Ultrasonic cmut with suppressed acoustic coupling to the substrate

An ultrasound and substrate technology, applied in the field of medical diagnostic ultrasound systems, can solve the problems of cMUT lack of commercial acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

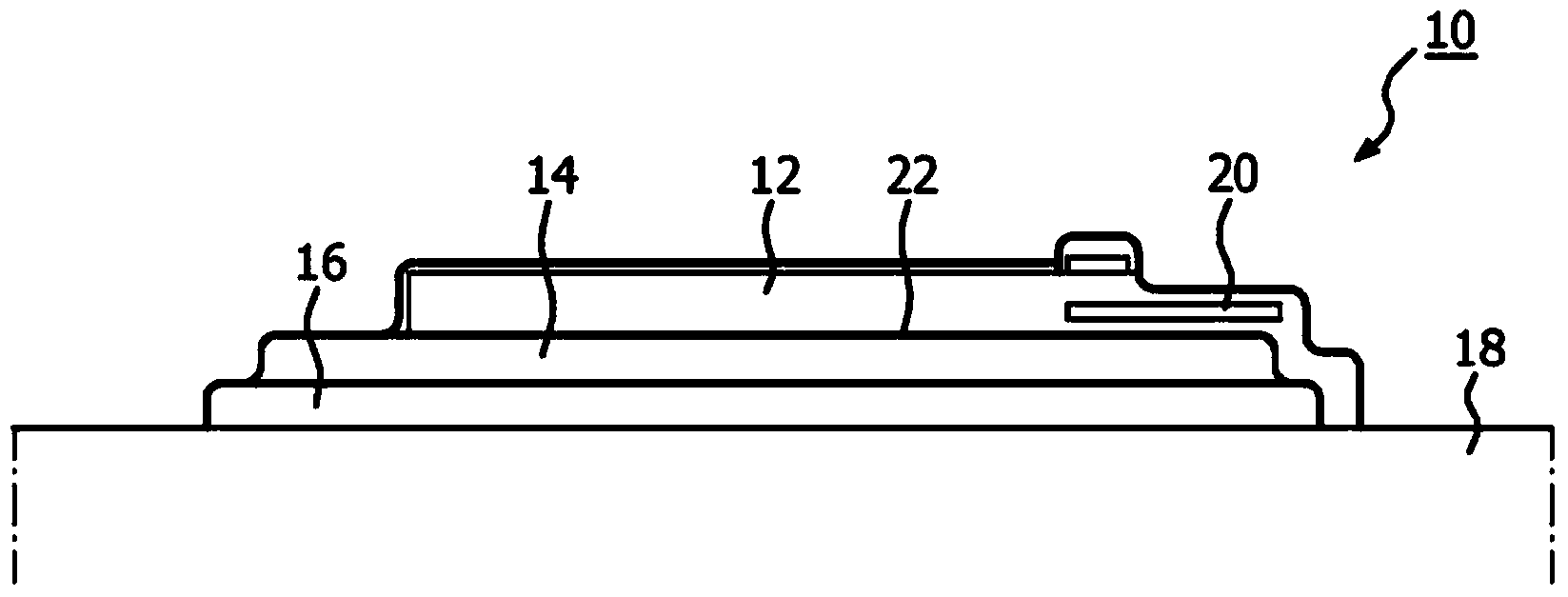

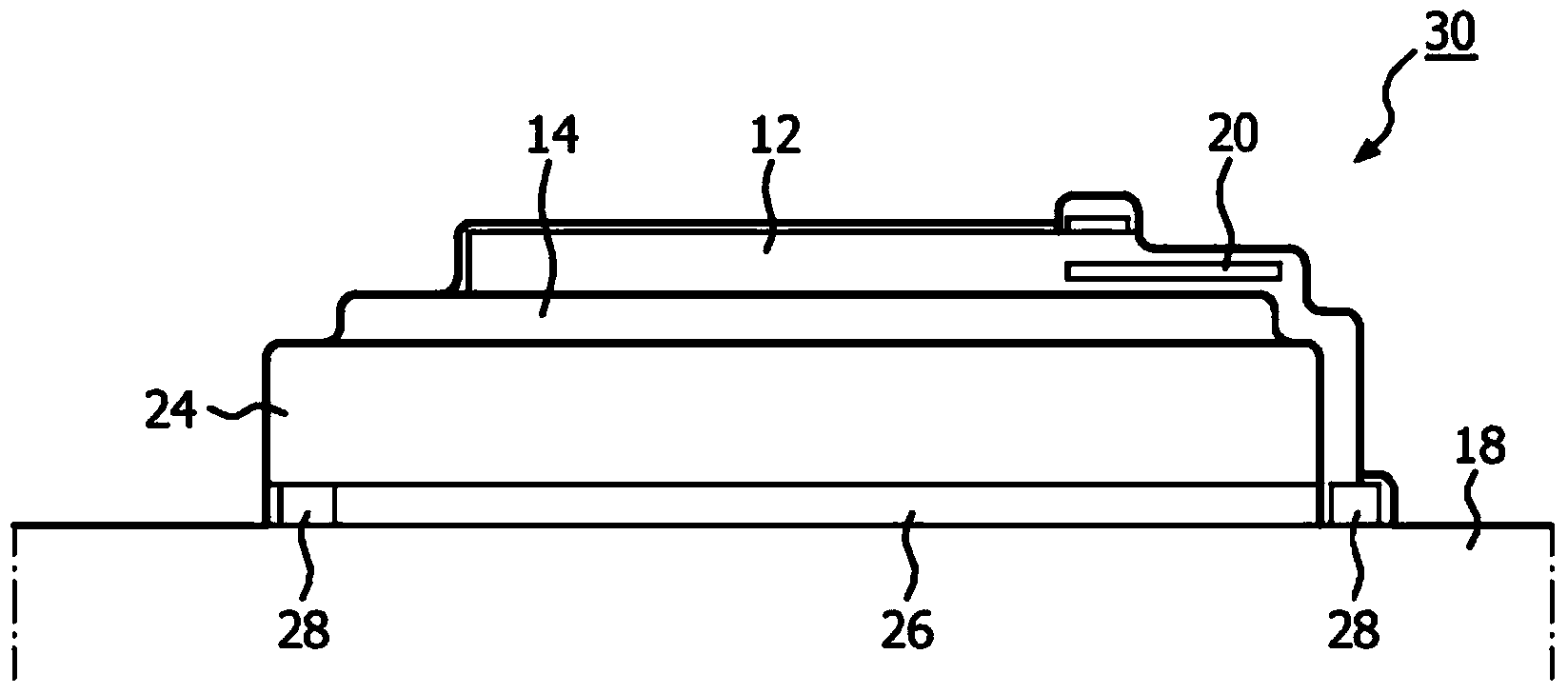

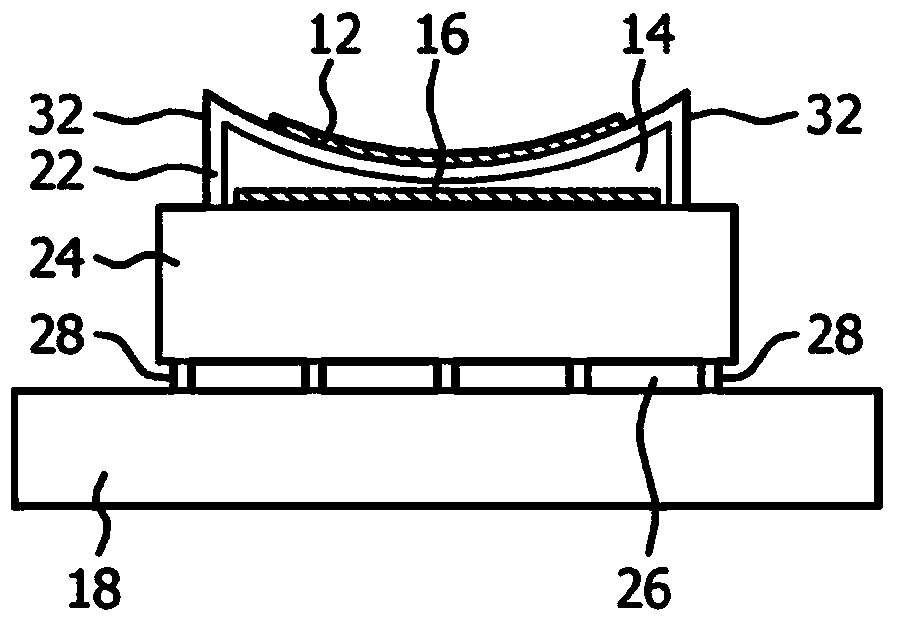

[0016] first reference figure 1 , shows a typical cMUT device 10 of the prior art through a cross-sectional view. The cMUT 10 includes a top electrode 12 composed of a conductive material. The top electrode is located on the diaphragm 22, or may itself comprise the diaphragm. In this illustration, the diaphragm is formed from a non-conductive material such as silicon nitride or silicon dioxide. The membrane is supported above the void or gap 14 by vertical supports at the lateral edges of the membrane. In this embodiment, the diaphragm spans the gap without touching the bottom of the gap bottom. In other embodiments, the diaphragm may be purposefully constructed or biased so that it operates in a collapsed mode, wherein the center of the diaphragm is in contact with the bottom of the gap. Conductor 20 couples electrical signals to or from top electrode 12 . Below the gap 14 is a bottom electrode 16 . Electrical connections to the bottom electrodes are made by the semicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com