Floor slab with preinstalled pipelines

A technology for pipelines and floors, which is applied in the field of floors with pre-installed pipelines, can solve problems such as insufficient flexibility, inconvenient installation, and inconvenient adjustments, and achieve the effects of good working environment, reduced workload, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

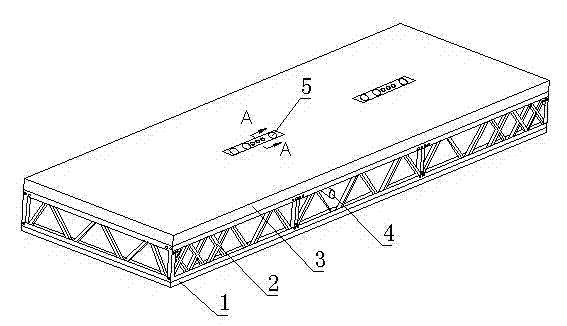

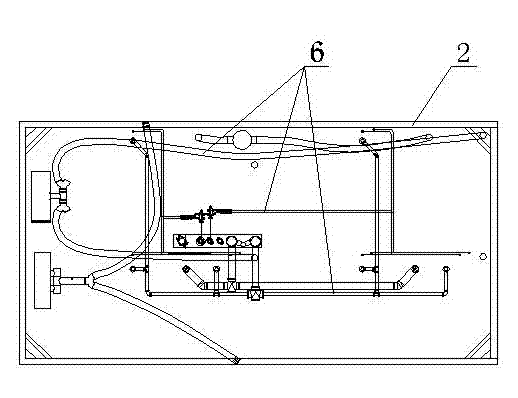

[0016] Such as figure 1 As shown, the floor slab pre-installed with pipelines includes a ceiling 1 , a floor 3 and a ceiling 1 . The ceiling 1 is provided with a floor 3 above and below the ceiling 1 . The ceiling 1 is located between the floor 3 and the ceiling 1 . Such as figure 2 As shown, the ceiling 1 is prefabricated with pipeline systems 6 such as water supply and drainage pipes, air supply pipes, exhaust pipes, garbage pipes and power distribution pipes.

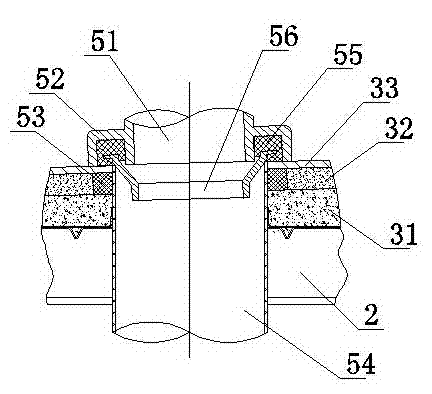

[0017] Such as figure 1 , image 3 As shown, the floor 3 is composed of a concrete layer 31, a waterproof mortar layer 32, and a floor tile layer 33. The concrete layer 31 is cast on the ceiling 1, and a waterproof mortar layer 32 is arranged above the concrete layer 31. The waterproof mortar layer The floor tile layer 33 is laid above the 32, and the pipeline interface 5 of a plurality of water supply and drainage pipes, air supply pipes, exhaust pipes, power distribution pipes, and garbage pipes is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com