A kind of copolyester melt direct spinning pre-oriented yarn and preparation method thereof

A pre-oriented yarn, melt direct spinning technology, applied in the direction of single-component copolyester rayon, melt spinning, filament/thread forming, etc. type polyester composite fibers, etc., to achieve a fine three-dimensional multi-layer structure and improve the effect of crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

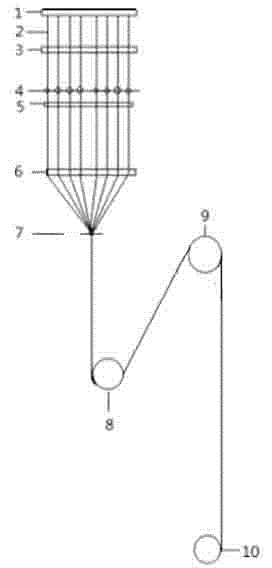

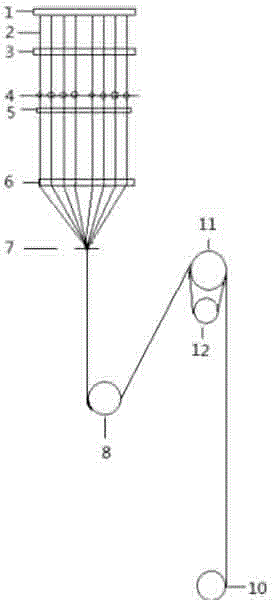

Image

Examples

Embodiment 1

[0025] This embodiment provides a kind of 47dtex / 48f copolyester melt direct spinning to prepare low-shrinkage type pre-oriented yarn, and its production process and conditions are as follows:

[0026] Put the mass fraction of 70% terephthalic acid (PTA) and mass fraction of 30% ethylene glycol (EG) as the first and second components, and inject the mixed ingredients into the slurry tank to use terephthalic acid and ethylene glycol The total amount is 100%, add catalyst ethylene glycol antimony 0.04% and additives trimethyl phosphate 0.01%, cobalt acetate 0.011%, sodium acetate 0.005%, mix and stir, and pump into the first esterification kettle through the slurry crank pump The esterification reaction then automatically flows into the second esterification tank through the liquid level difference, while adding the third component polyethylene glycol with a mass fraction of 1.0%, the fourth component diethylene glycol with a mass fraction of 0.007%, and a mass fraction of 0.01%...

Embodiment 2

[0031] This embodiment provides a kind of 178dtex / 36f copolyester melt direct spinning to prepare low-shrinkage type pre-oriented yarn, its technological process is the same as embodiment 1, and production process and condition are as follows:

[0032] In the four-pot copolymerization process, the mass fractions were respectively added: terephthalic acid (PTA) 70%, ethylene glycol (EG) 30%, the third component polyethylene glycol 1.0%, and the fourth component diethylene glycol 0.007 % and the fifth component of pentaerythritol 0.05% of the five-component monomers were copolymerized to obtain a copolyester melt.

[0033] The indicators that will meet the requirements of the spinning process are: a copolyester melt with an intrinsic viscosity of 0.631dl / g, a melting point of 255°C, and a carboxyl-terminated content of 29mol / t, which is boosted and transported to the spinning box through a melt pipeline and a booster pump spinning, the process conditions are: spinning temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com