Oscillating Saw Head Assembly for Orthopedic Detachable Saw Blade Assembly

A detachable, saw blade technology, applied in the field of medical equipment, can solve the problems of non-disassembly, wear debris, affecting the surgical effect, etc., and achieve the effect of ensuring the matching accuracy and strength, reducing the use cost, and ensuring the surgical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

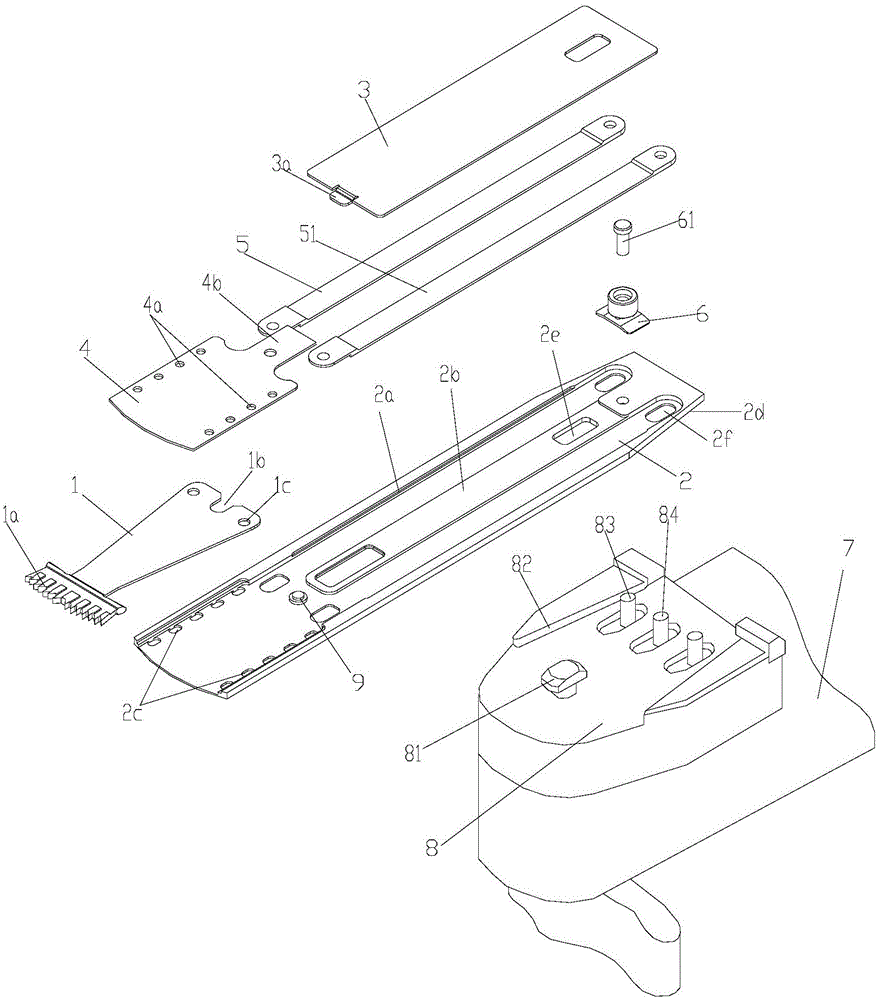

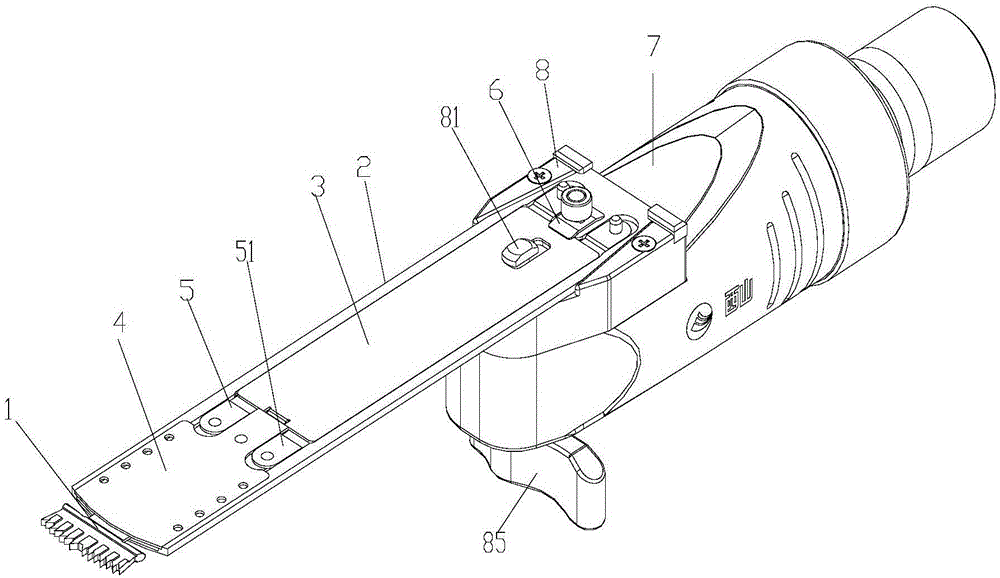

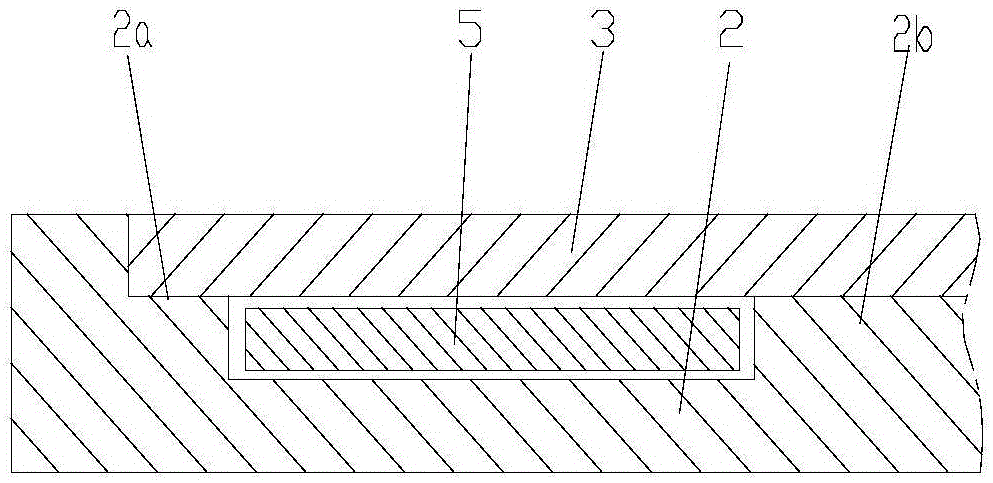

[0021] figure 1 It is the structural explosion diagram of the present invention, figure 2 It is a structural diagram of the present invention, image 3 It is a schematic diagram of the cooperation between the cover plate and the base plate, as shown in the figure: the oscillating saw head assembly of the orthopedic detachable saw blade assembly in this embodiment includes the main machine joint 7 and the saw blade assembly installed on the main machine joint 7. The saw blade assembly includes a saw blade 1, a transmission part and a sheath for installing the saw blade 1 and the transmission part, at least part of the sheath is a detachable structure; at least part of the sheath and all moving parts are a detachable structure It means that the sheath body can be disassembled as a whole, or part of it can be disassembled to achieve the purpose of disassembly and cleaning; the detachable connection method is mainly to facilitate cleaning and ensure installation accuracy.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com