Asphalt mixture self-healing capability evaluating method

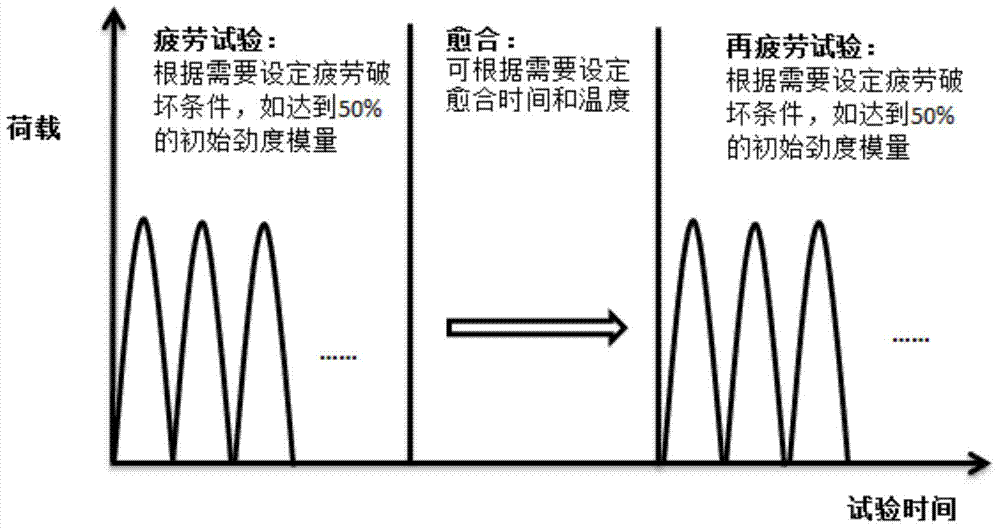

An asphalt mixture and evaluation method technology, which is applied in the direction of using a stable bending force to test the strength of the material, can solve the problems such as the failure to reflect the recovery degree of the asphalt mixture's resistance to load action, the lack of accuracy, etc., and the test method is simple and feasible. , easy to popularize, accurate and reliable test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

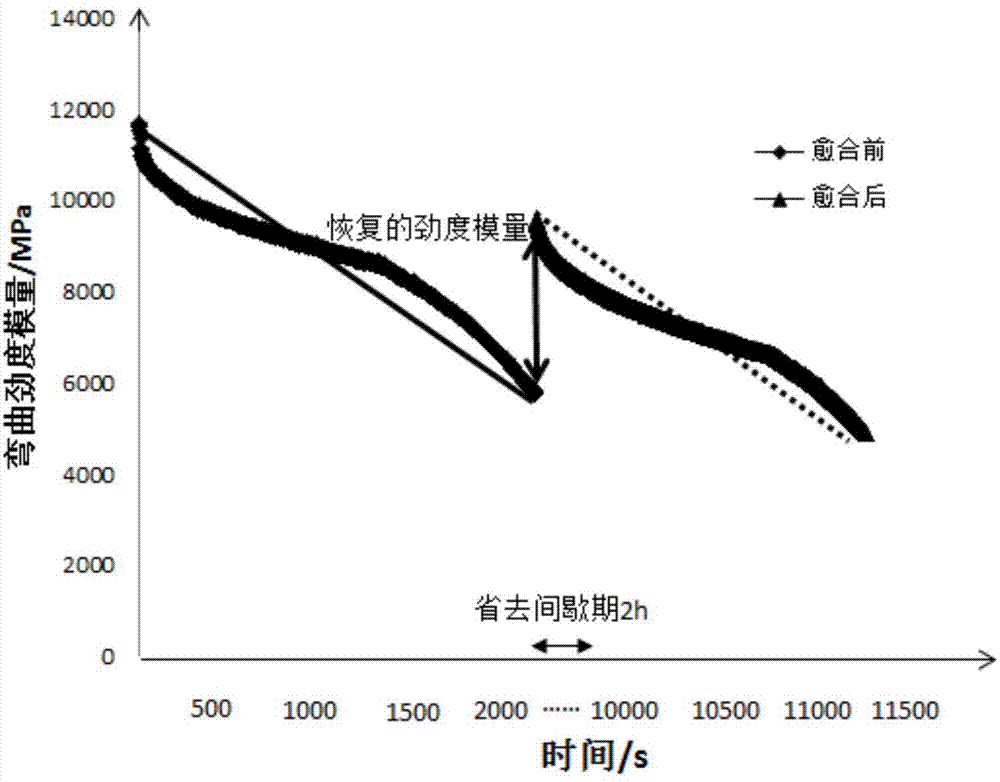

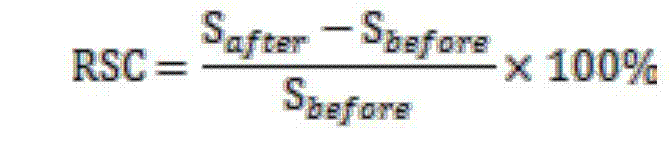

[0041] Such as figure 2 , Under the test conditions of 500 microstrain at 15℃, firstly perform fatigue test on AC-13 matrix asphalt mixture, and stop the fatigue test immediately when its stiffness modulus decays to 50% of the initial value, and introduce intermittent period That is healing time. After reaching the set time (2h in this example), the fatigue test starts immediately, that is, the fatigue test after the healing period. The black solid line in the figure indicates the damage rate when the stiffness modulus of the AC-13 matrix asphalt mixture sample decays to 50% of the initial modulus value before the introduction of the healing time; the arrow indicates the healing time after 2h (15℃ Bottom), the recovered stiffness modulus value of the specimen; the black dotted line indicates the damage rate when the stiffness modulus of the matrix asphalt mixture specimen decays to 50% of the initial modulus value after the healing time is introduced. The ratio of the two sl...

Embodiment 2

[0043] The overview of this embodiment is: comparing the self-healing ability of AC-13 SBS modified asphalt mixture and PA-13 SBS modified asphalt mixture, the best oil-stone ratio is 5.3% and 4.8%, respectively.

[0044] (1) In accordance with the four-point bending fatigue test procedure for asphalt mixture in the "Highway Engineering Asphalt and Mixture Test Regulations" JTG E20-2011, the AC-13 SBS modified asphalt mixture (sample code 1) and PA- Four-point bending fatigue test of 13-type SBS modified asphalt mixture (sample code 2). The test parameters are: test temperature is 15℃, loading frequency is 10Hz, loading waveform is partial sine wave, using controlled strain mode, strain level is 500 microstrain.

[0045] (2) Place test piece 1 and test piece 2 in a temperature control box with a temperature of 15℃ for 2 hours. The test piece should be placed horizontally on a hard glass plate or ceramic tile with a flat surface and a certain rigidity to prevent the occurrence of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com