Open oil seal with seal interference

An oil seal and interference technology, which is applied in the field of coil springs, can solve the problems of unreliable sealing performance and achieve good sealing performance and convenient oil seal replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

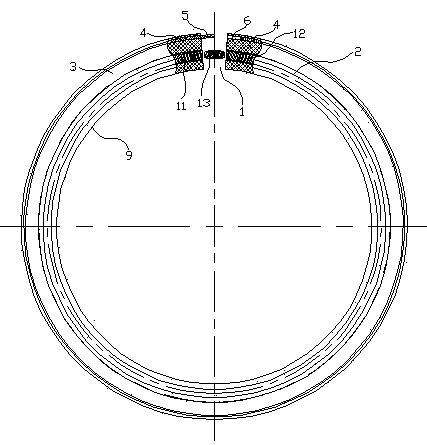

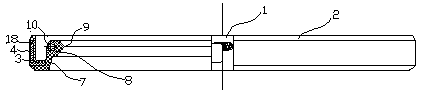

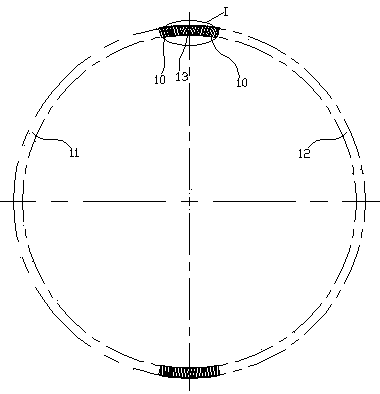

[0029] Figure 1~Figure 6 Among them, the open oil seal with sealing interference is an opening 1 circular rubber product 2, the oil seal has an open circular bottom ring 3, and the bottom ring has a rectangular open circular steel skeleton 4 with a rectangular cross section, and the opening of the steel skeleton is two There are matching tenons 5 and grooves 6 between the ends, and the inner circumference of the bottom ring is connected with an open circular ring waist 7 with an open circular cutting edge ring 8, and the inner circumference of the cutting edge ring has an open circular sealing lip 9. There is an open annular two-way helical spring frame 10 in the edge ring, and the two-way helical spring frame has left and right helical springs 11, 12 connected to each other with equal length and opposite spiral directions. The circumference of the inner circumference of the edge ring is Less than the circumference of the matched rotating shaft, two-way helical joints 13 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com