Variable-frequency and variable-amplitude vertical vibration device of block forming machine

A block forming machine, vertical vibration technology, applied to ceramic forming machines, manufacturing tools, etc., can solve problems such as selection, limited raw material adaptability, gear wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

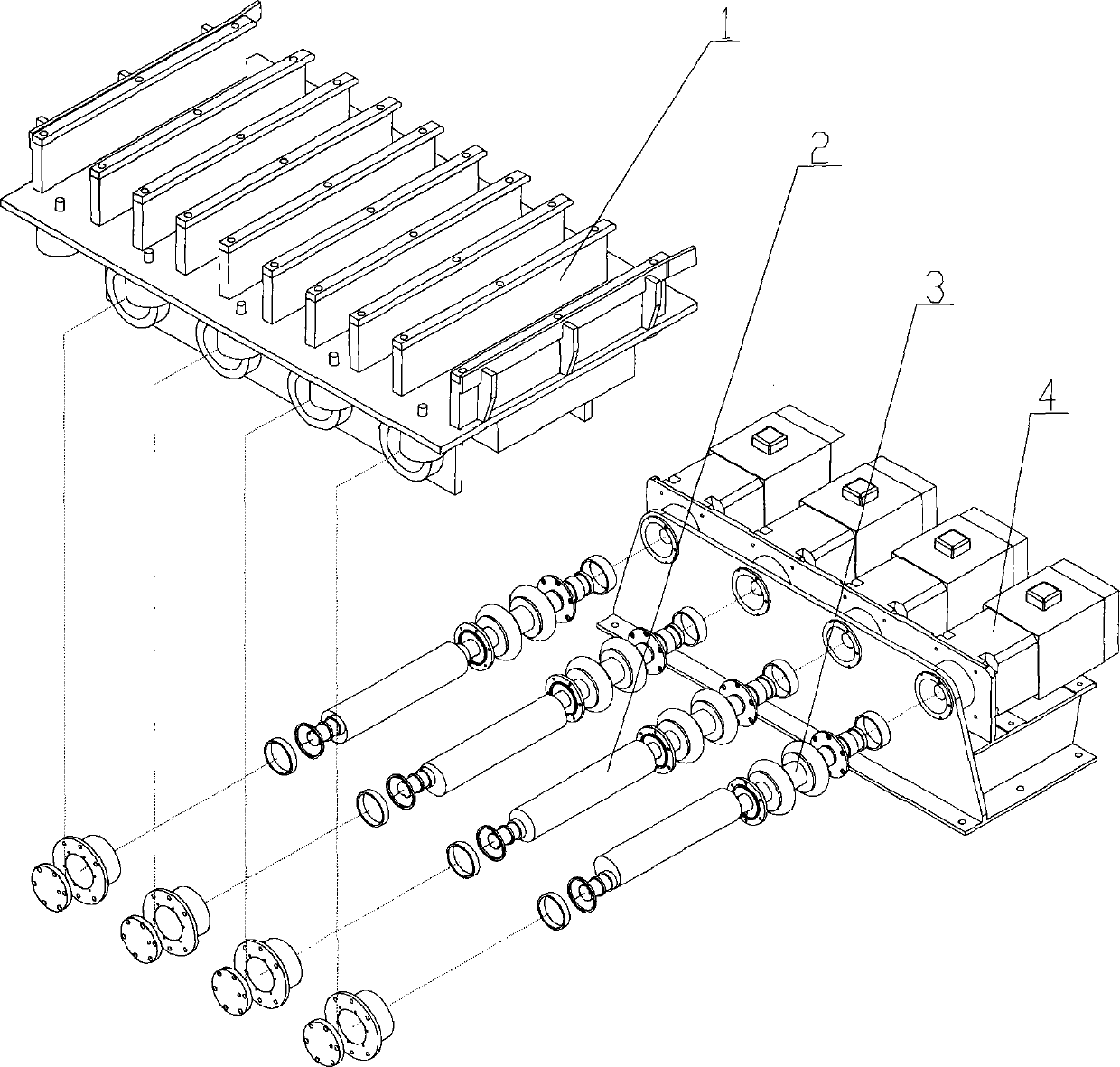

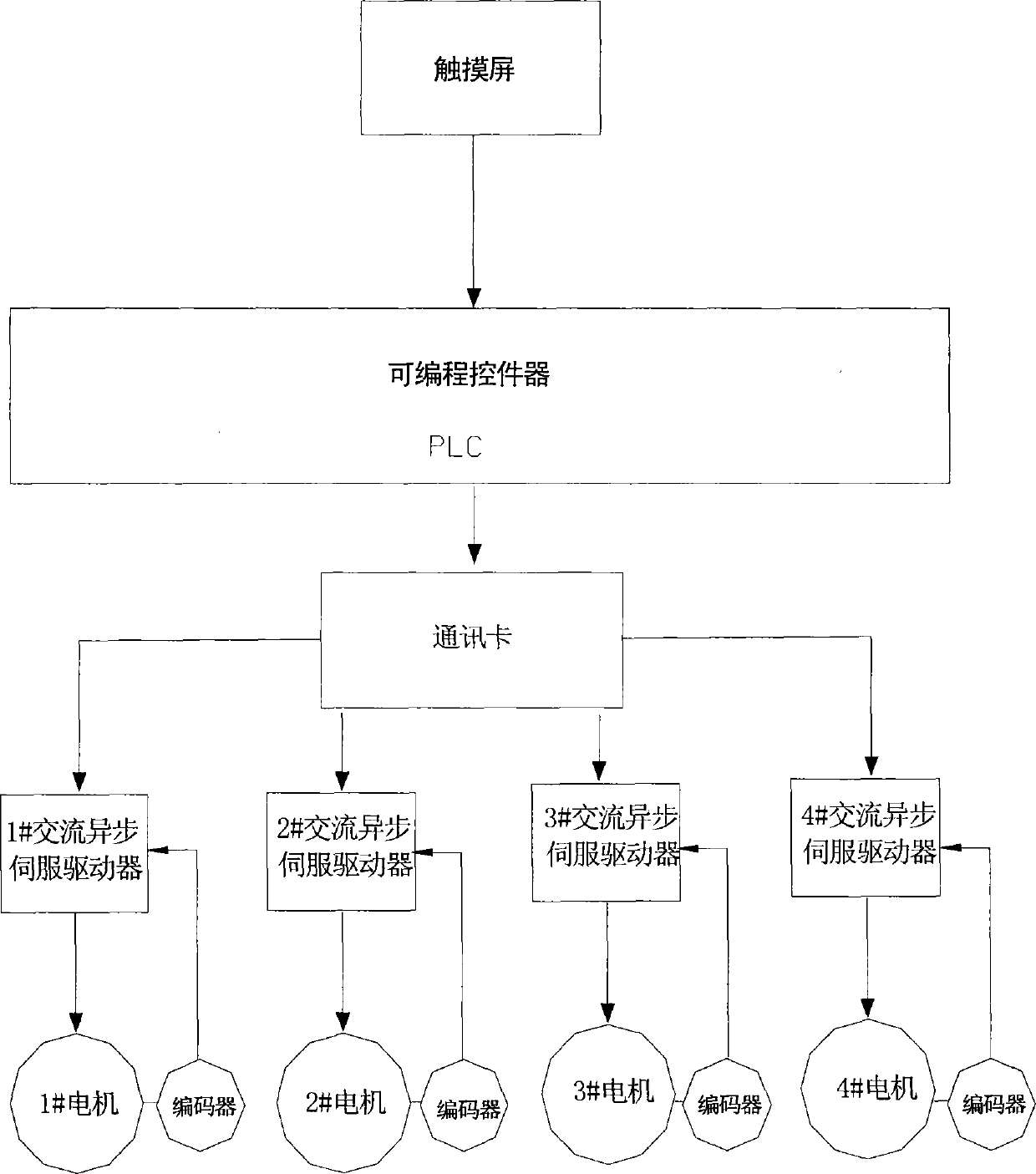

[0012] The present invention will be further described below in conjunction with accompanying drawing, is made of electric control part and mechanical part. The electric control part has a touch screen, a programmable logic controller, a communication card and an AC asynchronous servo driver. The interconnection constitutes the electronic control part. The mechanical part consists of a vibrating table 1 and four vibrating units. Each vibration unit is composed of an eccentric shaft 2 , a flexible coupling 3 and a motor 4 . There are four eccentric shaft holes under the vibrating table 1, and an eccentric shaft 2 is provided in each eccentric shaft hole. There is a flexible shaft coupling 3 at the coupling end of the eccentric shaft and the motor. The eccentric shaft is connected with the output shaft of the motor through a flexible coupling. Equipped with AC asynchronous servo drive on each motor. The four rotating units are divided into two groups, and the two inner unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com