High-speed drive shaft oil-return device

A high-speed transmission and transmission shaft technology, which is used in the driving device, engine components, and engine lubrication of metal rolling mills. hood lock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

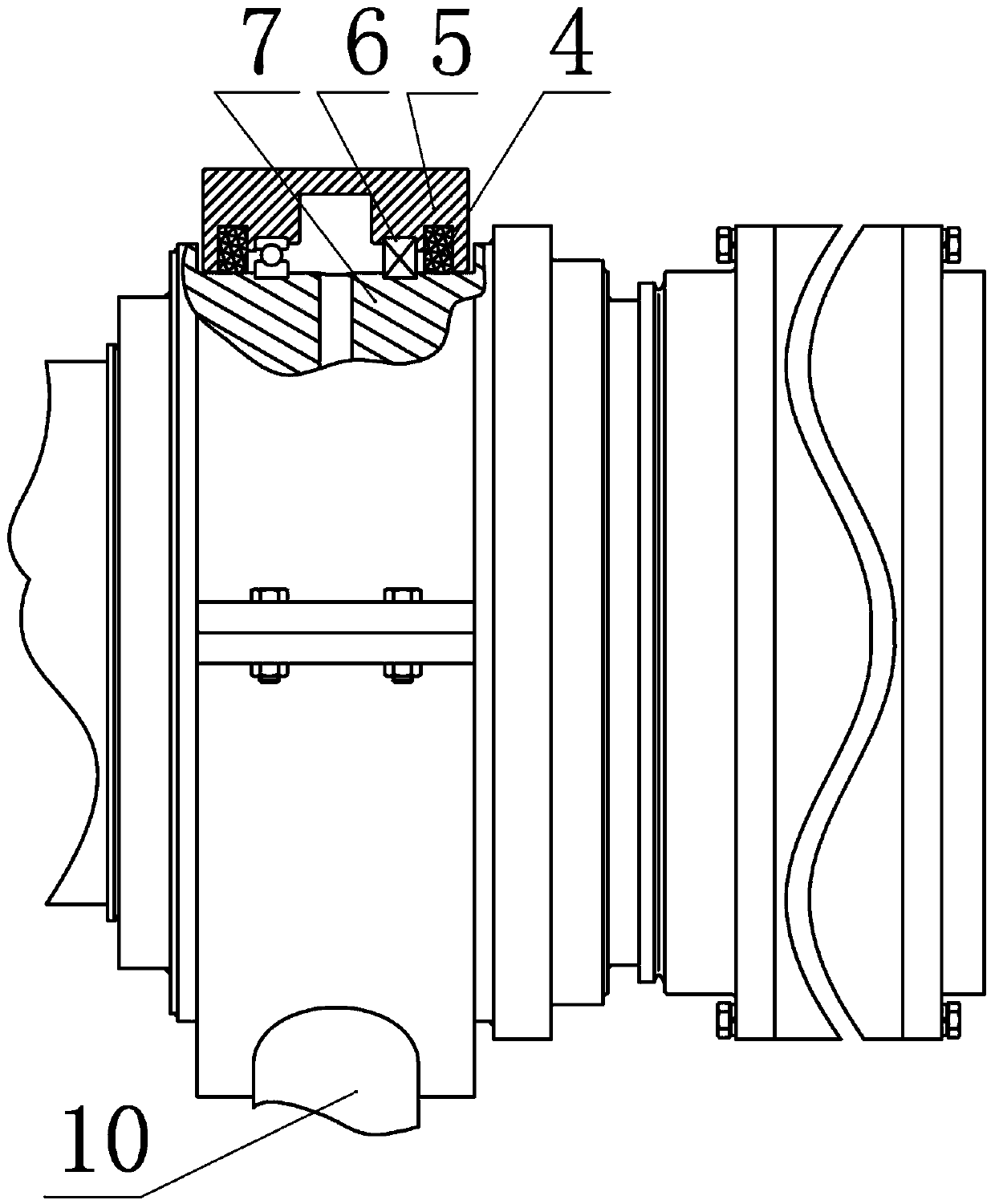

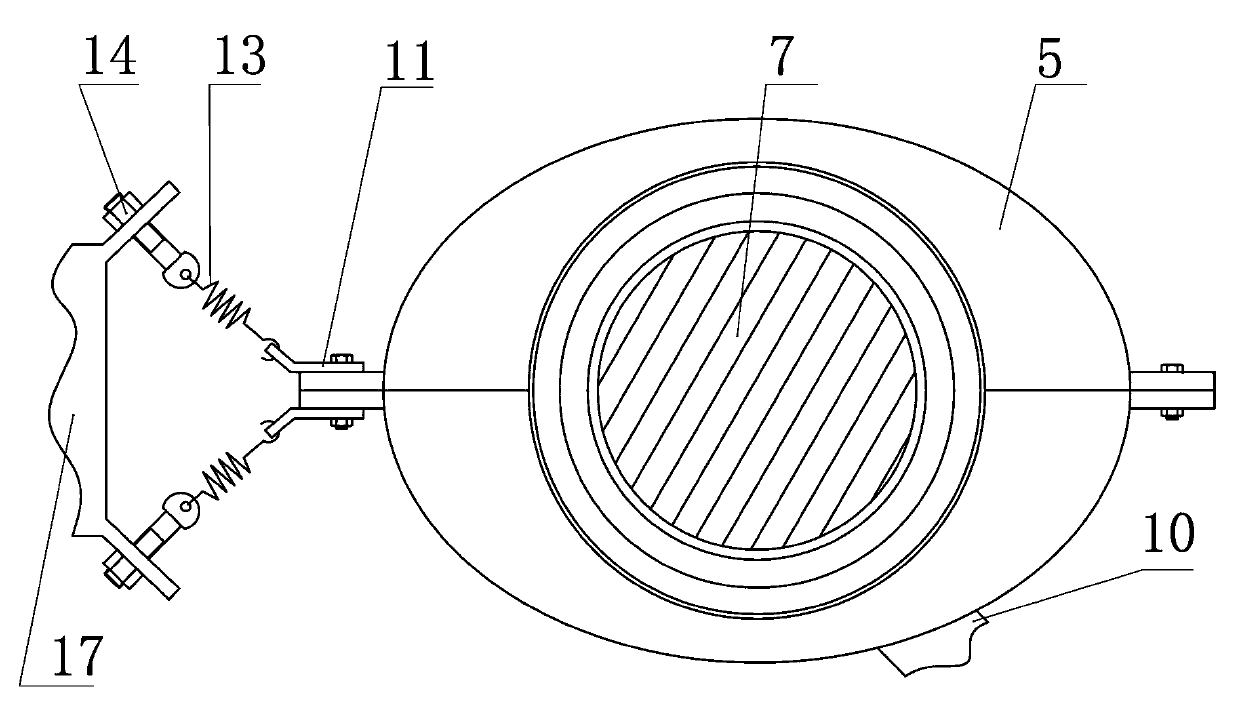

[0010] A high-speed transmission shaft oil return device, such as figure 1 , figure 2 As shown, the oil return device includes upper and lower halves of the oil return cover 5. The two halves of the oil return cover 5 are closed and wrapped in an oval shape on the outer periphery of the oil outlet section of the transmission shaft 7 of the rolling mill. The middle part of the two halves of the oil return cover 5 is concave Oil return tank, the oil return tank corresponds to the oil outlet section, the oil return covers on both sides of the oil return tank are respectively provided with bearings 6 and oil seals 4 from the inside to the outside, the bearings 6 are installed on the transmission shaft 7 of the rolling mill, and the oil return The bottom side of the cover 5 is provided with an oil return port 10, one side of the oil return cover 5 is connected together by bolts, and the other side of the oil return cover 5 is provided with an upper and lower ring 11 connected by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com