Planet type cleaning device

A cleaning device and planetary technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as separation of solutions from plate-shaped porous structural parts, and achieve the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

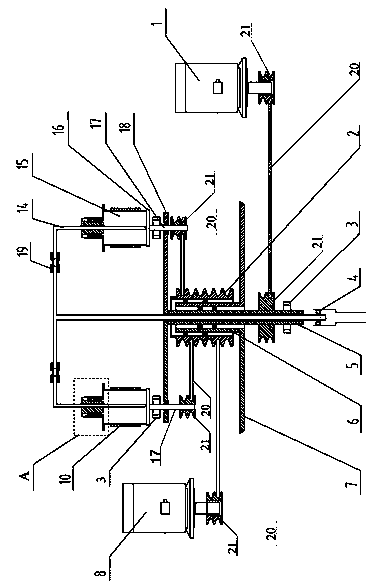

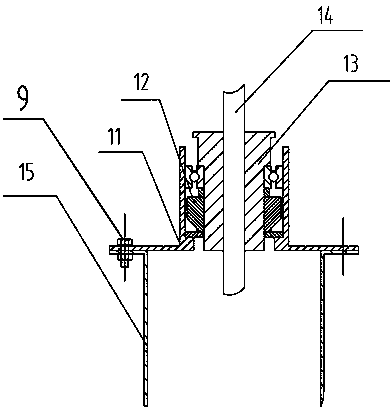

[0028] Below, a planetary cleaning device of the present invention will be described in detail with reference to the accompanying drawings and embodiments:

[0029] Such as figure 1 , 2 As shown, a planetary cleaning device comprises a revolution motor 1, a revolution shaft 5, a revolution turntable 18, an autorotation motor 8, an autorotation shaft 17 and an autorotation turntable 16, and the revolution motor 1 passes through a transmission of a belt 20 and a pulley 21 and the revolution shaft 5 connection, the revolving shaft 5 is fixedly connected with the revolving turntable 18, the revolving turntable 18 is connected with the rotation shaft 17 through the bearing, the rotation motor 8 is connected with the intermediate pulley 2 through the transmission of the belt 20 and the pulley 21, and the intermediate pulley 2 passes through the belt 20 The drive with the pulley 21 is respectively connected with two rotation shafts 17, the rotation shaft 17 is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com