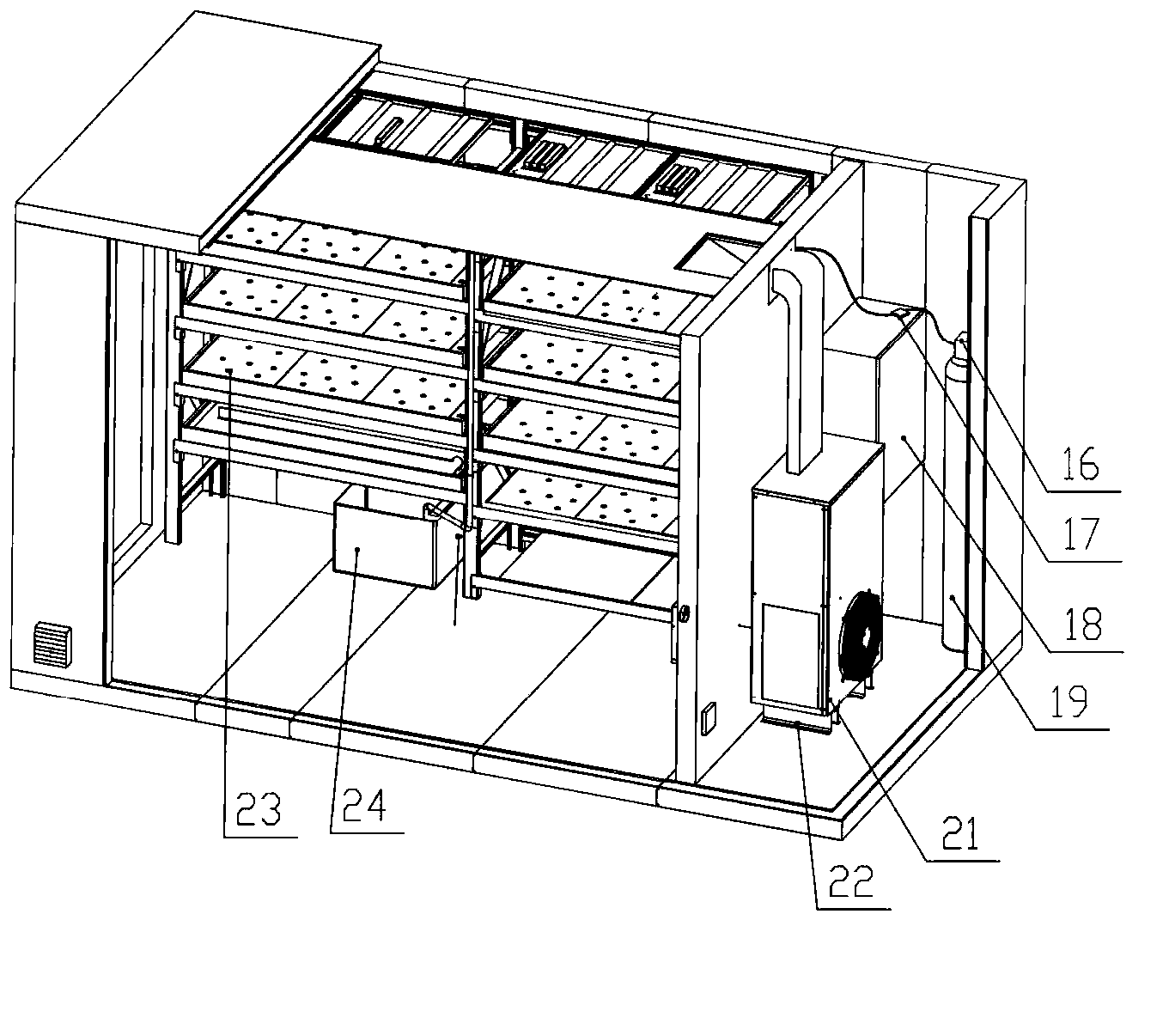

Plant growing box control system and control method thereof

A plant growth box and control system technology, applied in the plant growth box control system and its control field, can solve the problems that the temperature/humidity cannot be uniformly controlled, and the plant growth box lacks a comprehensive control method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

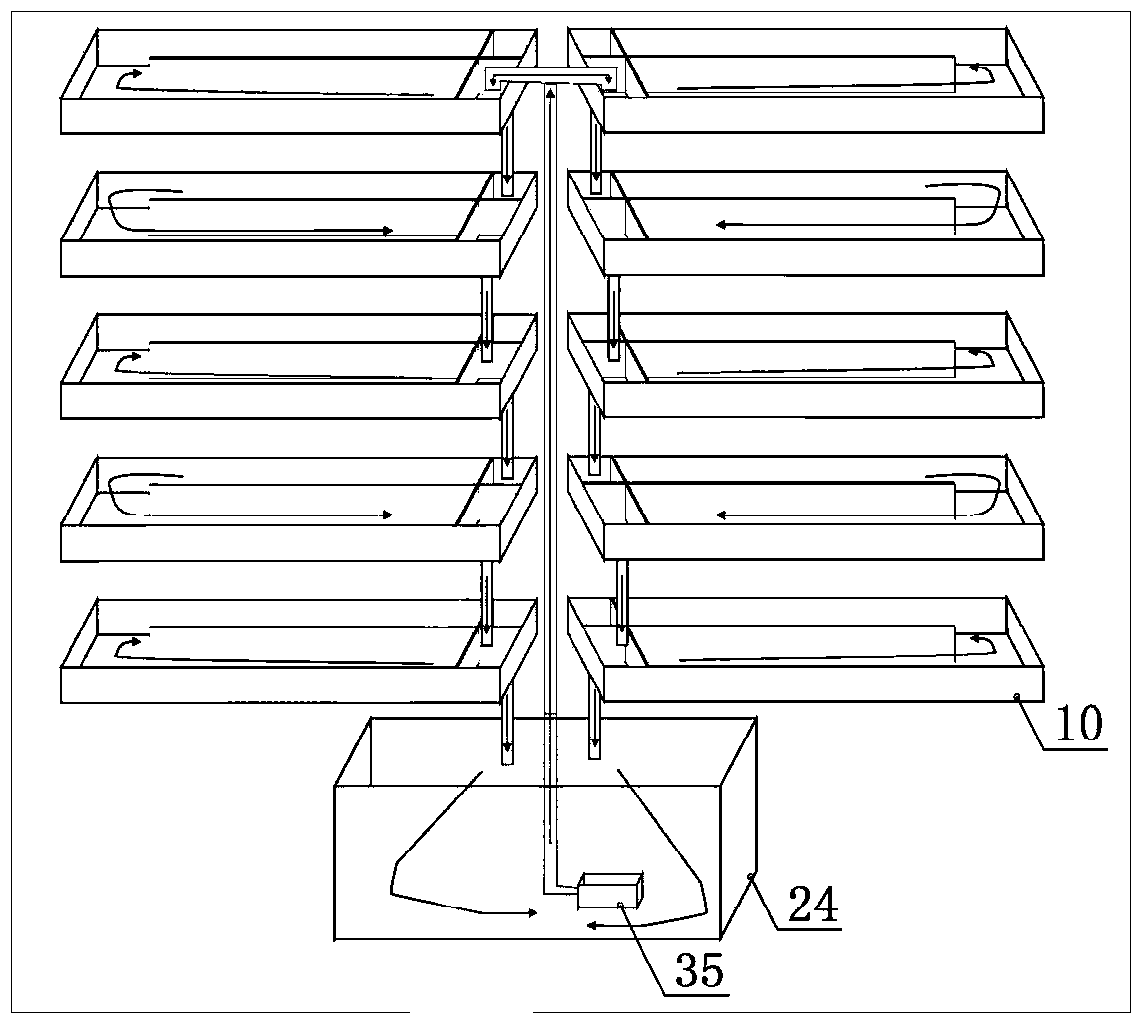

[0070] Taking leafy vegetables as an example, the master control unit sends on / off signals to the LED lights according to the preset light cycle and preset dark cycle to control the LED lights on and off; for example, the preset light cycle is set to 16 hours, and the preset dark cycle is 16 hours. Set to 8 hours.

[0071] When the plants to be cultivated are irradiated by light (that is, in the photoperiod), the master control unit controls the opening and closing of the circulating pump according to the preset circulating pump opening time and the preset circulating pump closing time, and the nutrient solution is sent to the plant when the circulating pump is turned on. to the sink; for example, preset circulation pump on time for 20 minutes and preset circulation pump off time for 10 minutes.

[0072] When the plants to be cultivated are irradiated by light, the master control unit collects the carbon dioxide concentration data of the cultivation room through the carbon dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com