Underglaze hand painting production technique of calcium porcelain

A production process and hand-painted technology, which is applied in the field of underglaze color hand-painted production process of calcareous porcelain, can solve the problems of stroke defects, blurred picture, high cost, etc., and achieve the effect of strong three-dimensional picture, full layer shade and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

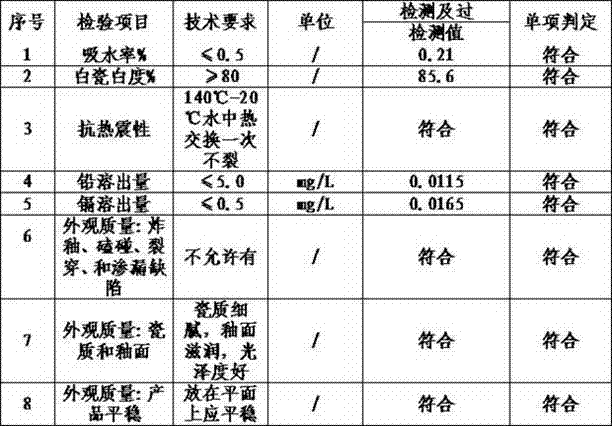

Embodiment 1

[0014] Embodiment 1, the underglaze color hand-painted production process of this kind of calcareous porcelain, adopts the following steps:

[0015] 1) Body porcelain shaping: The molded clay body is fired at 1100°C for 15 minutes to shrink and fix the shape of the body to make a porcelain body;

[0016] 2) Firing Xuan Porcelain: After spraying a layer of flux on the surface of the porcelain body, firing at 800°C for 15 minutes to make Xuan Porcelain. The composition of the flux is (in parts by weight): 32 parts of shell powder, 15 parts of feldspar powder, 28 parts of quartz powder, 10 parts of clay, 5 parts of magnesium oxide, 20 parts of water;

[0017] 3) Hand-painting: Use special coloring materials to create hand-painted creations on the surface of Xuan porcelain to make colored tires. When hand-painting, add water to the special coloring materials and mix thoroughly. The amount of water added is determined according to the color depth of the drawn pattern. (by weight):...

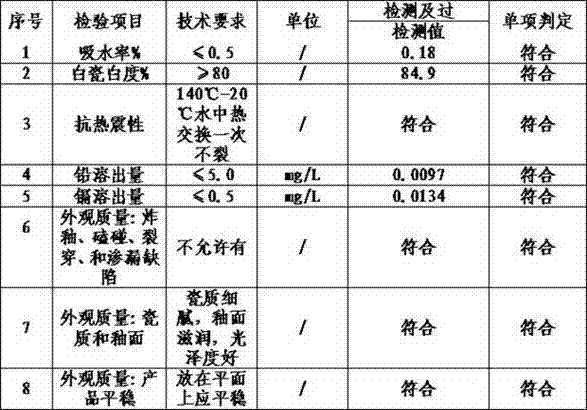

Embodiment 2

[0021] Embodiment two, the underglaze color hand-painted production process method of this kind of calcareous porcelain, adopts the following steps:

[0022] 1) Body porcelain shaping: the formed mud tire is fired at a temperature of 1280°C for 20 minutes to shrink and fix the tire shape to make a porcelain body;

[0023] 2) Firing Xuan Porcelain: After spraying a layer of flux on the surface of the porcelain body, firing at 850°C for 15-20 minutes to make Xuan Porcelain. The composition of the flux is (by weight): shell powder 35 20 parts of feldspar powder, 32 parts of quartz powder, 15 parts of clay, 10 parts of magnesium oxide, 30 parts of water;

[0024] 3) Hand-painting: Use special coloring materials to create hand-painted creations on the surface of Xuan porcelain to make colored tires. When hand-painting, add water to the special coloring materials and mix thoroughly. The amount of water added is determined according to the color depth of the drawn pattern. (by weigh...

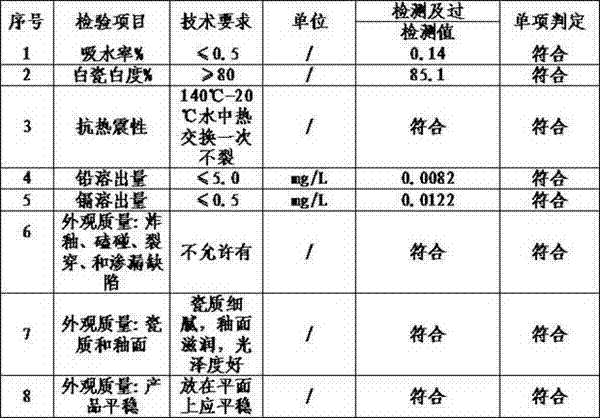

Embodiment 3

[0028] Embodiment three, the underglaze color hand-painted production process method of this kind of calcareous porcelain, adopts the following steps:

[0029] 1) Body porcelain shaping: The molded clay body is fired at 1200°C for 18 minutes to shrink and fix the shape of the body to make a porcelain body;

[0030] 2) Firing Xuan porcelain: After spraying a layer of flux on the surface of the porcelain body, firing at a temperature of 830°C for 18 minutes to make Xuan porcelain. The composition of the flux is (by weight): 33 parts of shell powder, 17 parts of feldspar powder, 30 parts of quartz powder, 12 parts of clay, 8 parts of magnesium oxide, 25 parts of water;

[0031] 3) Hand-painting: Use special coloring materials to create hand-painted creations on the surface of Xuan porcelain to make colored tires. When hand-painting, add water to the special coloring materials and mix thoroughly. The amount of water added is determined according to the color depth of the drawn pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com