Multifunctional cooked food baking house

A multi-functional, cooked food technology, applied in food ovens, baking, food processing, etc., to achieve the effects of uniform ripening, cost reduction, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

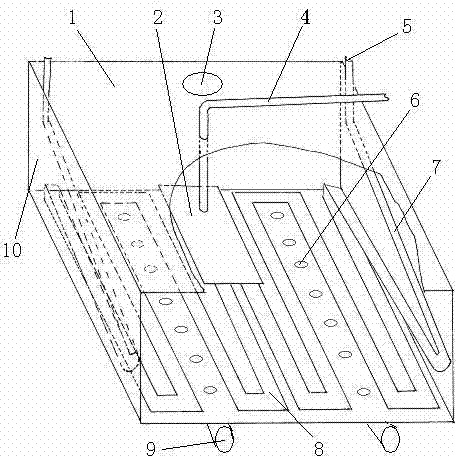

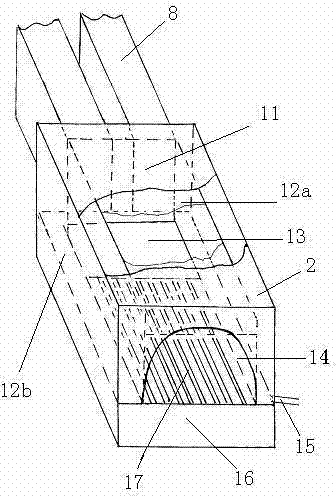

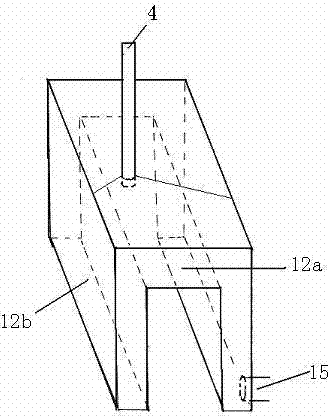

[0018] The technical solution will be further described below in conjunction with the accompanying drawings as an embodiment.

[0019] refer to figure 1 , 2 5. The barn is made into a cuboid shape, and the combustion furnace 2 is installed in the middle of the bottom wall on the ground side. The entrance of the bottom heat dissipation air duct 8 is connected to the rear part of the furnace 14 of the combustion furnace, that is, the two parts of the furnace rear part 13. The opening 11 is connected to the entrances of the two cooling air ducts on the ground. Two bottom heat dissipation air ducts 8 are connected from the rear of the furnace and then extend to the front wall, one to the left and the other to the right, turning horizontally for 50 to 80 cm long and then turning to one of the rear walls, and so on. Turn it again until it covers the bottom of the barn, forming two heat dissipation air ducts with the same position and symmetrical shape, so as to disperse the heat g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com