Porcelain cross arm insulation baffle

A technology of insulating baffles and porcelain cross-arms, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of shortening live working time, long time consumption, and complicated operation process of insulating blankets, so as to expand the scope of insulation shielding, improve safety, Effect of reducing job complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will be described in conjunction with the accompanying drawings and a specific embodiment.

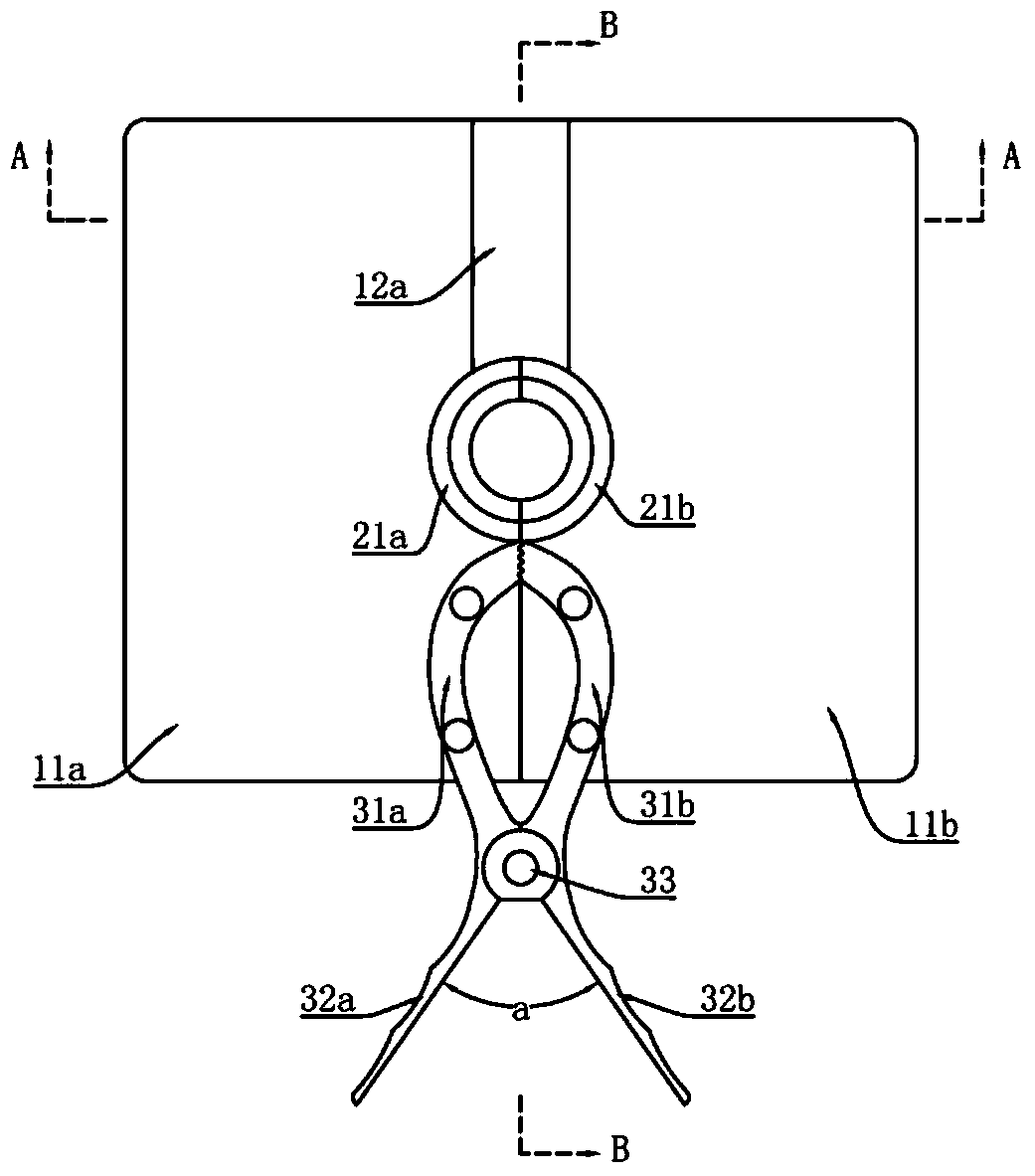

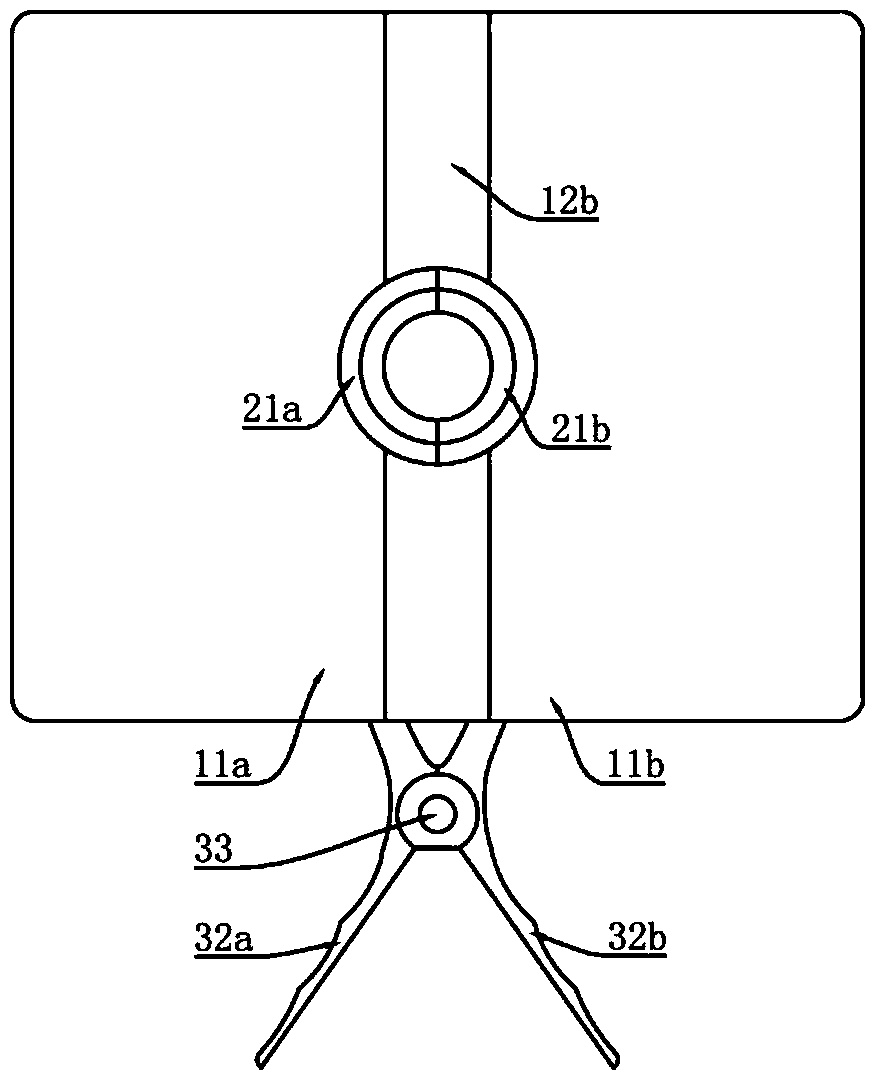

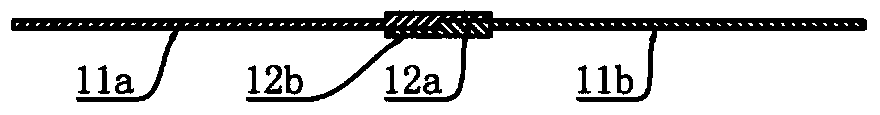

[0027] see Figure 1 to Figure 5 . The porcelain cross-arm insulating baffle described in this embodiment includes a first insulating baffle 11a and a second insulating baffle 11b, and the shapes and materials of the first insulating baffle 11a and the second insulating baffle 11b are completely the same. Both the first insulation baffle 11a and the second insulation baffle 11b are rectangular plates made of glass fiber reinforced plastics with excellent insulation properties. FRP is a reinforced plastic made of glass fiber or its products as a reinforced material, or glass fiber reinforced plastic, which is a common material in the prior art. The present invention selects light and hard, non-conductive, high mechanical strength and corrosion-resistant glass fiber reinforced plastics for use. The thickness of FRP has a certain influence on the insulation perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com