Cement mixing pile composite supporting system provided with peripheral concrete members

A technology for cement mixing piles and composite support, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of affecting construction period, large width, low tensile strength of cement mixing piles, etc. Widen the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

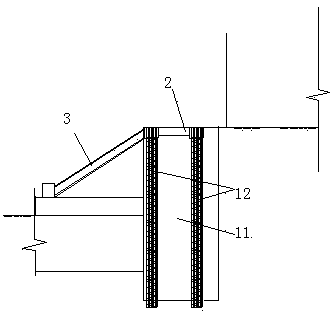

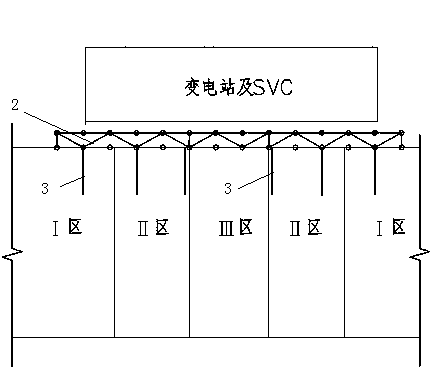

[0013] Such as figure 1 Shown: a cement mixing pile composite support system with concrete components on the periphery, including composite piles arranged around the foundation pit, concrete trusses 2 arranged on the top of the composite pile, and steel inclined piles between the bottom of the composite pile foundation pit Support 3.

[0014] see figure 2 The composite pile includes a cement mixing pile 11 and cast-in-place piles 12 on both sides thereof.

[0015] In the invention, cast-in-situ piles are arranged on both sides of the cement mixing pile, and concrete trusses are arranged on the top to form a composite support structure, and then the safe excavation of the foundation pit is realized through a divisional excavation method. It mainly solves the problems that the tensile strength of the cement mixing pile is too low, and it is easy to cause local damage when the support is set.

[0016] The front and rear rows of piles and the top concrete truss of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com