A double switch thermostatic valve

A dual-switch, thermostatic valve technology, applied in valve devices, multi-way valves, mechanical equipment, etc., can solve the problems of easy freezing, no effect of antifreezing, cold water regulation, etc., and achieves novel and practical structure, simple manufacturing process, and guaranteed constant temperature. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

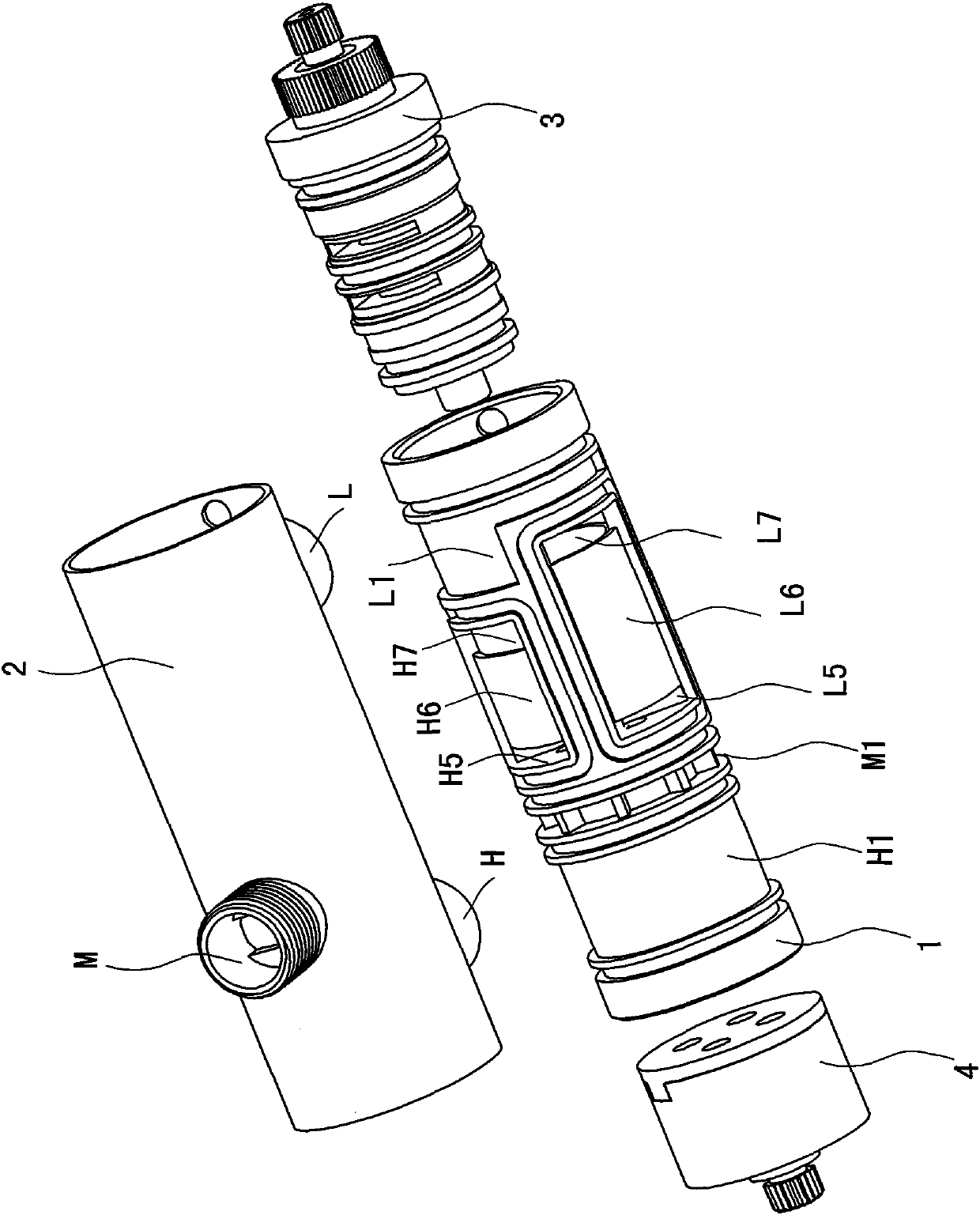

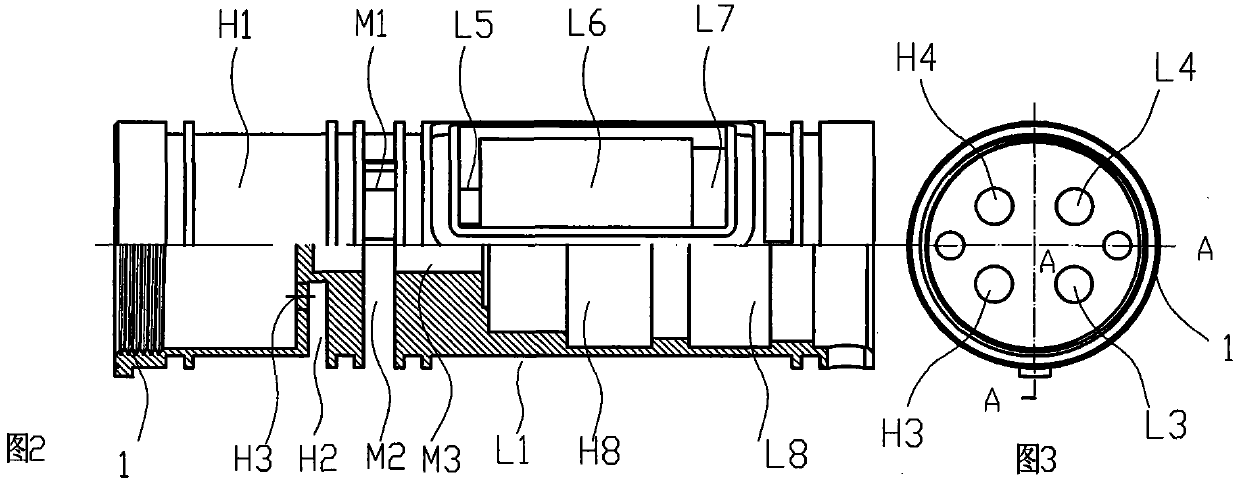

[0025] attached figure 1 It is an exploded schematic diagram of the three-dimensional structure of the present invention, which shows that it is composed of a columnar cavity 1, a valve body composed of an outer sleeve 2, a thermostatic valve core 3, and a double-switch valve core 4, wherein the thermostatic valve core 3 and the double-switch valve core 4 are all spool assemblies in the prior art, including the double switch knob and the temperature adjustment knob not shown in the figure, all of which are commonly used accessories in the prior art. image 3 It is the position diagram of the four holes for the inflow and outflow of hot and cold water on the bottom surface of the double switch valve core cavity of the columnar cavity 1 located at the left end (the switch of the thermostatic valve is generally set at the left end), and the attached figure 2 is attached image 3 Sectional view along line A-A, with Figure 4 , 5 And attached figure 2 The external and interna...

no. 2 example

[0033] attached Figure 6 and 7 As shown, on the basis of the above example, a partial annular concave cavity with the smallest area including the hot water inlet H and the hot water area outlet hole H2 is provided in a concave cavity corresponding to the hot water inlet H of the outer sleeve 2. The cavity, surrounded by the notch inlaid with the sealing ring, is the hot water zone H1. Outside the partial annular cavity, the channel connecting the water outlet hole L2 of the cold water zone and the cold water inlet hole L3 of the double switch is connected to the columnar cavity. A cooling water through hole L9 is provided on the outer peripheral surface of the body 1. This hole can overflow the cold water leading to the double switch valve core on the outer peripheral surface of the columnar cavity 1 and surround the partial annular concave cavity of the hot water zone H1. Thereby, the temperature of the outer sleeve 2 can be reduced to avoid scalding. In addition, this exa...

no. 3 example

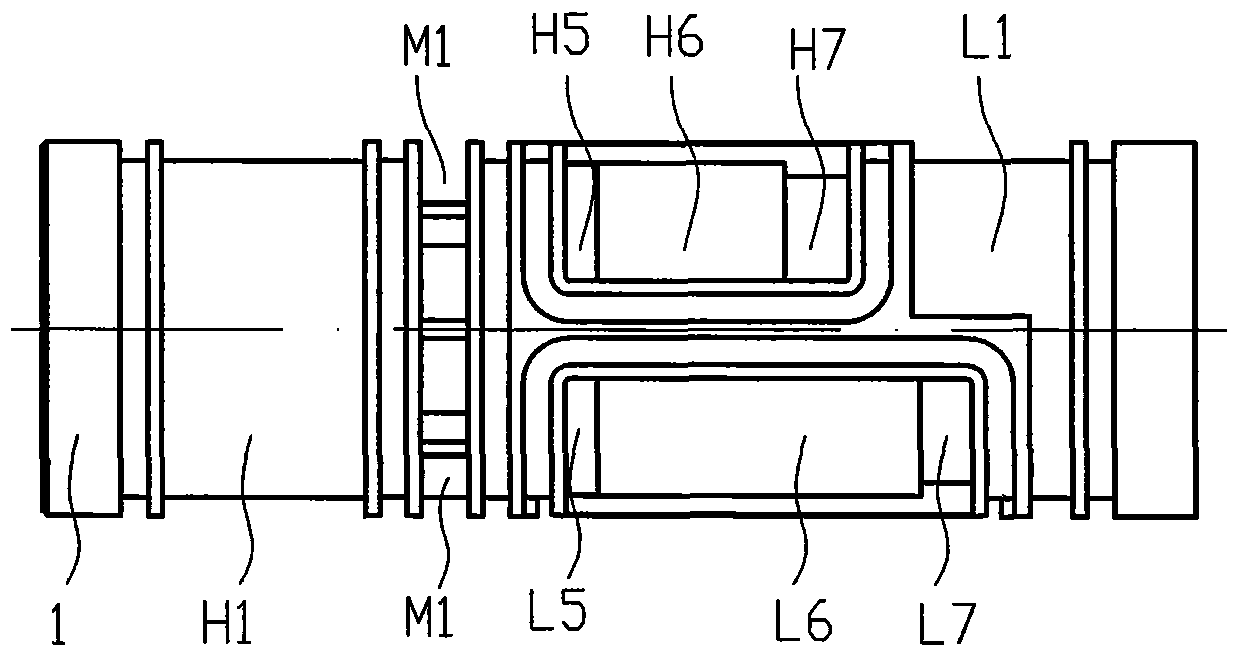

[0035] attached Figure 8 and 9 As shown, another structure of the columnar cavity 1 is that only two O-rings are arranged at both ends on its outer peripheral surface, and between the two O-rings except the hot water chamber H6 and the cold water chamber L6 In addition, there are also two partial annular concave cavities, the hot water area H1 and the mixed water outlet area M1, which respectively include the hot water inlet H and the mixed water outlet M of the outer sleeve 2, and the rest of the outer peripheral surface is the cold water area L1. The cold water area L1 can surround the hot water area H1, thereby reducing the temperature of the outer sleeve 2 and avoiding burns.

[0036] As mentioned above, the double-switch thermostatic valve of the present invention is simple in process and low in cost. It is applied to the coaxial center structure of the horizontal thermostatic valve body and realizes double-switch and double-flow control in the true sense. The synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com