a construction machinery

A technology of construction machinery and switching mechanism, which is applied in the direction of cranes, buildings, building structures, etc., can solve the problems of difficult space layout, large impact of oil cylinder, loose structure, etc., and achieve stable unfolding and retracting movements, compact structure, and less idle periods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

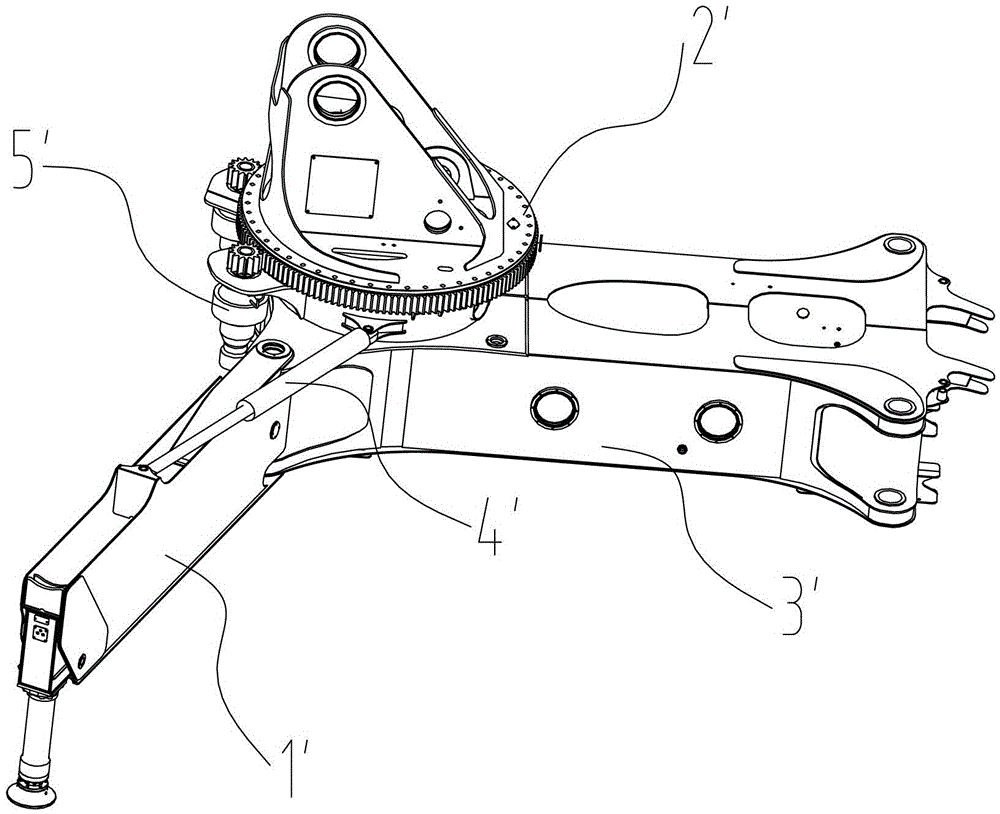

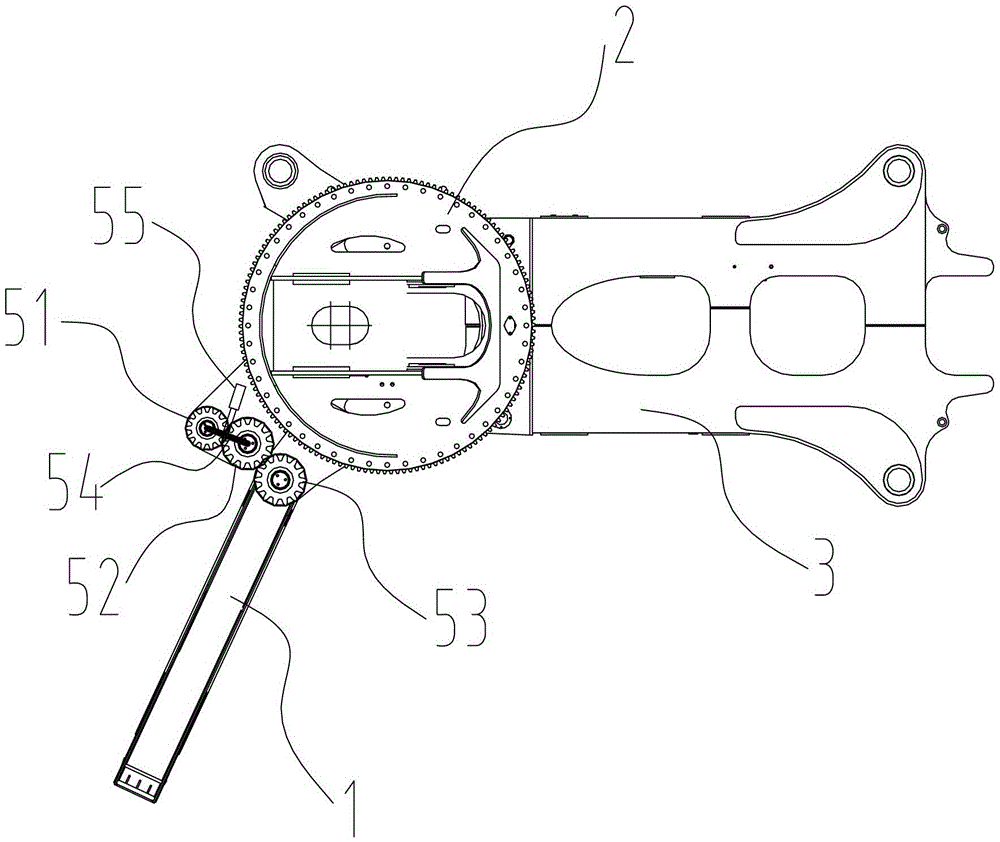

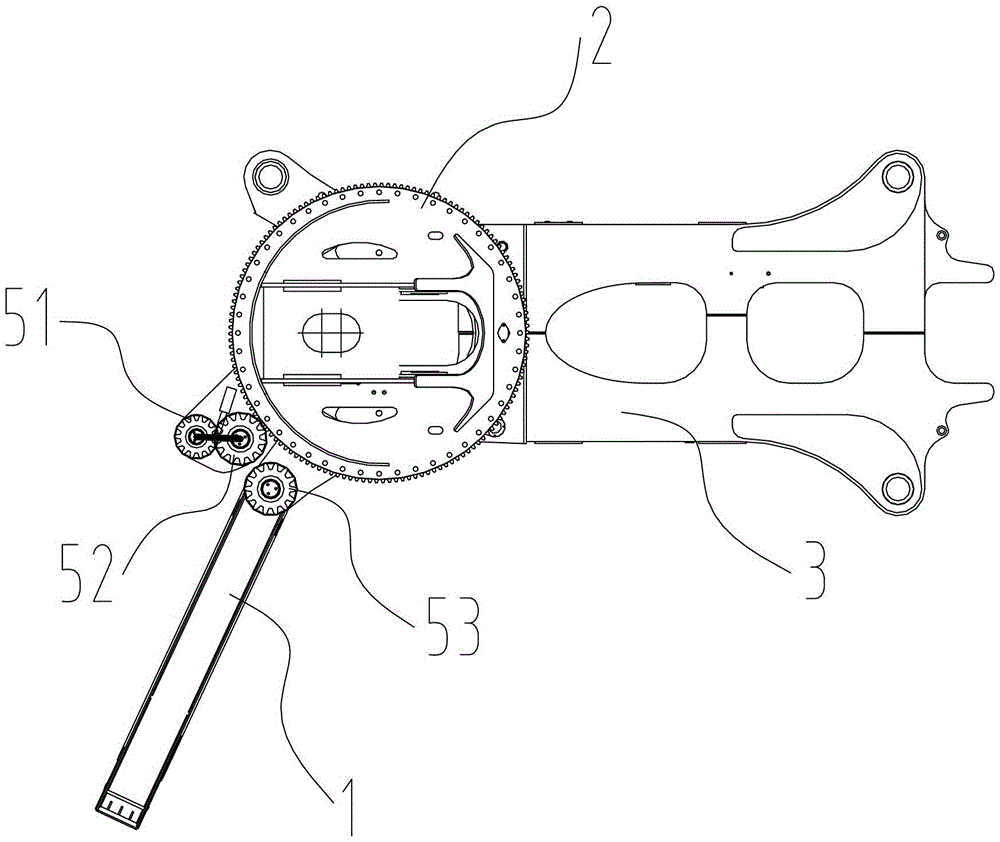

[0040] figure 2 and image 3 Shown is a schematic diagram of a construction machine according to an embodiment of the present invention, wherein figure 2 Shown is the state when the outrigger moves, image 3 Shown is the state when the slewing mechanism is in motion. In this embodiment, the construction machine includes an outrigger 1 , a slewing mechanism 2 and a vehicle body 3 . Wherein, the outrigger 1 can swing or stretch relative to the vehicle body 3, and the slewing mechanism 2 can rotate relative to the vehicle body 3 in a horizontal plane, and the specific structure of each part can refer to existing and improved technologies.

[0041] The engineering machine of this embodiment al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com