Torque testing device under thermal vacuum environment

A test device, thermal vacuum technology, applied in the direction of measuring device, mechanical component test, machine/structural component test, etc., can solve the problems such as difficult operation and influence of no-load characteristic test of the test piece, and achieve convenient no-load characteristic The effect of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

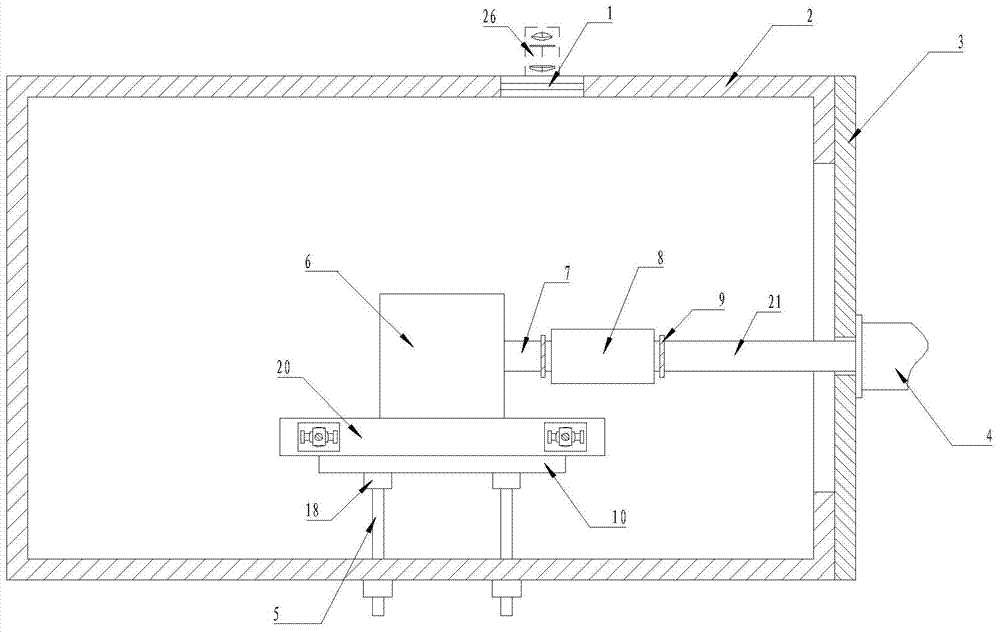

[0035] combine Figure 1 to Figure 3, a torque testing device and method in a thermal vacuum environment, the device includes an adjustment base, an observation group, a lever device, a connecting spline, a magnetic fluid sealing device, and a thermal vacuum box. The thermal vacuum box also includes a box cover 3 and a box body 2 , the box body 2 is sealed by the box cover 3 , and the magnetic fluid seal transmission shaft 21 passes through the box cover 3 . The adjustment machine base is installed in the thermal vacuum box, the connecting spline connects the output shaft 7 of the test piece and the magnetic fluid seal transmission shaft 21, the lever device is fixed in the thermal vacuum box and the paddle 9 acts on the connection On the spline, the wall of the thermal vacuum box is provided with an observation group.

[0036] The adjustment machine base includes a heavy-duty adjustment platform 20, a support platform 10, a lifting adjustment screw 5, a horizontal adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com