An automatic stowage method to improve the stability of coil water transportation

A stable, plate-rolling technology, applied in the field of information, to achieve the effect of reducing loss, low loss and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

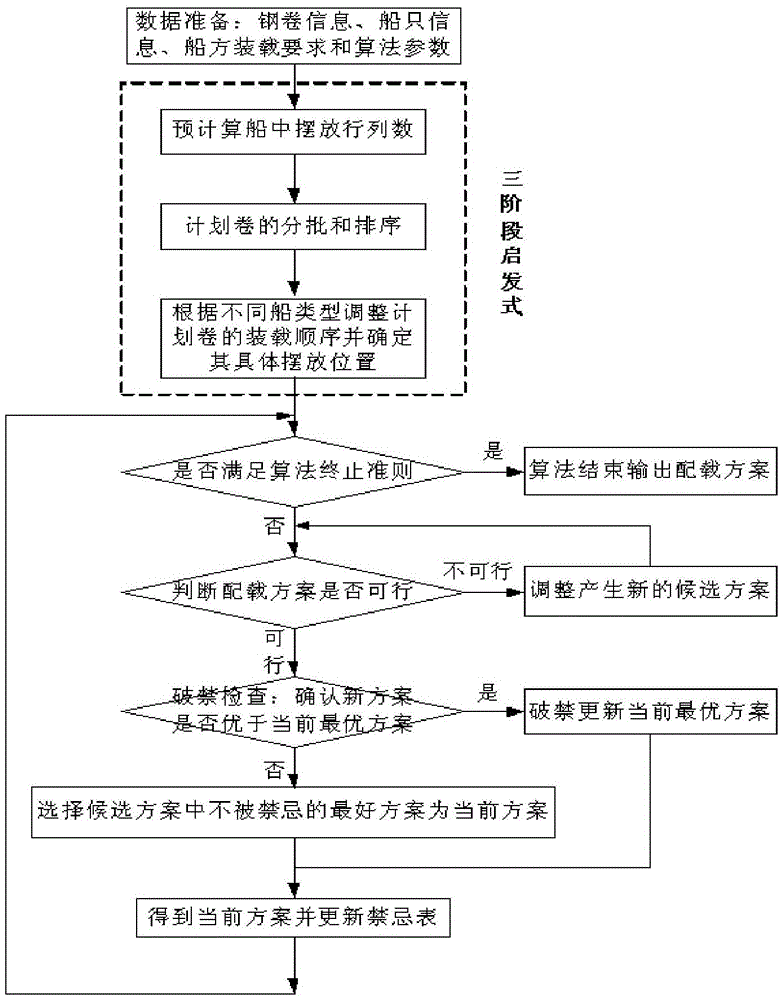

[0055] The automatic stowage method adopted in this embodiment to improve the stability of coil water transportation, its flow is as follows figure 2 As shown, it specifically includes the following steps:

[0056] Step 1: Read coil information, ship information, loading requirement information and algorithm parameter information from the database. The specific data given in this embodiment are as follows:

[0057] Take the coil as an example, including its material number, storage location number, net weight, length, width and arrival station information, as shown in Table 1:

[0058] Table 1 is the coil information table

[0059]

[0060]

[0061] Taking a single-cabin riverboat as an example, it includes the ship name, ship type, ship rated load, cabin length, and cabin width information, as shown in Table 2:

[0062] Table 2 is the ship in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com