Nitrogen fixation straw fermented fertile special for peanuts and method for producing same

A technology for fermenting fertilizer and nitrogen-fixing bacillus, which is applied in the field of nitrogen-fixing straw fermenting fertilizer for peanuts, and achieves the effects of making up for slow growth, strong nitrogen-fixing ability and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

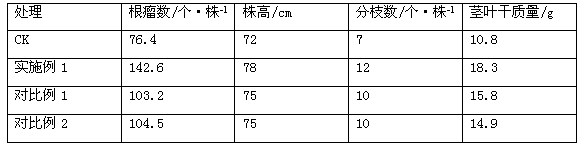

Image

Examples

Embodiment 1

[0059] The preparation method of special nitrogen-fixing stalk fermented fertilizer for peanuts comprises the following steps:

[0060] (1) Preparation of compound microbial agent:

[0061] Preparation of Bacillus nitrogen-fixing bacteria liquid: the culture method is liquid submerged fermentation, inoculate the bacteria of Bacillus nitrogen-fixing bacteria into the sterilized Erlenmeyer flask, the fermentation medium is: 0.5% starch, 0.03% yeast extract, 0.5% soybean meal, 0.2% urea, Dipotassium hydrogen phosphate 0.5%, potassium dihydrogen phosphate 0.25%, magnesium sulfate 0.1%, manganese sulfate 0.01%, pH7.0, fermentation conditions: culture temperature 37°C, stirring speed 150rpm, pH value not lower than 6.5, stirring culture After 7 hours, the live bacteria content reached 10 10 pfu / ml, to obtain the fermentation broth;

[0062] Preparation of nitrogen-fixing Bacillus megaterium bacteria liquid: the culture method is liquid submerged fermentation, inoculate the strain ...

Embodiment 2

[0088] (1) Preparation of compound microbial agent:

[0089] Preparation of Bacillus nitrogen-fixing bacteria liquid: the culture method is liquid submerged fermentation, inoculate the bacteria of Bacillus nitrogen-fixing bacteria into the sterilized Erlenmeyer flask, the fermentation medium is: 0.5% starch, 0.03% yeast extract, 0.5% soybean meal, 0.2% urea, Dipotassium hydrogen phosphate 0.5%, potassium dihydrogen phosphate 0.25%, magnesium sulfate 0.1%, manganese sulfate 0.01%, pH7.0, fermentation conditions: culture temperature 37°C, stirring speed 150rpm, pH value not lower than 6.5, stirring culture After 7 hours, the live bacteria content reached 10 10 pfu / ml, to obtain the fermentation broth;

[0090] Preparation of nitrogen-fixing Bacillus megaterium bacteria liquid: the culture method is liquid submerged fermentation, inoculate the strain of nitrogen-fixing Bacillus megaterium into a sterilized Erlenmeyer flask, the fermentation medium is: starch 0.5%, glucose 0.5%, ...

Embodiment 3

[0095] (1) Preparation of compound microbial agent:

[0096] Preparation of Bacillus nitrogen-fixing bacteria liquid: the culture method is liquid submerged fermentation, inoculate the bacteria of Bacillus nitrogen-fixing bacteria into the sterilized Erlenmeyer flask, the fermentation medium is: starch 0.1%, yeast extract 0.01%, soybean meal 0.2%, urea 0.1%, Dipotassium hydrogen phosphate 0.1%, potassium dihydrogen phosphate 0.1%, magnesium sulfate 0.05%, manganese sulfate 0.01%, pH7.0, fermentation conditions: culture temperature 37°C, stirring speed 150rpm, pH value not lower than 6.5, stirring culture After 7 hours, the live bacteria content reached 10 10 pfu / ml, to obtain the fermentation broth;

[0097] Preparation of nitrogen-fixing Bacillus megaterium bacteria liquid: the culture method is liquid submerged fermentation, inoculate the strain of nitrogen-fixing Bacillus megaterium into a sterilized Erlenmeyer flask, the fermentation medium is: starch 0.5%, glucose 0.5%, ye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com