An automatic tape stripping machine

A technology of peeling machine and tape, applied in the directions of labeling machine, labeling, lamination auxiliary operation, etc., can solve the problems of wasting labels, missing peeling, and low efficiency of labeling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

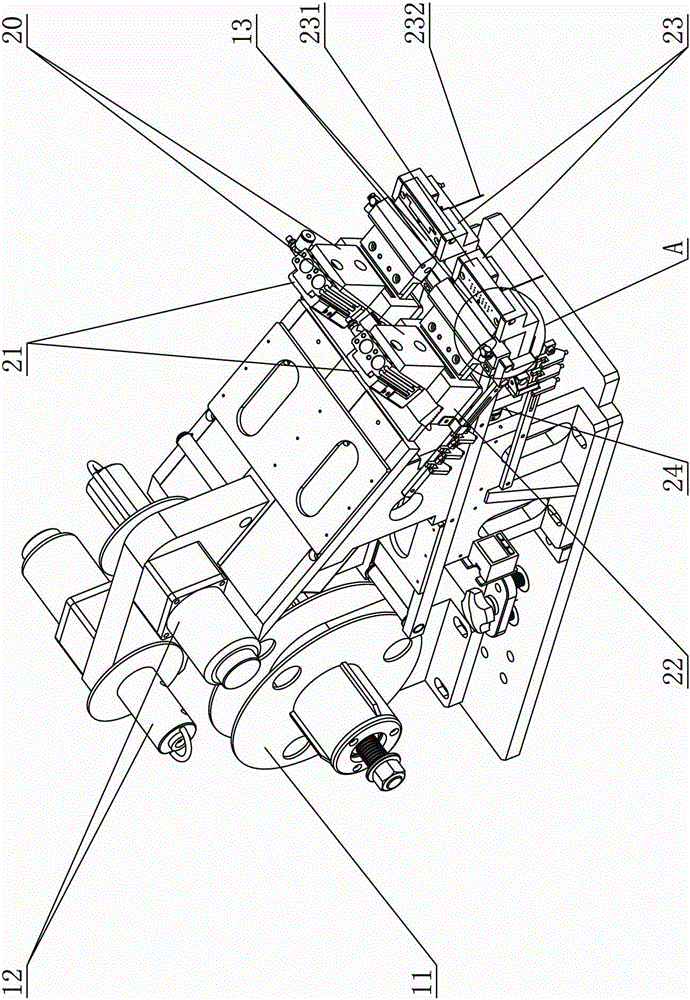

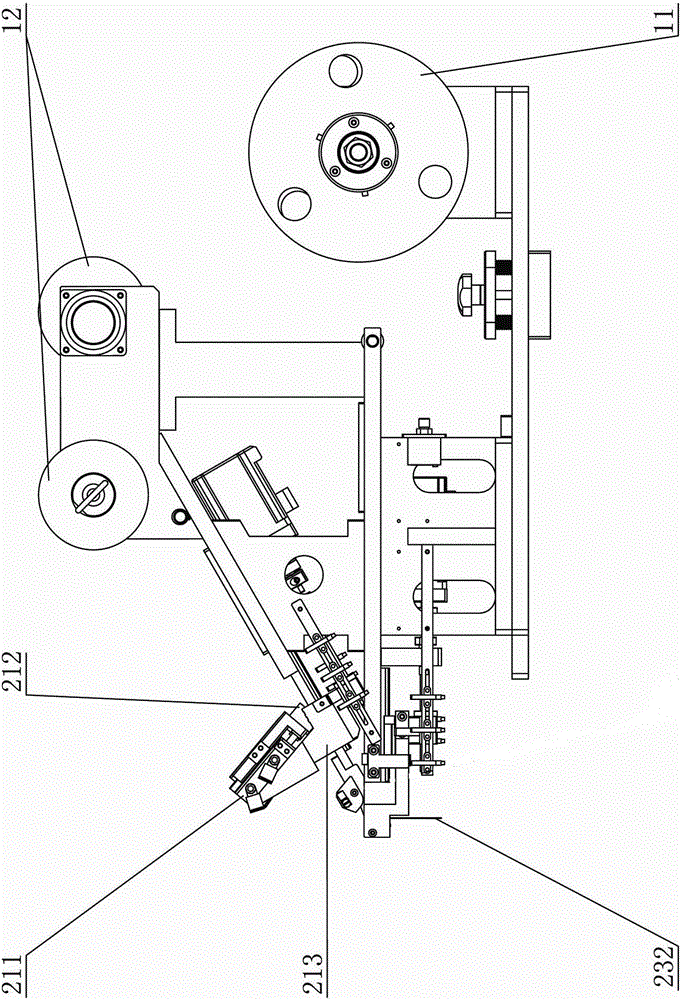

[0016] Such as figure 1 Shown, a kind of automatic adhesive tape peeling machine comprises material tape fixing device 11, material receiving device 12, stripping knife 13 and is located at the pulling device 20 between described material receiving device 12 and described stripping knife 13, so The material pulling device 20 includes a pressing mechanism 21 and a first translation mechanism 22 that drives the movement of the pressing mechanism 21. The angle formed by the plane and the plane where the first translation mechanism 22 moves is an acute angle.

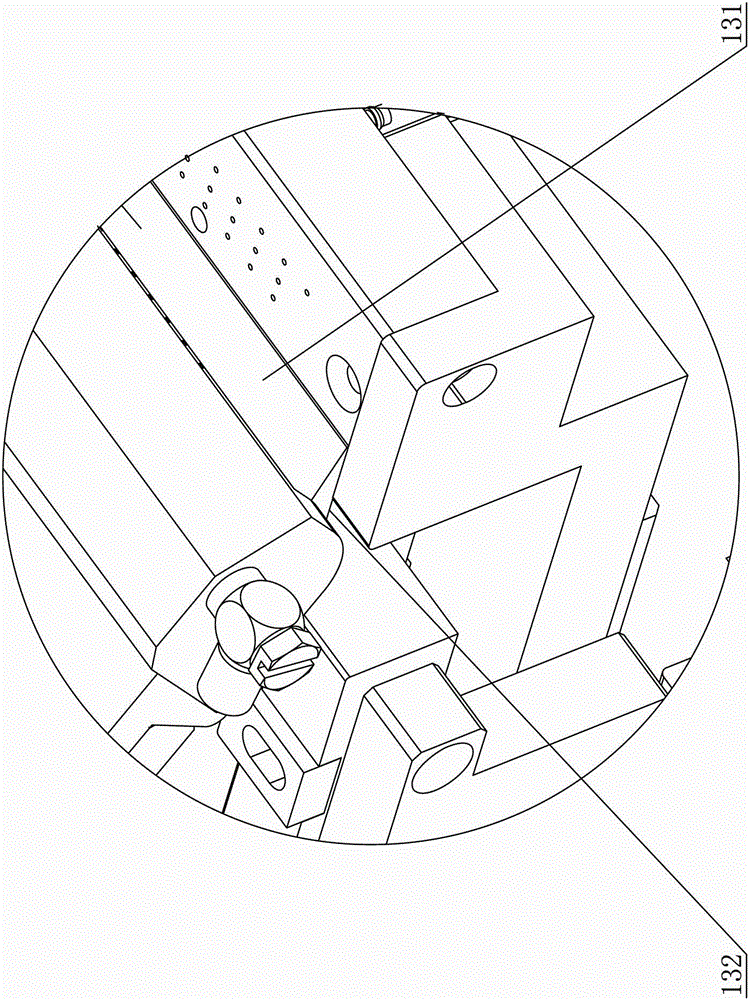

[0017] Such as figure 1 , 2 As shown, the peeling knife 13 includes a first peeling surface 131 and a second peeling surface 132, and the angle formed by the first peeling surface 131 and the plane where the first translation mechanism 22 moves is smaller than the first peeling surface 131. The angle formed by the two peeling surfaces 132 and the plane where the first translation mechanism 22 moves, the second peeling su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com