads are fixedly connected to the bed surface, and the left power head and the right power head are arranged oppositely, and their center lines are on the same axis, and a transmission mechanism 3 is fixedly connected to the bed table at a position perpendicular to the center line of the left and right power heads. The transmission mechanism is composed of a ball screw 4 and a guide rail slider 5, and a fixture is fixedly connected to the guide rail slider. The power head is provided with a spindle box 6 and is connected with a motor 8 through a synchronous pulley 7 , and the power head is provided with an axial feed mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com