Fuel Injection Control System for Internal Combustion Engine

A fuel injection and control system technology, applied in fuel injection devices, charging systems, engine control, etc., can solve problems such as poor discharge of high-pressure fuel pumps, poor discharge of high-pressure fuel pumps, fuel injection systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

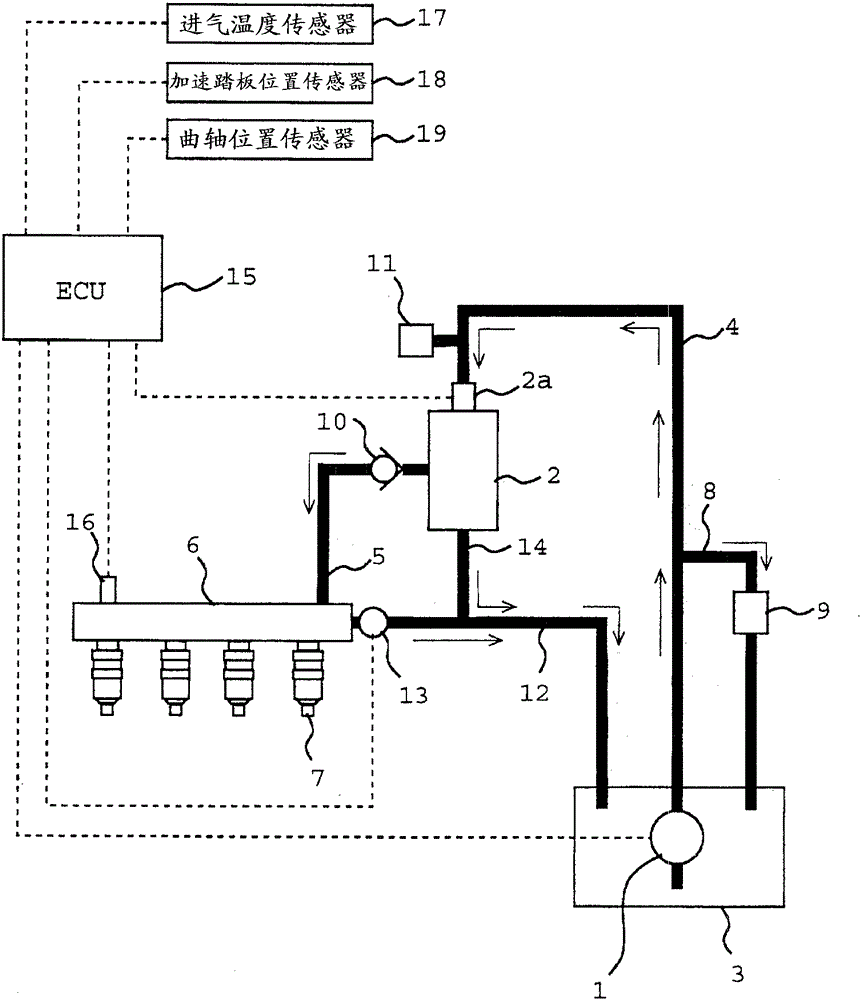

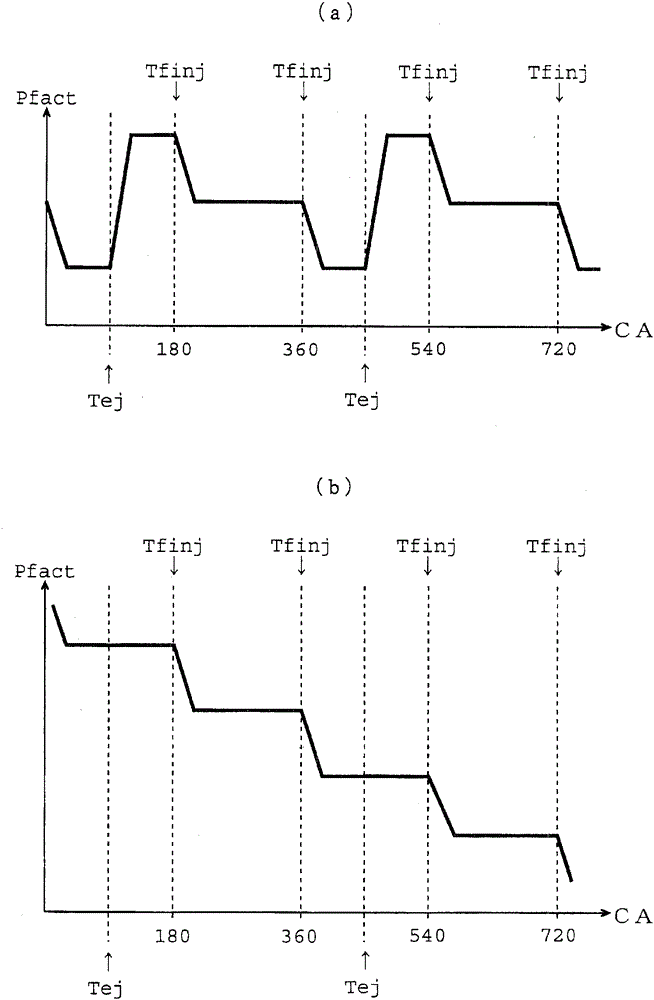

[0041] First, based on Figure 1 to Figure 4 A first embodiment of the present invention will be described. figure 1 It is a diagram showing a schematic configuration of a fuel injection control system for an internal combustion engine according to the present invention. figure 1 The fuel injection control system shown is a fuel injection control system suitable for a tandem four-cylinder internal combustion engine, and includes a low-pressure fuel pump 1 and a high-pressure fuel pump 2 . Wherein, the number of cylinders of the internal combustion engine is not limited to four, and may be more than five or less than three.

[0042] The low-pressure fuel pump 1 is a pump for pumping up fuel stored in the fuel tank 3, and is a turbo pump (scroll pump) driven by electricity. The fuel discharged from the low-pressure fuel pump 1 is guided to the fuel inlet of the high-pressure fuel pump 2 through the low-pressure fuel passage 4 .

[0043] The high-pressure fuel pump 2 is a pump...

Embodiment 2

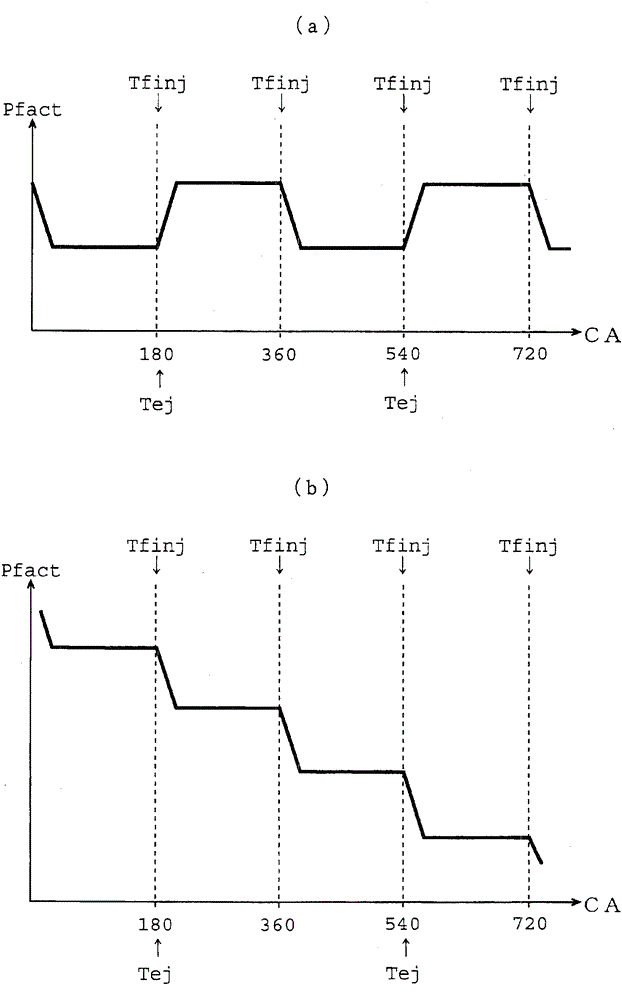

[0095] Below, based on Figure 5 to Figure 7 A second embodiment of the fuel injection control system for an internal combustion engine according to the present invention will be described. Here, configurations different from those of the first embodiment described above will be described, and descriptions of the same configurations will be omitted.

[0096] The difference between the aforementioned first embodiment and this embodiment is that there are multiple fuel injection systems including high-pressure fuel pumps. Figure 5 It is a diagram showing a schematic configuration of a fuel injection control system for an internal combustion engine in this embodiment. Figure 5 The fuel injection control system shown is a system suitable for a V-type 8-cylinder internal combustion engine. Wherein, the internal combustion engine is not limited to the V-type 8-cylinder, and may also be an internal combustion engine having a plurality of cylinder banks and each cylinder bank havi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com