Detachable integral slat trailing edge structure

A detachable, slatted technology, applied in multi-layer structures, wings, aircraft parts, etc., can solve the problems of high cost, inability to disassemble, weak bonding surface strength, etc., to achieve easy maintenance and replacement, less structural parts, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

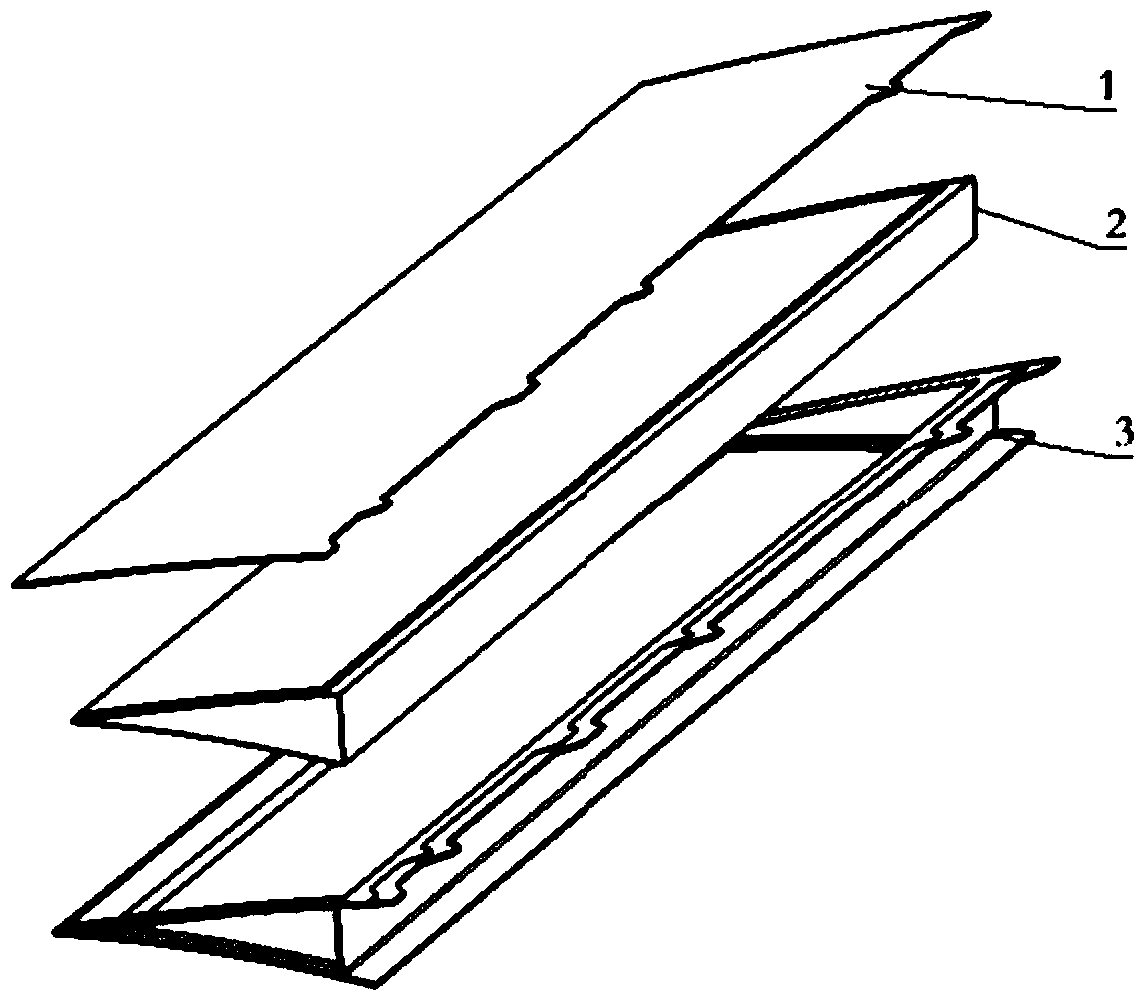

[0017] The overall detachable slat trailing edge structure is in the shape of a triangular wedge, and is composed of an upper wall plate 1 , a composite frame 2 and a foam core 3 .

[0018] The upper wall panel 1 is paved with CF3052 carbon fiber fabric, and a layer of aluminum mesh is arranged on the outermost layer to prevent lightning strikes.

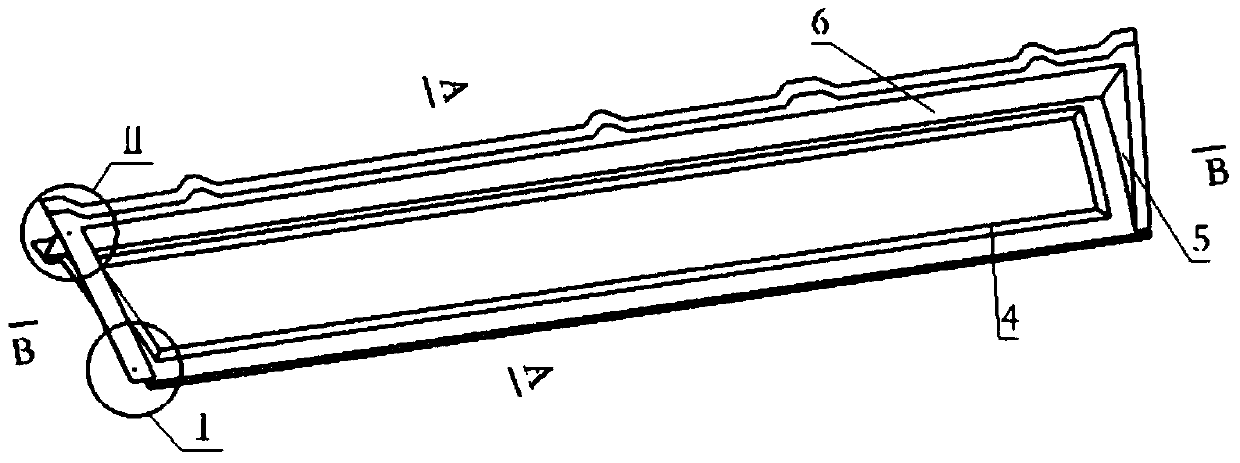

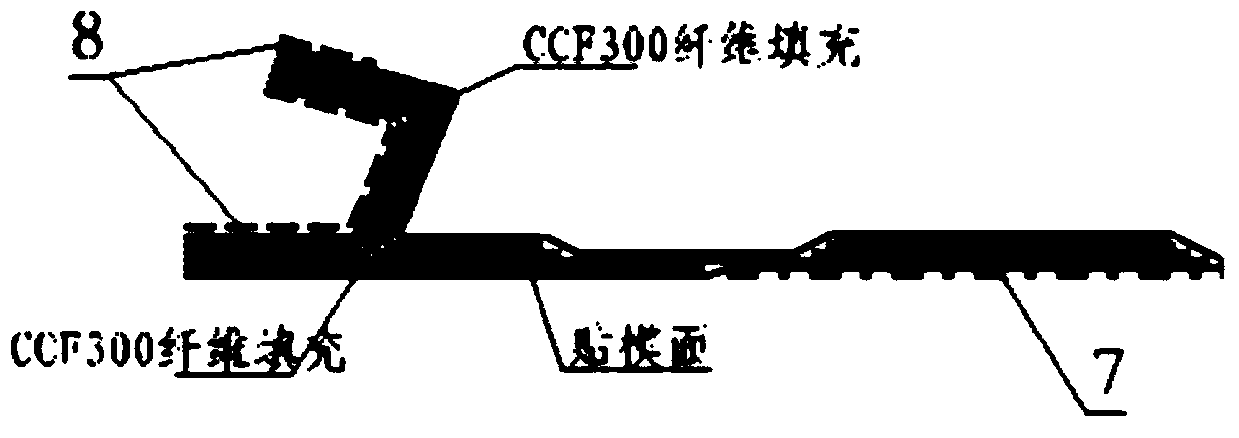

[0019] The composite frame 2 is made of CF3052 carbon fiber fabric interlaced to form its lower skin 4, sealing ribs 5, and partitions 6. The outermost layer of the lower skin 4 is arranged with a wear-resistant plate 7 to prevent and fix the front edge 11 The contact causes the trailing edge to wear. For spanwise and chordwise layups, see figure 2 , image 3 , and fill the gap formed by the two layers of fabric corners shown in the figure with CCF300 fiber filler. The sealing ribs meet at the lowest point of the airfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com