High-voltage switch cabinet capable of changing position of grounding switch and position of current transformer

A technology for current transformers and high-voltage switchgear, applied in the field of switchgear, can solve the problems of inconvenient maintenance in the later stage of installation, unfavorable heat dissipation of components, etc., and achieve the effects of convenient product inspection, convenient busbar installation, and rationalized space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

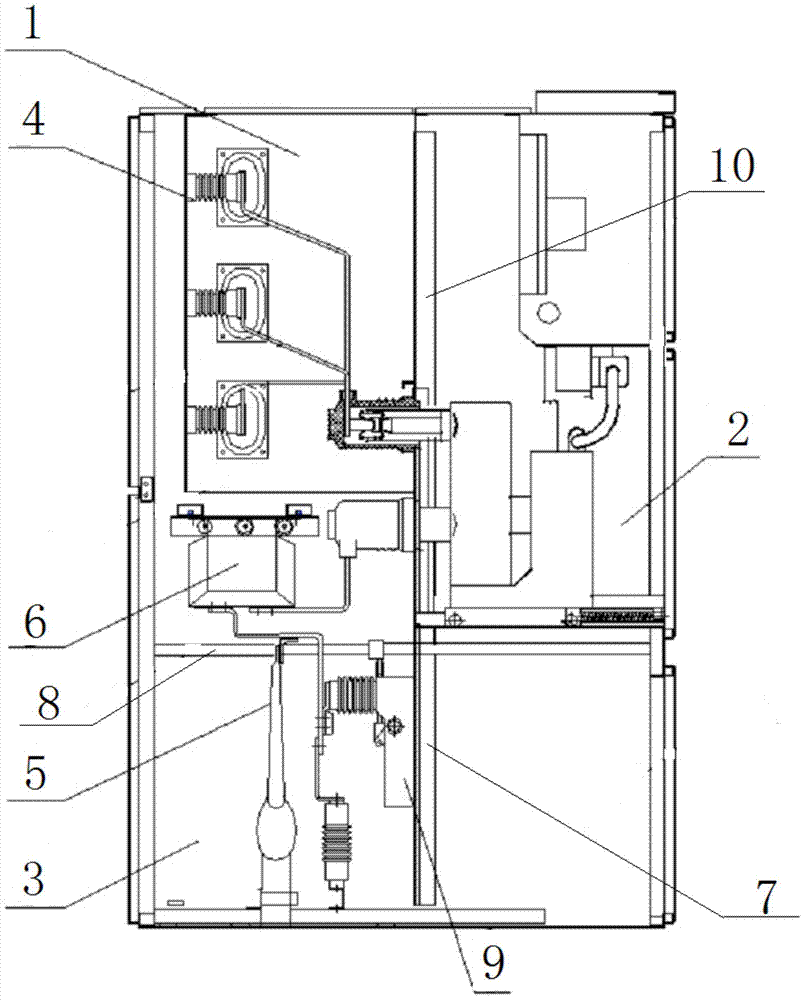

[0012] Such as figure 1 As shown, a high-voltage switchgear that changes the position of the grounding switch and the position of the current transformer is used as a power distribution device for receiving or distributing power. The upper part of the switchgear is provided with a busbar room 1 and a circuit breaker located on the side of the busbar room 1. Room 2 and the cable room 3 located below the bus room 1, the bus bar 4 is installed in the bus room 1, the incoming and outgoing cables 5 are drawn out from the cable room 3, and the current transformer 6 is installed under the bus room 1, the cable room 3 is provided with a lower partition 7, and an operating shaft 8 is installed under the circuit breaker chamber 2. A part of the operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com