Negative-pressure pressurizing two-stage reversely-installed sealed multiform impeller combination petrifaction process pump

A multi-form, process pump technology, applied in the direction of non-variable-capacity pumps, pumps, pump components, etc., can solve the problems of destroying the vacuum degree of the inner flow channel of the machine seal, reducing the cavitation performance of the pump, and entering the gas on the sealing surface, etc. Achieving good energy-saving effect and solving leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

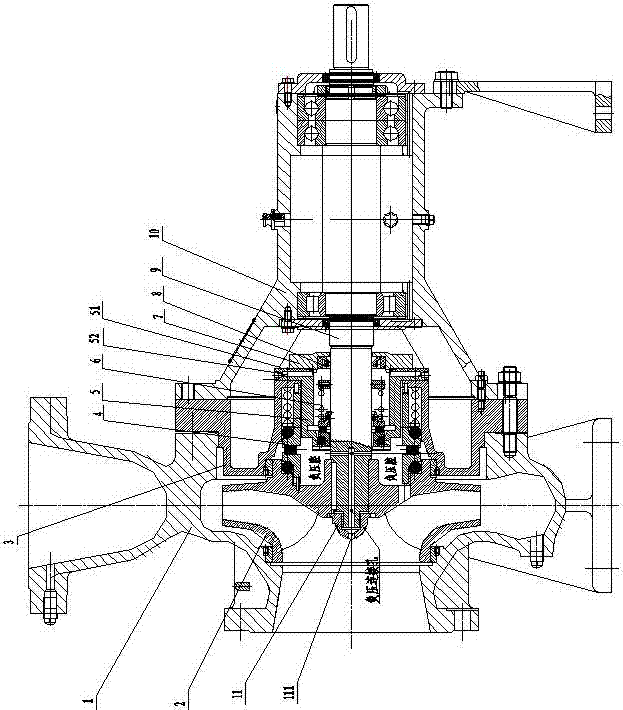

[0031] Such as figure 1 As shown, the present invention mainly consists of a pump body 1, a pump cover 3 and a suspension 10. The pump body 1 is connected to the suspension 10 through the pump cover 2, and the main shaft 9 is supported on the suspension 10 through bearings.

[0032] The front end of the main shaft 9 is connected to the impeller 2 through the impeller gland 11, and the impeller 2 is arranged in the pump body 1. Outside the main shaft 9 inside the suspension 10, an isolation cavity cover 7 is provided at the rear end of the pump cover 3.

[0033] A cylindrical isolation sleeve 5 is set between the main shaft 9 and the pump cover 3, and an annular boss 51 is set at the rear end of the isolation sleeve 5. The annular boss 51 is arranged between the pump cover 3 and the isolation cavity cover 7. A radial through hole 52 is defined on the annular boss 51 . A secondary mechanical seal device 6 provided with a spring is arranged between the cylindrical isolation sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com