A kind of hand-painted production method of underglaze color of calcareous porcelain

A production process and color hand technology, which is applied in the field of underglaze color hand-painted production process of calcareous porcelain, can solve the problems of brush stroke defects, blurry pictures, and high cost, and achieve a picture with strong three-dimensional effect, sufficient layers of shades, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

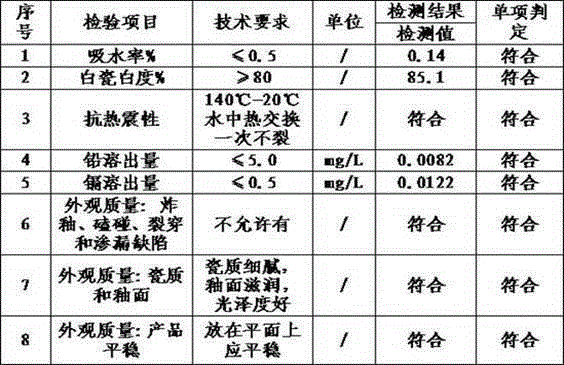

Embodiment 1

[0012] Embodiment 1, the underglaze color hand-painted production process of this kind of calcareous porcelain, adopts the following steps:

[0013] 1) Body porcelain shaping: The molded clay body is fired at 1100°C for 15 minutes to shrink and fix the shape of the body to make a porcelain body;

[0014] 2) Firing Xuan Porcelain: After spraying a layer of flux on the surface of the porcelain body, firing at 800°C for 15 minutes to make Xuan Porcelain. The composition of the flux is (in parts by weight): 32 parts of shell powder, 15 parts of feldspar powder, 28 parts of quartz powder, 10 parts of clay, 5 parts of magnesium oxide, 20 parts of water;

[0015] 3) Hand-painting: Use special coloring materials to create hand-painted creations on the surface of Xuan porcelain to make colored tires. When hand-painting, add water to the special coloring materials and mix thoroughly. The amount of water added is determined according to the color depth of the drawn pattern. (by weight):...

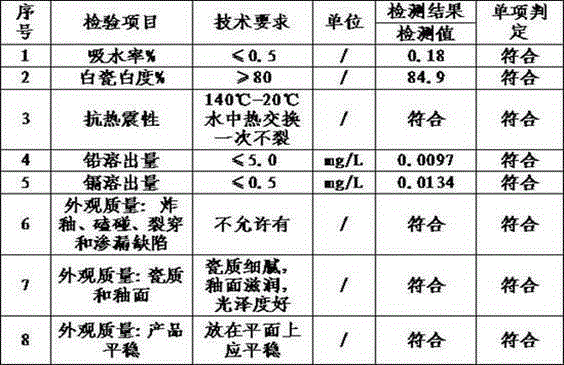

Embodiment 2

[0019] Embodiment two, the underglaze color hand-painted production process method of this kind of calcareous porcelain, adopts the following steps:

[0020] 1) Body porcelain shaping: the formed mud tire is fired at a temperature of 1280°C for 20 minutes to shrink and fix the tire shape to make a porcelain body;

[0021] 2) Firing Xuan Porcelain: After spraying a layer of flux on the surface of the porcelain body, firing at 850°C for 15-20 minutes to make Xuan Porcelain. The composition of the flux is (by weight): shell powder 35 20 parts of feldspar powder, 32 parts of quartz powder, 15 parts of clay, 10 parts of magnesium oxide, 30 parts of water;

[0022] 3) Hand-painting: Use special coloring materials to create hand-painted creations on the surface of Xuan porcelain to make colored tires. When hand-painting, add water to the special coloring materials and mix thoroughly. The amount of water added is determined according to the color depth of the drawn pattern. (by weigh...

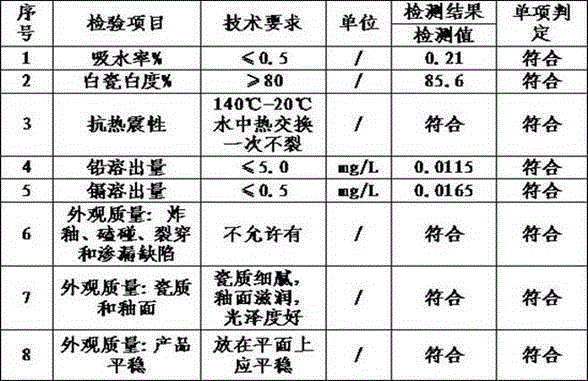

Embodiment 3

[0026] Embodiment three, the underglaze color hand-painted production process method of this kind of calcareous porcelain, adopts the following steps:

[0027] 1) Body porcelain shaping: The molded clay body is fired at 1200°C for 18 minutes to shrink and fix the shape of the body to make a porcelain body;

[0028] 2) Firing Xuan porcelain: After spraying a layer of flux on the surface of the porcelain body, firing at a temperature of 830°C for 18 minutes to make Xuan porcelain. The composition of the flux is (by weight): 33 parts of shell powder, 17 parts of feldspar powder, 30 parts of quartz powder, 12 parts of clay, 8 parts of magnesium oxide, 25 parts of water;

[0029] 3) Hand-painting: Use special coloring materials to create hand-painted creations on the surface of Xuan porcelain to make colored tires. When hand-painting, add water to the special coloring materials and mix thoroughly. The amount of water added is determined according to the color depth of the drawn pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com