A self-adaptive disturbance-free switching device for steam-driven induced draft fan in thermal power plant

A non-disturbing switching, induced draft fan technology, applied in safety devices, engine components, machines/engines, etc., can solve the problems of furnace negative pressure lack of rapid response ability, potential safety hazards, fan surge, etc., to improve safety, Improve control speed and effect, avoid passive overspeed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

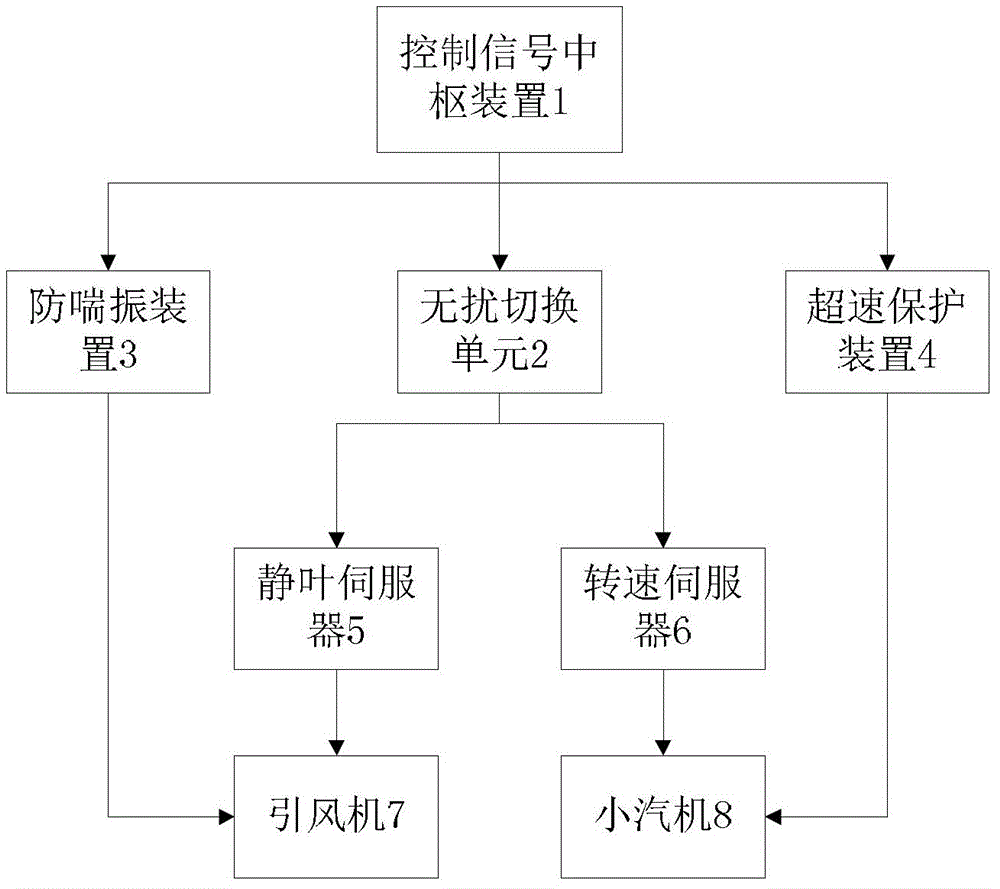

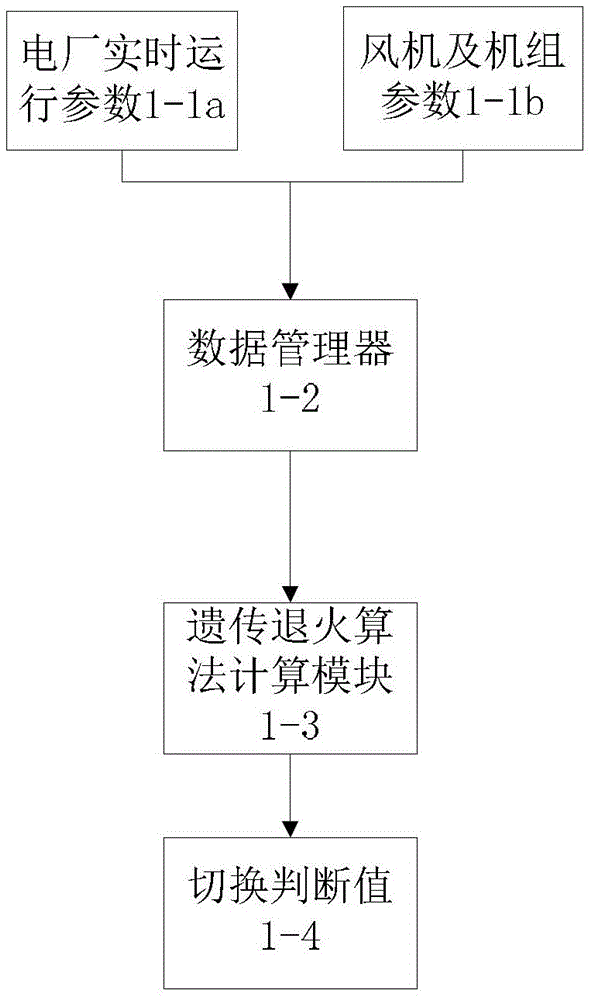

[0033] Such as figure 1 As shown, an adaptive non-disturbance switching device for a steam-driven induced draft fan in a thermal power plant of the present invention includes a control signal central device 1, a non-disturbance switching unit 2, an anti-surge device 3, an overspeed protection device 4, and a vane servo 5, speed server 6, induced draft fan 7, small steam turbine 8, the control signal central device 1 transmits the operation data received from the power plant DAS system to the non-disturbance switching unit 2, anti-surge device 3 and The overspeed protection device 4 and the non-disturbance switching unit 2 judge the switching control of the vane opening of the induced draft fan and the speed of the small steam turbine based on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com