Air-uniformizing and thermoforming baking oven

A shaping oven and air heat technology, applied in the field of spinning, can solve the problems of heater aging, random wind direction, and different temperature, and achieve the effects of stabilizing fiber heat setting, prolonging service life, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

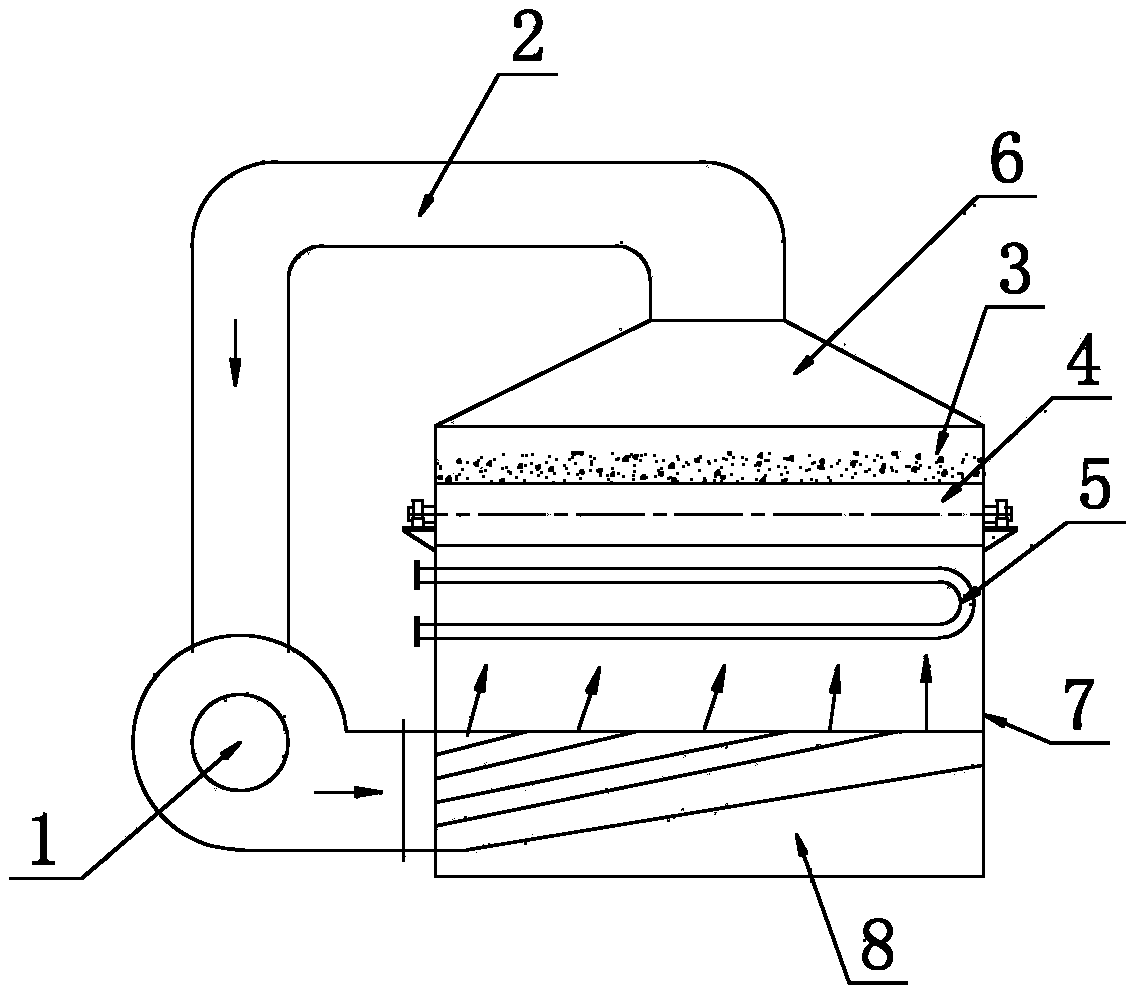

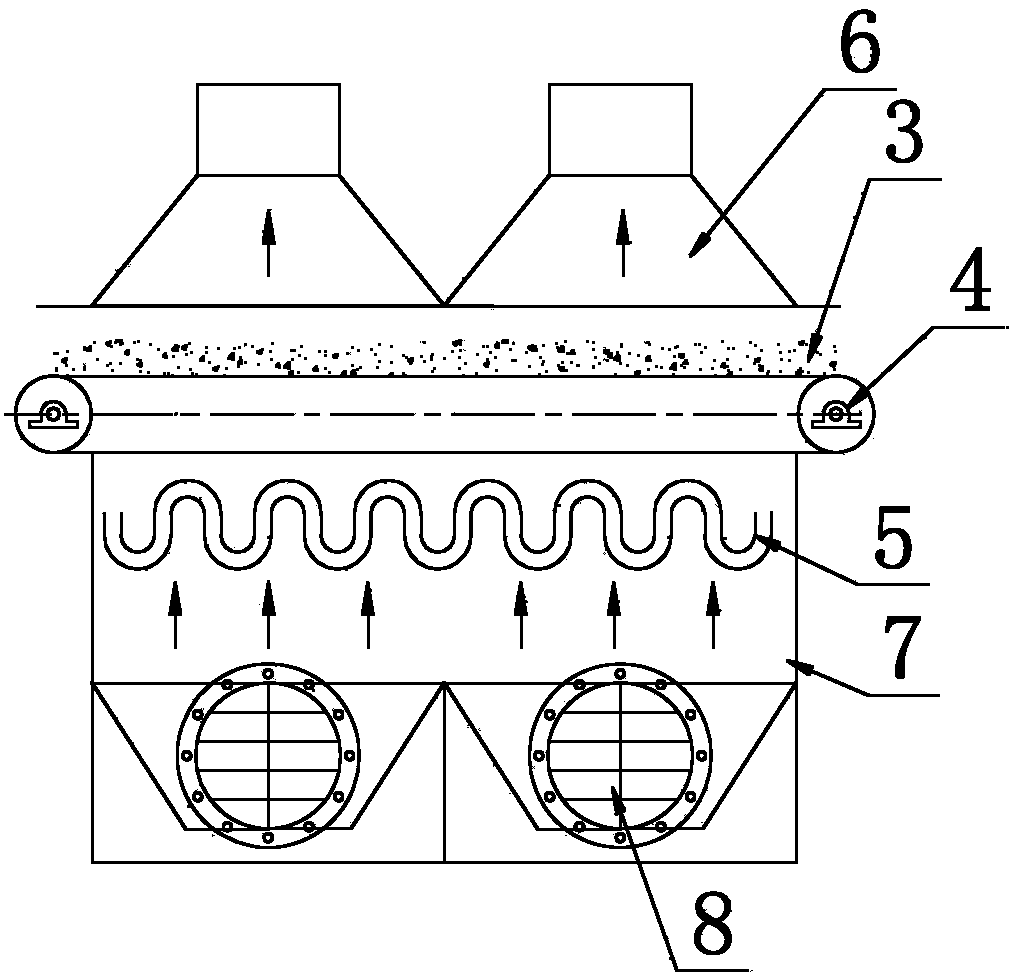

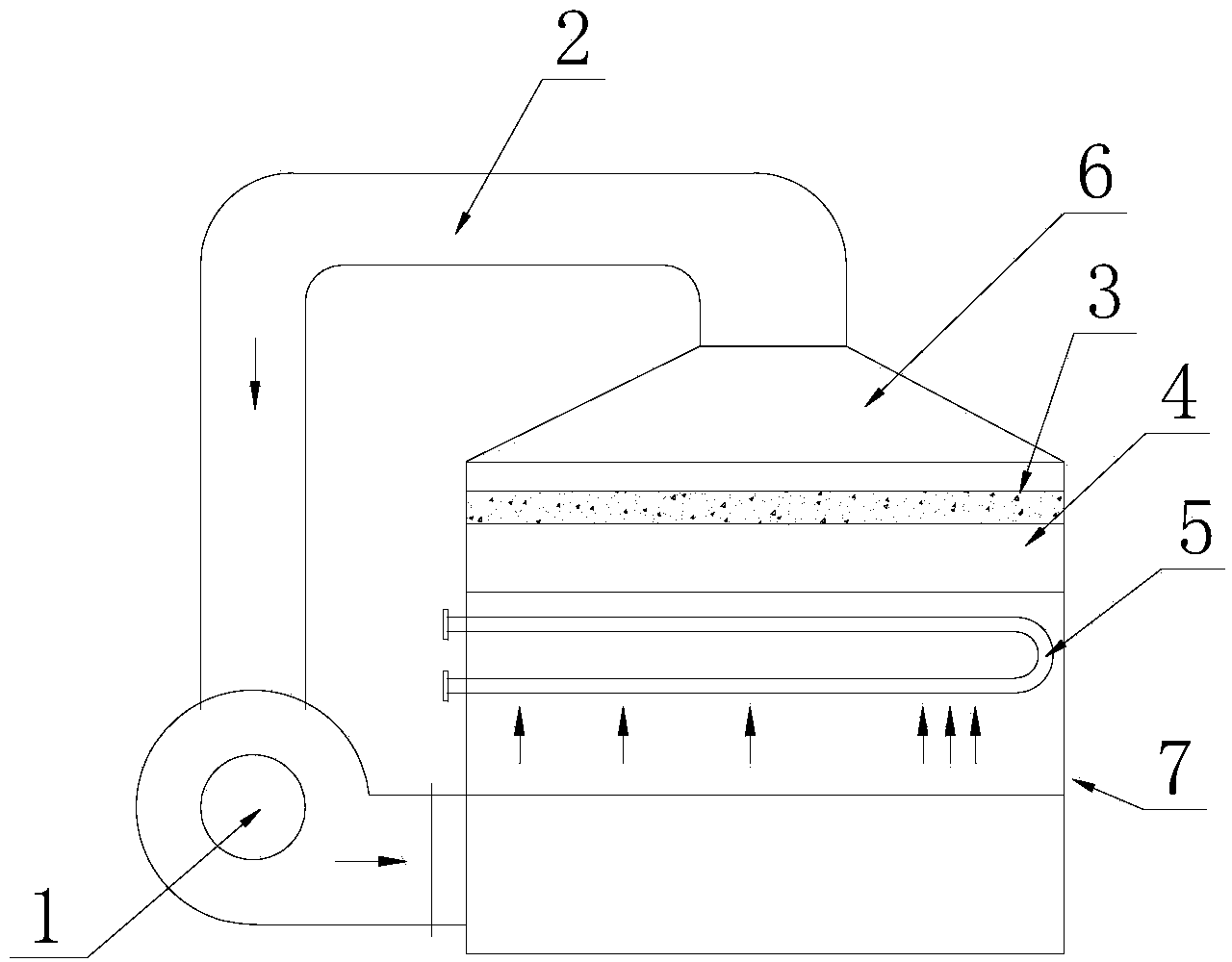

[0018] Such as figure 1 , figure 2 Shown is a uniform air heat setting oven, which includes a box body 7, a heater 5, a conveying chain plate 4, a suction hood 6, a return pipeline 2, a blower fan 1 and an even air device 8, and the conveying chain plate 4 is arranged on Inside the box 7, the heater 5 is arranged below the conveying chain plate 4, the air suction hood 6 is arranged above the conveying chain plate 4, the air suction hood 6 is connected to the return pipe 2, the return pipe 2 is connected to the fan 1, and the air uniform device 8 is provided At the bottom of the box body 7 , the fan 1 blows the return air out from the air uniform device 8 . Such as figure 2 As shown, there are two sets of the suction hood 6 , the return pipe 2 , the fan 1 and the air equalizer 8 respectively, and the air equalizers 8 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com