Composite slag remover and manufacturing process thereof

A composite material and manufacturing process technology, applied in the direction of settlement tanks, etc., to achieve the effect of overcoming fragility, precise installation geometric dimensions, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

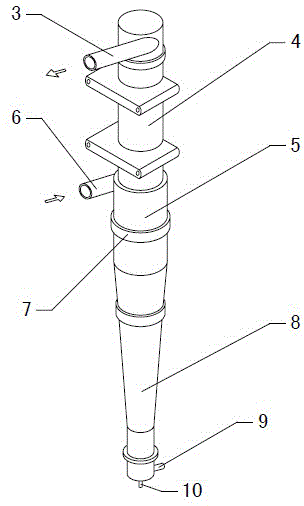

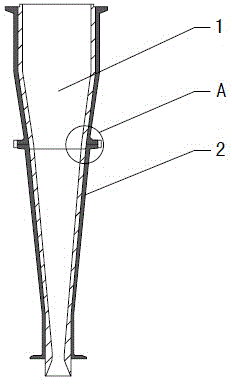

[0041] Figure 1~5 It is the best embodiment of the composite material slag remover and its manufacturing process of the present invention, below in conjunction with the attached Figure 1~6 The present invention will be further described.

[0042] Refer to attached figure 1 : Composite material slag remover, from top to bottom includes a cylindrical main body 4, a slurry feed head 5 and a cone-shaped cone 8 with a large upper part and a smaller lower part. The upper end of the main body 4 is provided with an end cover. A good pulp outlet 3 is provided in the direction, and a pulp inlet 6 is arranged tangentially on the pulp inlet head 5. The pulp inlet 6 and the good pulp outlet 3 are respectively located on both sides. The lower end of the cone 8 is provided with a horizontal slag outlet 9, and the bottom is provided There is a vertical flush port 10.

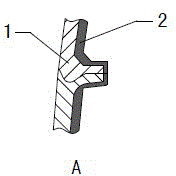

[0043] refer to Figure 2~3 , the main body 4, the pulp feeding head 5 and the cone 8 all have an isostatically pressed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com