An oil-immersed high-voltage fuse

A high-voltage fuse, oil-immersed technology, used in electrical components, circuits, emergency protection devices, etc., can solve problems such as inconvenience, difficulty, and increased troubleshooting, and achieve the effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the technical solutions of the present invention, specific embodiments will be described in detail below in conjunction with the accompanying drawings.

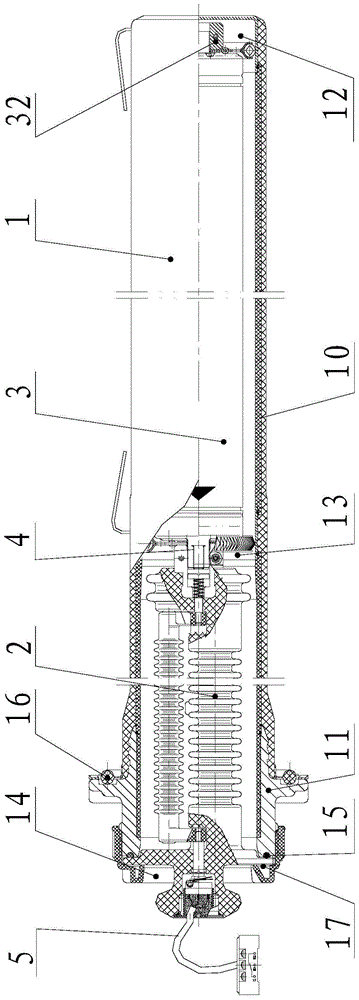

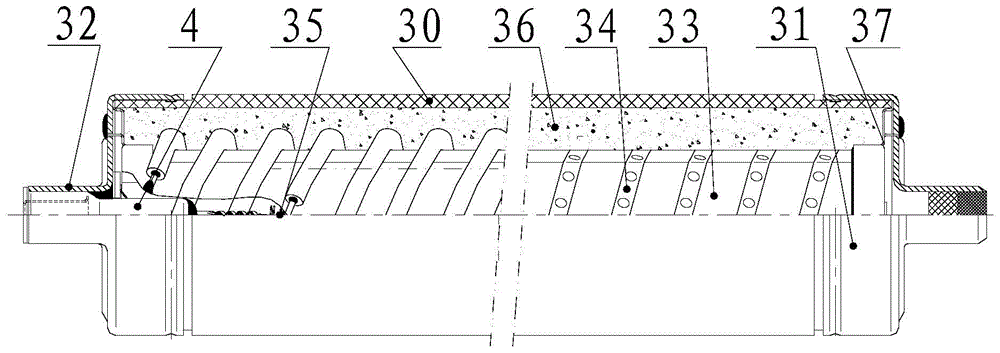

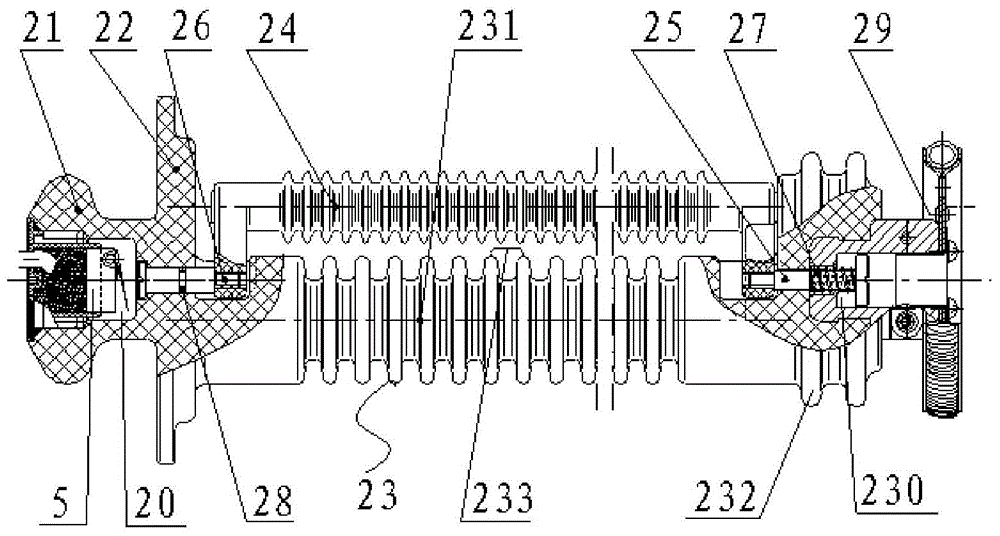

[0033] see Figure 1 to Figure 10, the oil-immersed high-voltage fuse of the present invention includes a cylindrical base with one-way opening, a fuse carrier 2 and a fuse 3 arranged in the base in sequence from the opening direction of the base, a striker 4 and a signal output device 5;

[0034] The base 1 includes a cylindrical shell 10, a base 11 which is integrated with the shell 10 and is located at the mouth of the shell 10, two conductive rings 12, 13 respectively fixed on the inner cavity wall of the shell 10 and a sealing device. A protective cover 14 at the opening of the housing 10; wherein, a ring groove is provided on the rear end surface of the base 11 for installing a sealing ring 15, and a sealing ring 16 of a special structure is provided on the side of the base 11 in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com