Backlight Module

A backlight module, color light technology, applied in optics, electric light sources, nonlinear optics, etc., can solve the problems affecting the image display quality of liquid crystal display panels, yellowing of color light, etc., and achieve the effect of improving image display quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

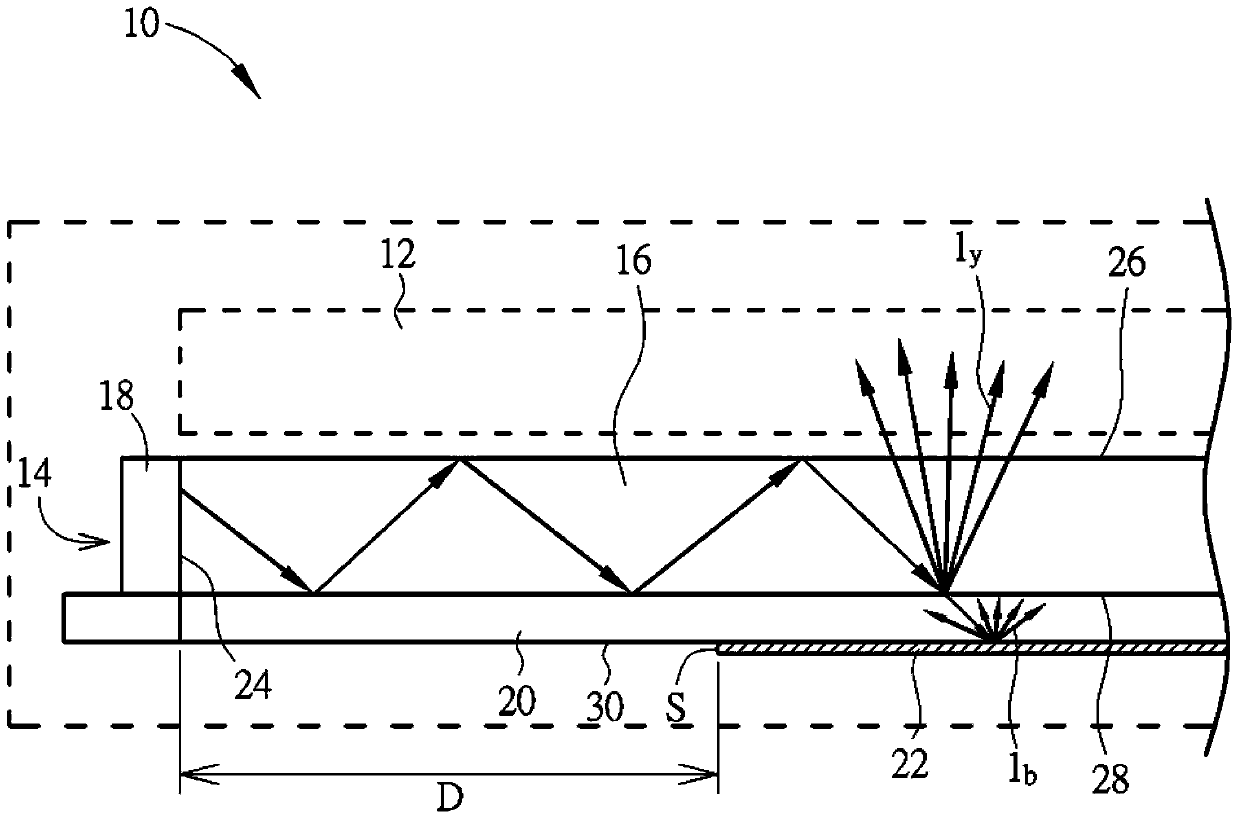

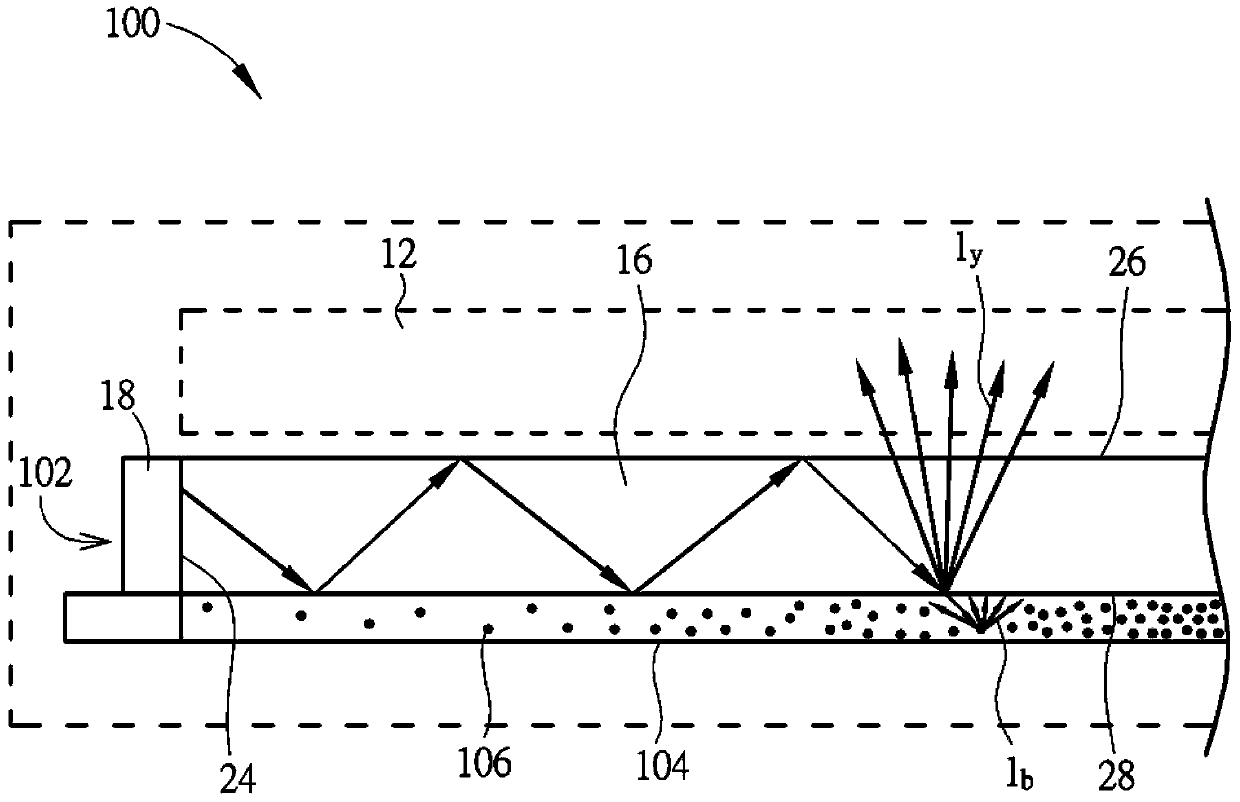

[0015] see figure 1 as well as figure 2 , figure 1 It is a schematic diagram of the appearance of a display device 10 proposed according to a first embodiment of the present invention, figure 2 for figure 1 A partial cross-sectional schematic view of the display device 10 along the section line A-A'. In this embodiment, the display device 10 can be a liquid crystal display (such as figure 1 shown), but not limited thereto, it can also be other common displays, such as liquid crystal screens applied to notebook computers. Depend on figure 1 as well as figure 2 It can be seen that the display device 10 includes a liquid crystal panel 12 and a backlight module 14, wherein the components of the display device 10 except the backlight module 14 (such as the liquid crystal panel 12, the device frame, etc.) figure 2 It is shown in dotted line. The backlight module 14 is disposed on one side of the liquid crystal panel 12 for providing white light to the liquid crystal pane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com